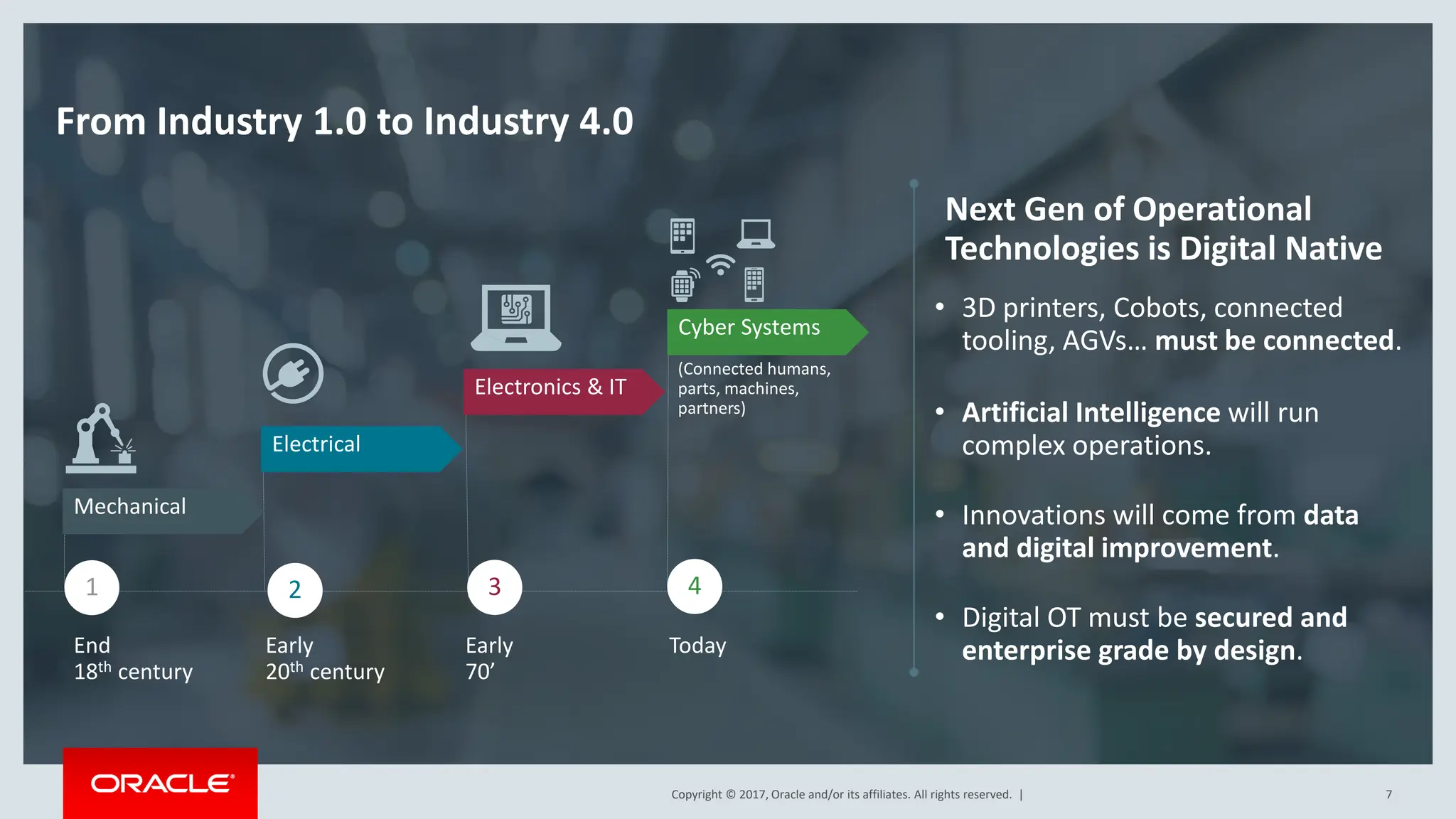

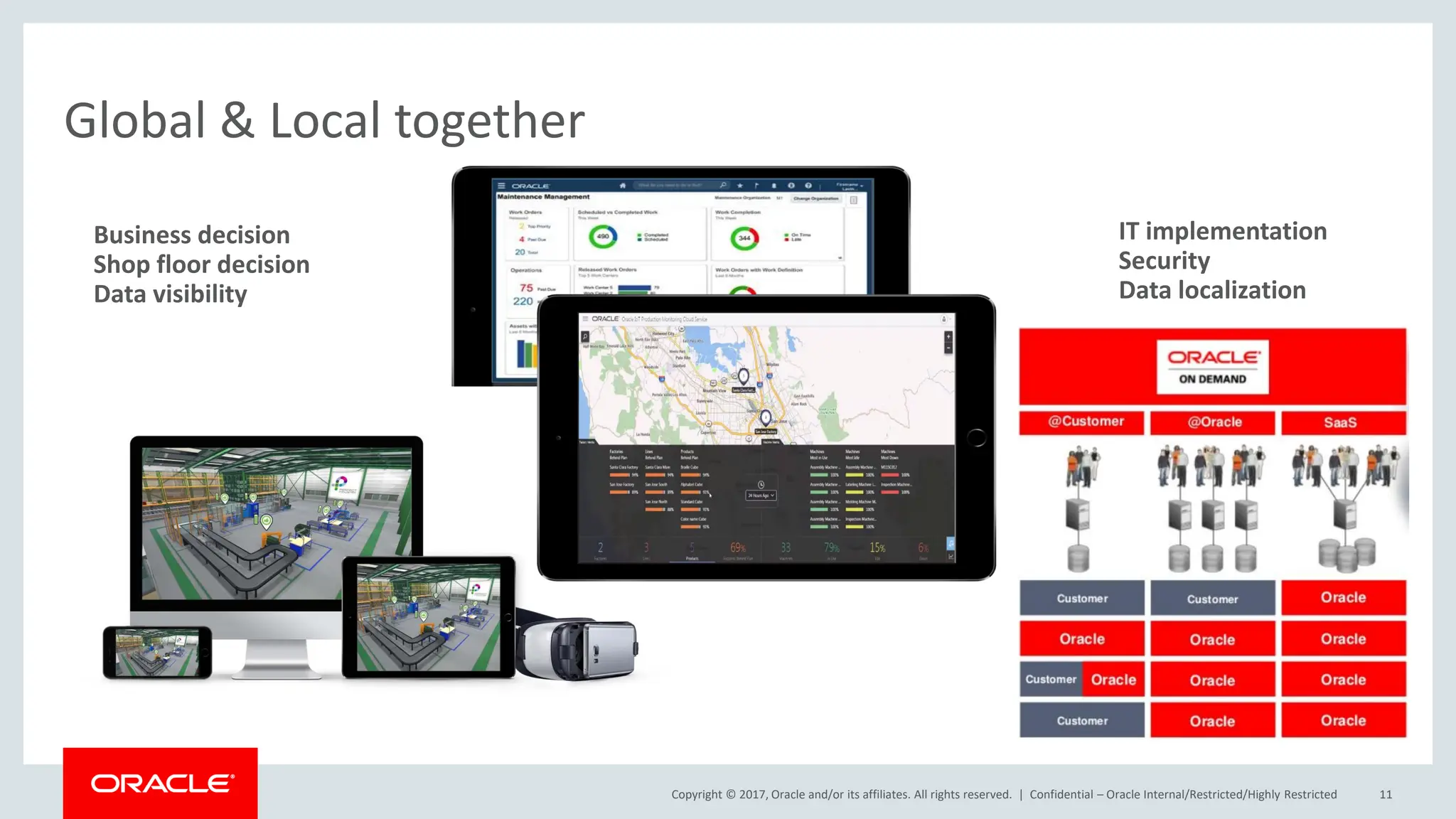

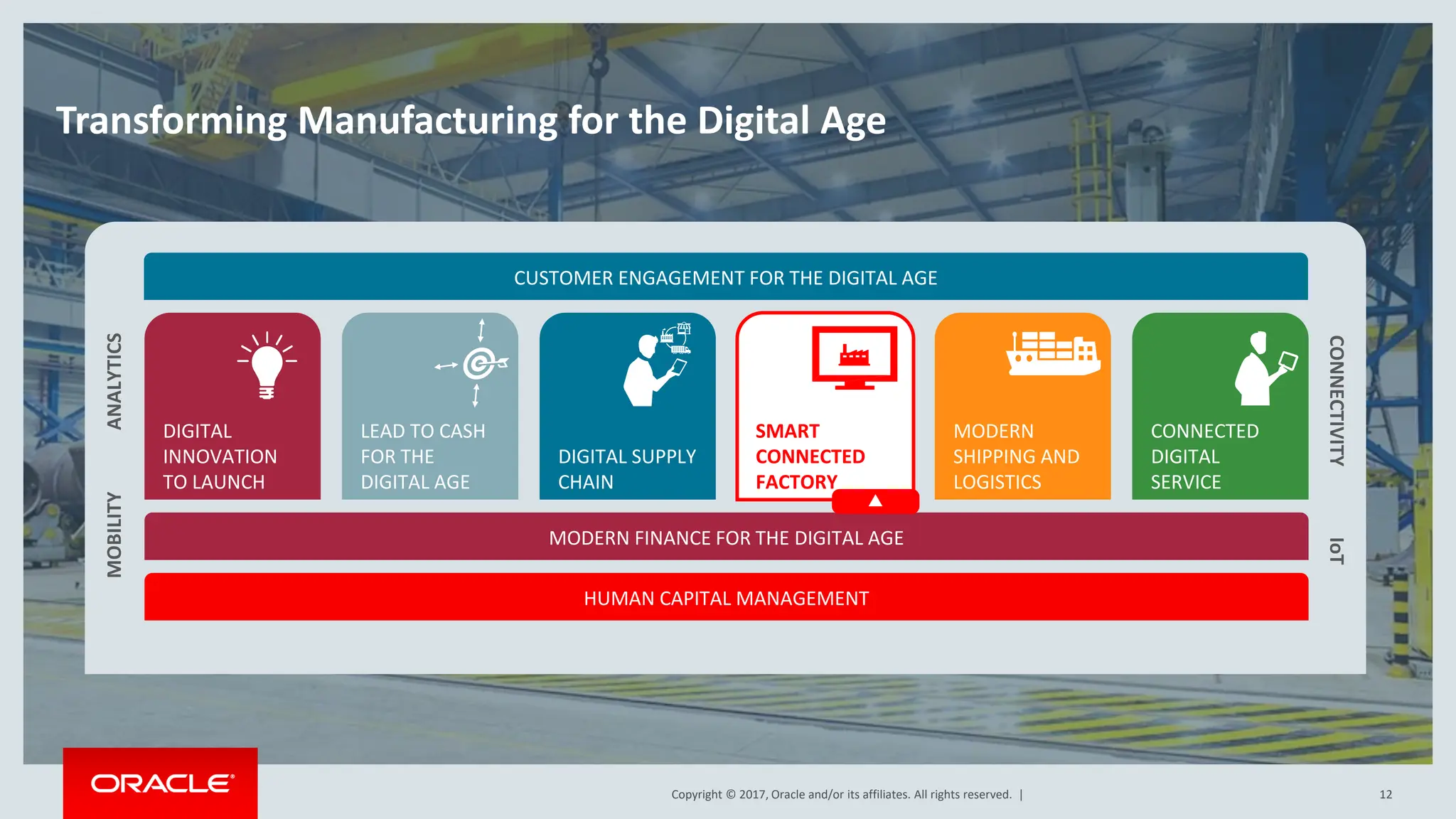

