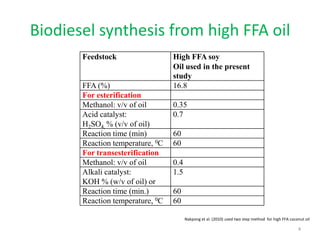

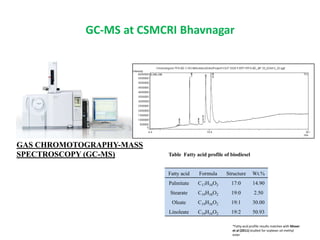

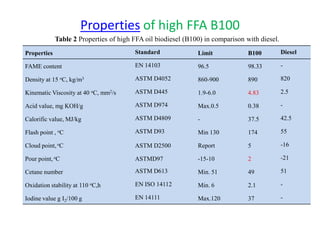

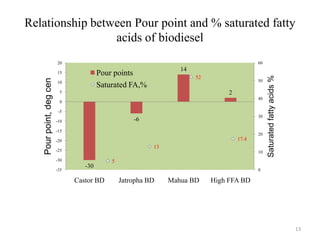

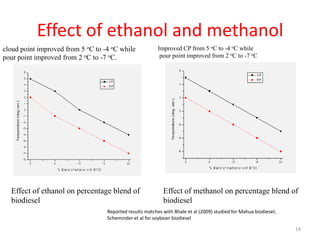

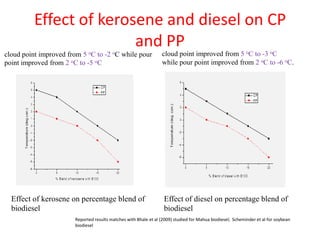

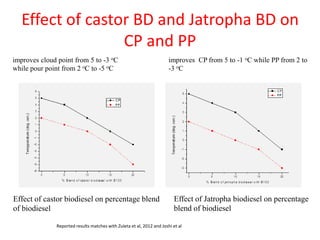

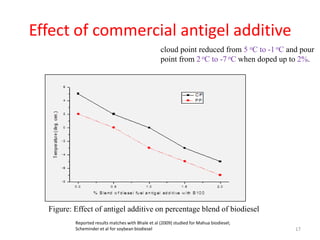

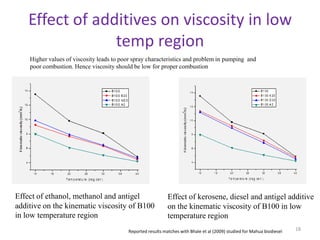

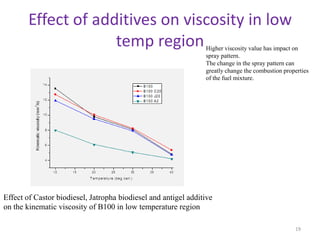

This document summarizes an experimental study on improving the low temperature properties of biodiesel produced from high free fatty acid soy oil. The study tested blending the biodiesel with ethanol, methanol, kerosene, diesel, castor biodiesel, jatropha biodiesel, and adding a commercial antigel additive. Results showed blending with ethanol and methanol up to 20% improved cloud point and pour point the most. Adding 2% of the commercial additive also significantly improved low temperature properties. The conclusions were that ethanol, kerosene, and commercial additives can effectively enhance the cold flow properties of the high free fatty acid biodiesel, making it usable in colder climates.