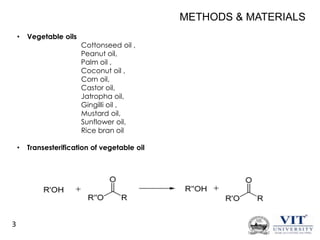

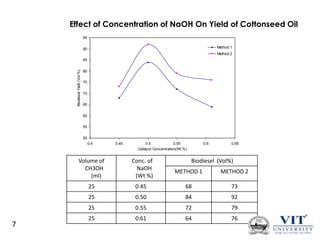

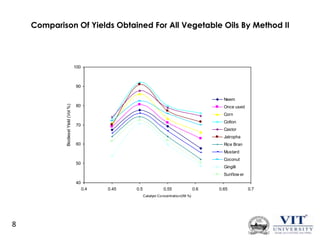

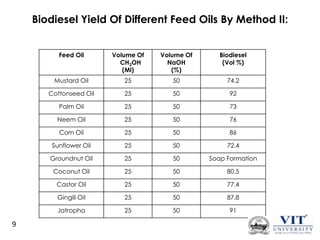

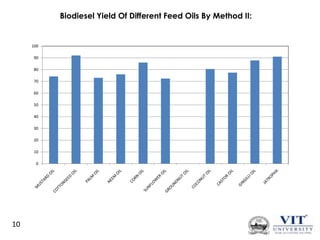

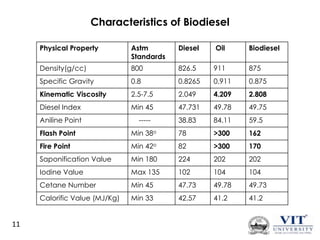

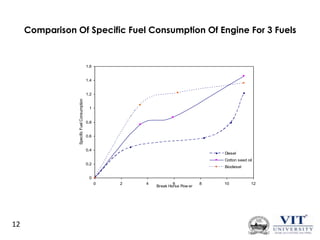

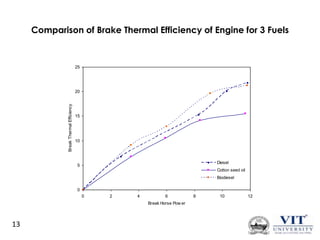

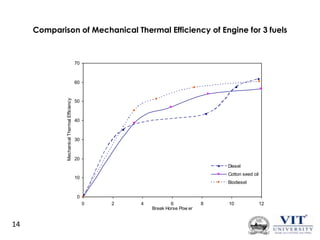

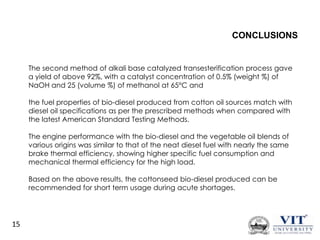

This document summarizes research conducted on producing and analyzing biodiesel obtained from cottonseed oil. The researchers used two transesterification methods to produce biodiesel from various vegetable oils including cottonseed oil. They analyzed the effects of catalyst concentration on biodiesel yield and compared properties and engine performance of biodiesel to diesel. Their results showed the second method achieved over 92% yield from cottonseed oil. Properties of the cottonseed biodiesel matched diesel specifications. Engine tests showed performance similar to diesel with higher fuel consumption for biodiesel. They concluded cottonseed biodiesel is recommended for short term use during fuel shortages based on their results.