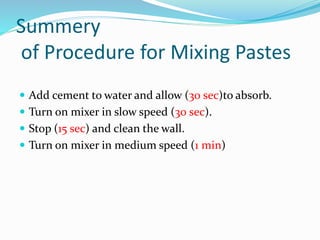

This document provides procedures for mechanically mixing hydraulic cement pastes and mortars. The paste procedure involves adding cement to water and allowing it to absorb for 30 seconds before mixing at slow speed for 30 seconds and then medium speed for 1 minute, stopping to scrape the sides after 15 seconds. The mortar procedure involves adding cement to water and mixing at slow speed for 30 seconds, then adding sand over 30 seconds while mixing slowly. It is then mixed at medium speed for 30 seconds, allowed to rest for 1.5 minutes with scraping after 15 seconds, and given a final 1 minute medium mix.