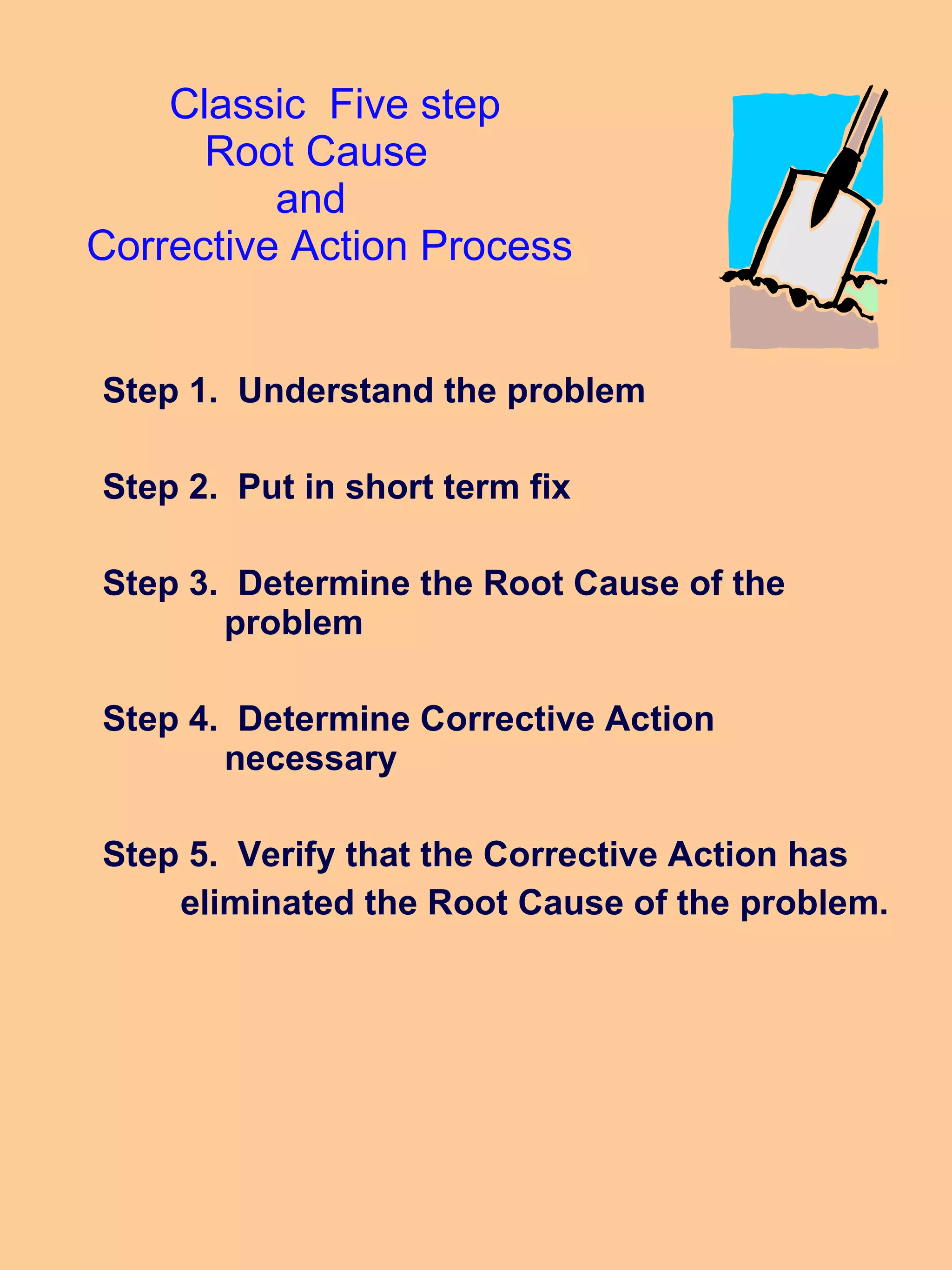

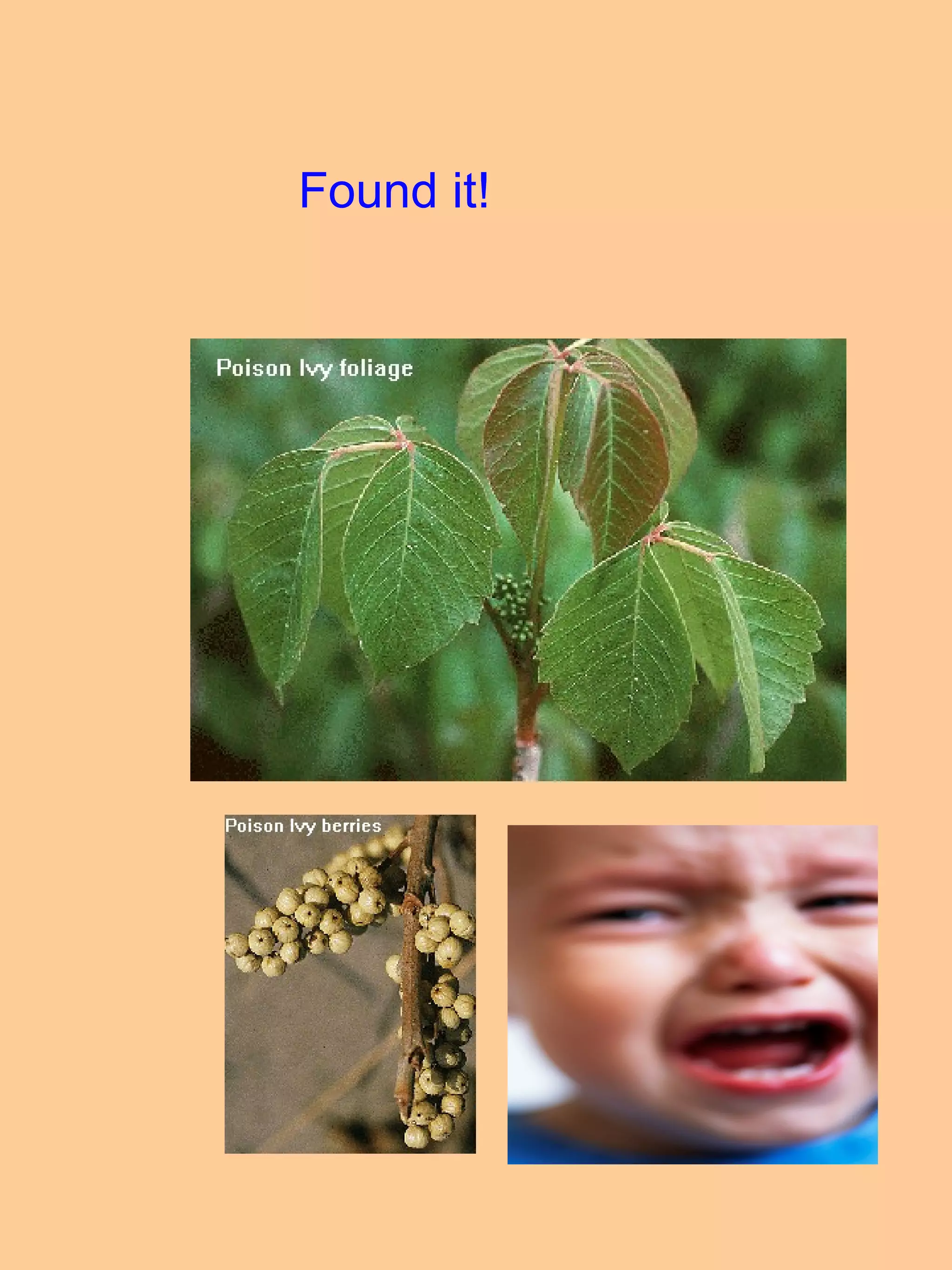

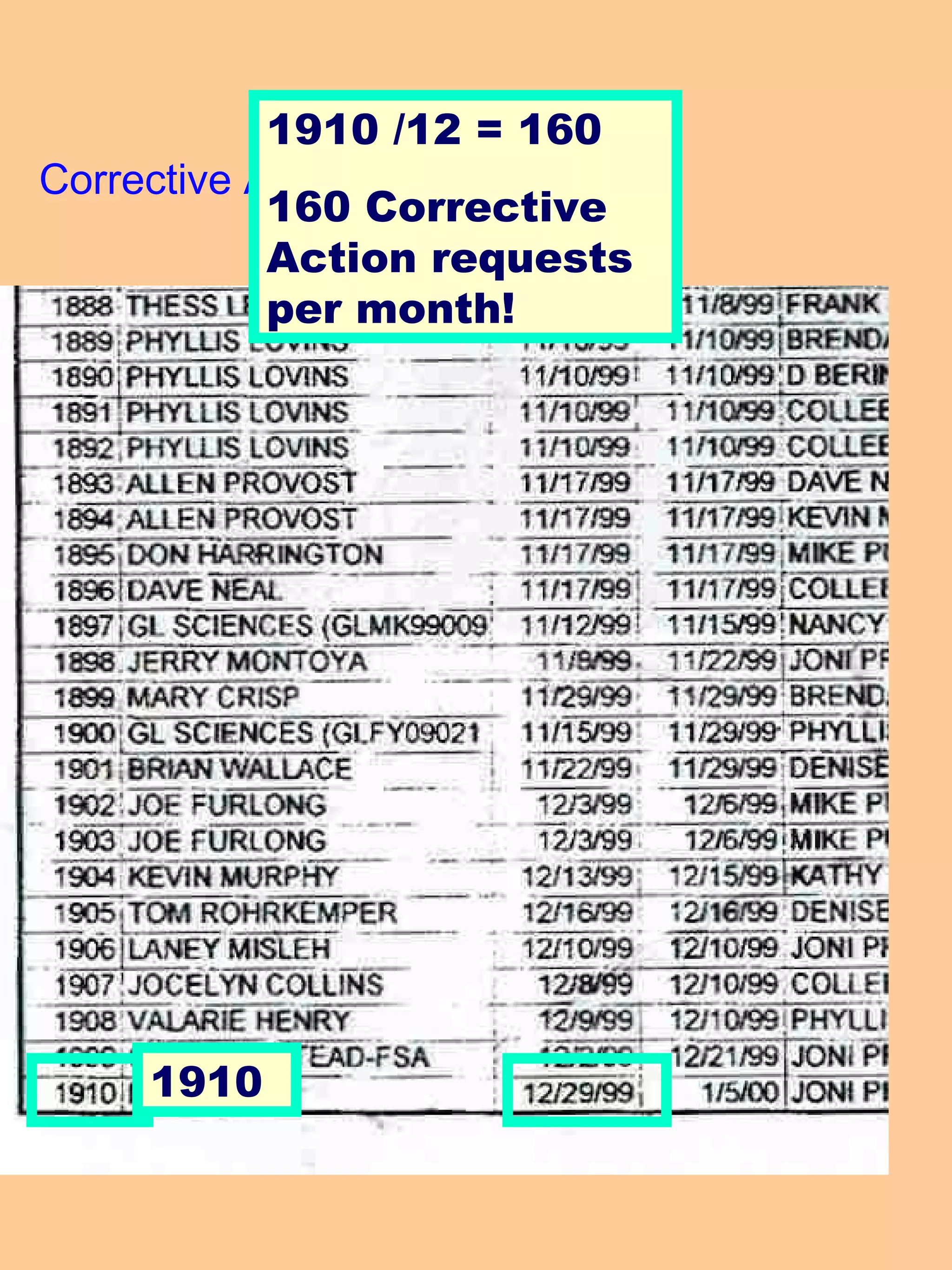

The document describes the five-step root cause and corrective action process, including understanding the problem, implementing a short-term fix, determining the root cause, determining and implementing a corrective action, and verifying the corrective action addressed the root cause. It also details an eight-step process for developing corrective actions, such as developing alternatives, selecting the best solution, establishing a plan, timing, details, documentation, approval, and implementation. The goal of corrective action is to permanently eliminate problems.

![Prerequisite: Quality Management System [ISO 9000 (1994)] Management Responsibility Quality System Contract Review Design Control Document & Data Control Purchasing Control of Customer-Supplied Product Product Identification & Traceability Process Control Inspection & Testing Control of Inspection, M & TE Inspection & Test Status Control of Non-Conforming Product Corrective & Preventive Action Handling, Storage, Packaging Control of Quality Records Internal Quality Audits Training Servicing Statistical Techniques This is the way we do business to have Quality!](https://image.slidesharecdn.com/rootcauseandcorrectiveactionworkshopcinciasq2009-12577931505954-phpapp02/75/Root-Cause-And-Corrective-Action-Workshop-Cinci-Asq-2009-7-2048.jpg)