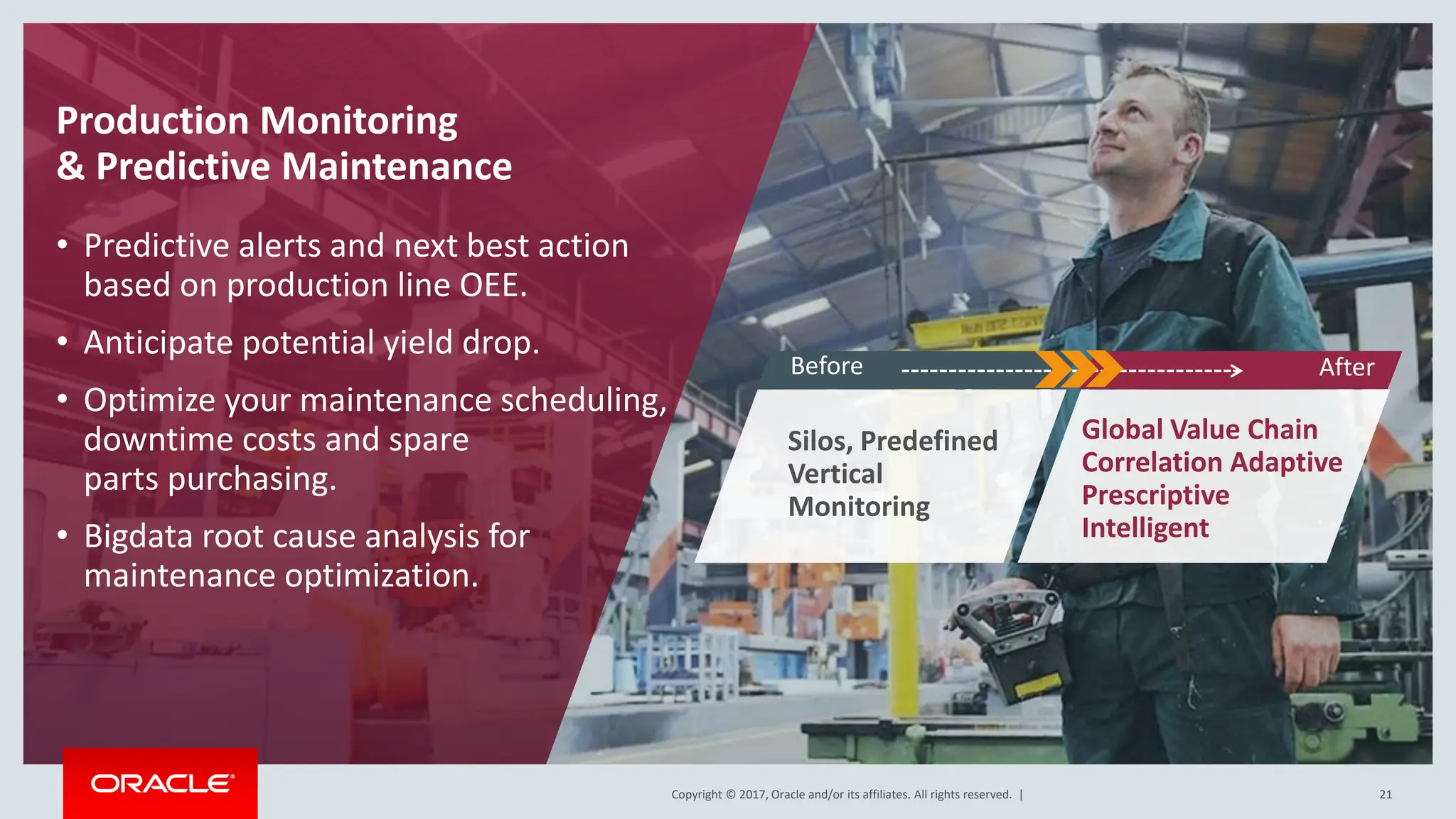

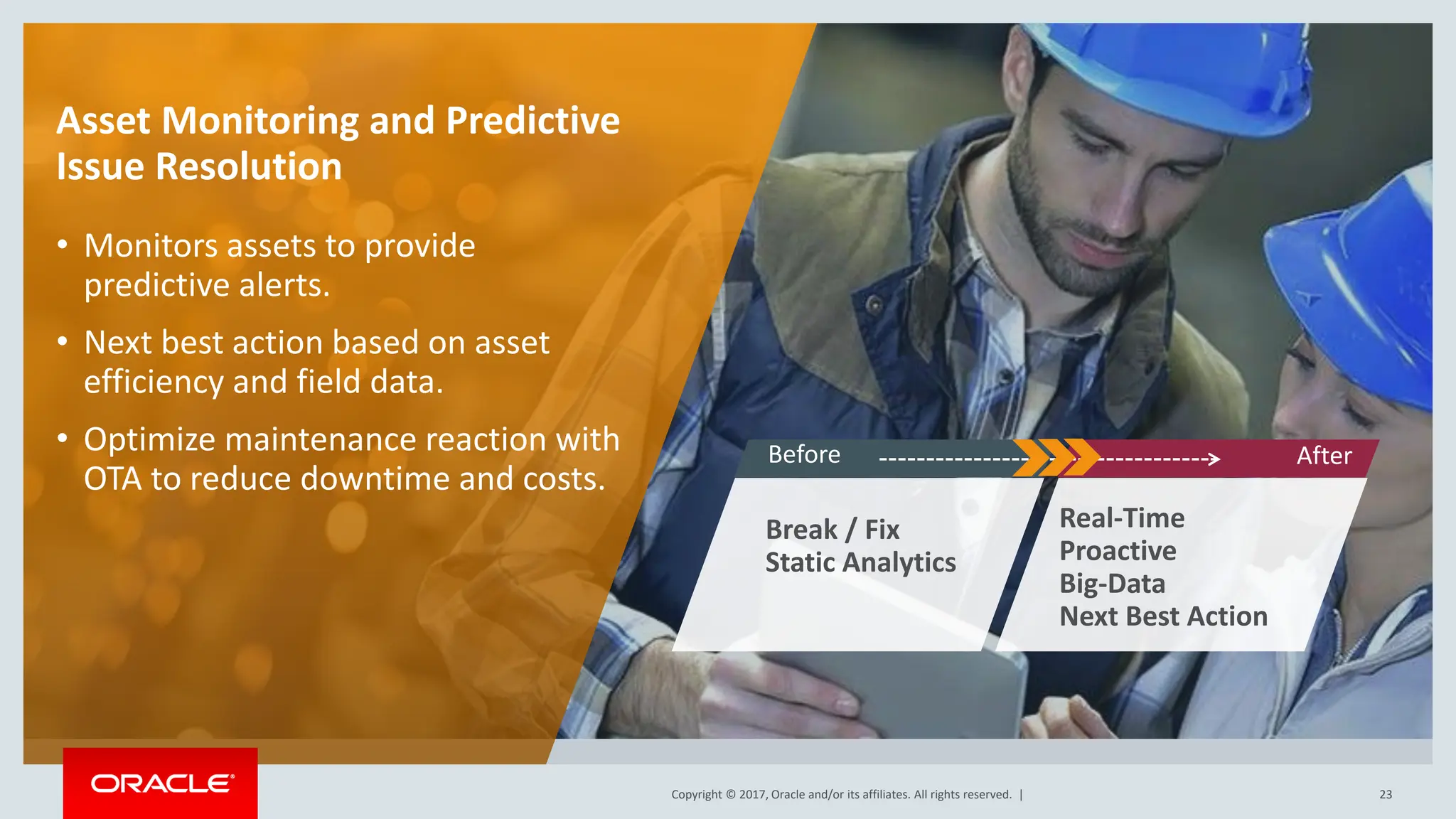

The document discusses the impact of the 4th Industrial Revolution on manufacturing and supply chains, emphasizing the role of digital technologies such as IoT, AI, and cloud solutions. It highlights the necessity for enhanced data integration and visibility to optimize decision-making processes in a complex operational environment. Additionally, it suggests that the success of modern manufacturing relies on continuous innovation, collaboration, and the effective use of digital assets to drive operational improvements.