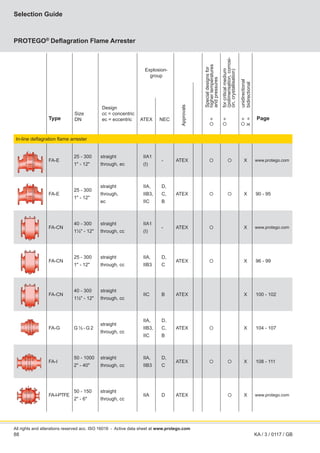

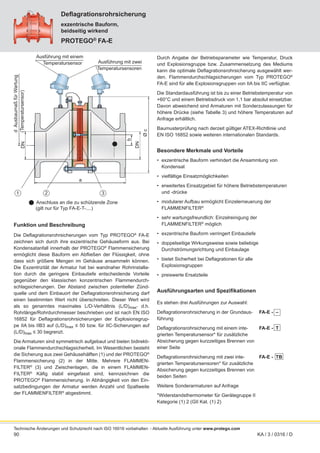

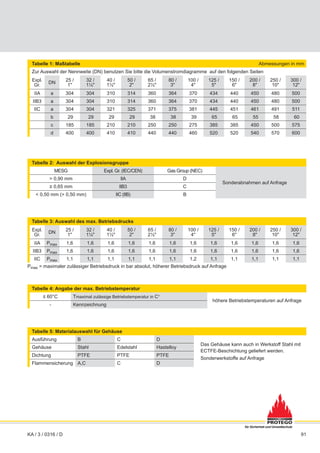

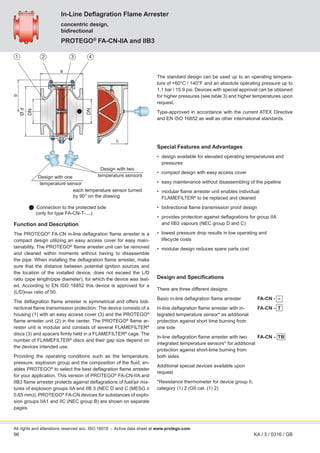

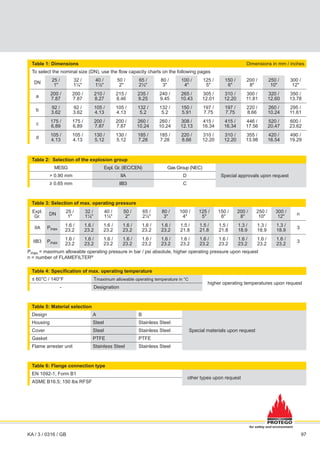

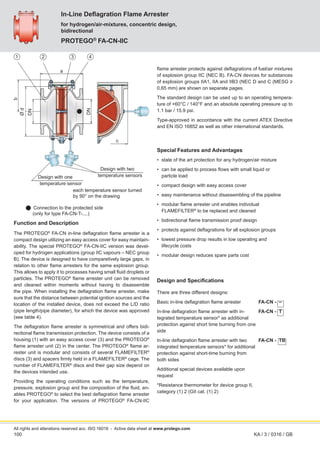

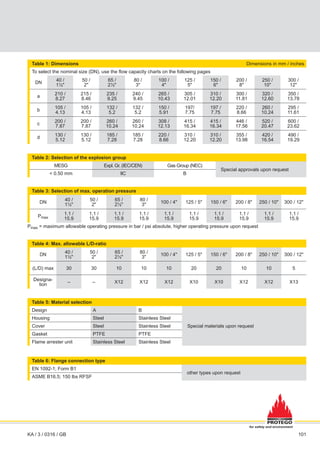

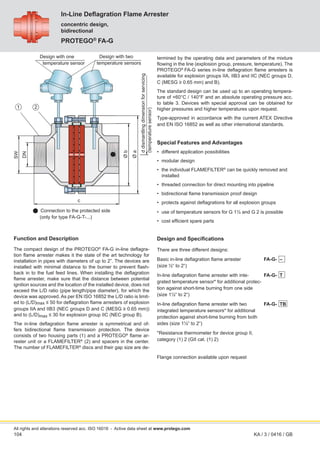

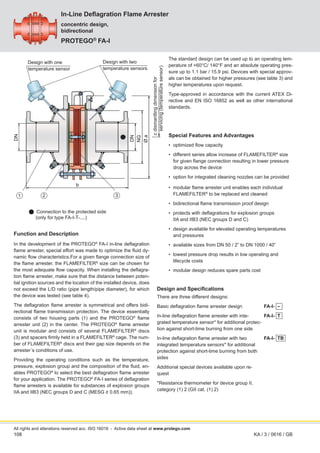

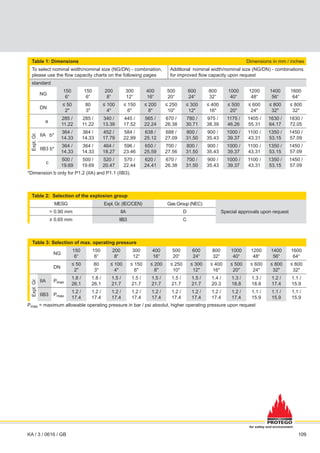

This document provides information on PROTEGO deflagration flame arresters. It discusses their function of extinguishing flames in pipelines to protect equipment from deflagrations. It describes the modular design of the flame arrester unit and selection of the appropriate type and size based on the process parameters and explosion group of gases. Guidelines are provided on sizing, installation, selection, applications, and special designs available for critical services.