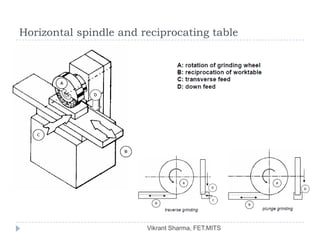

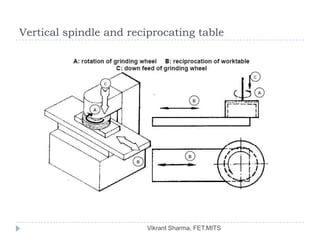

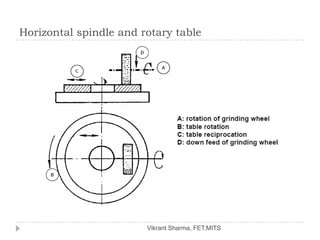

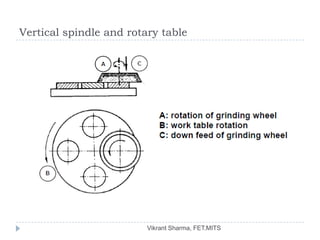

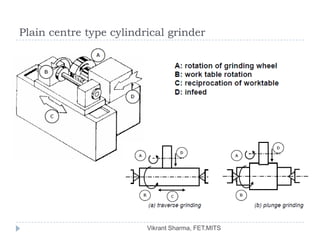

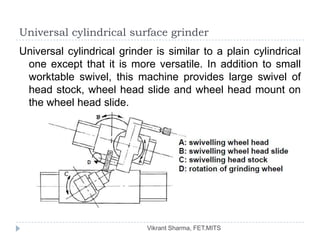

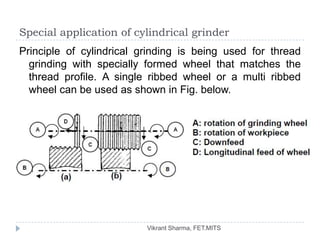

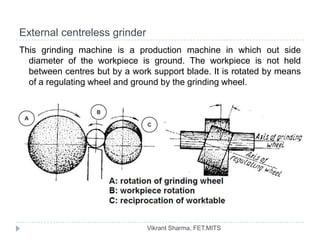

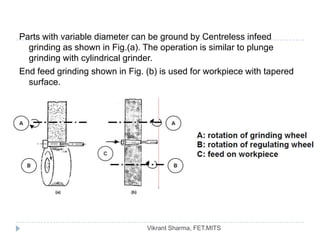

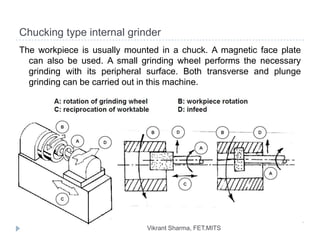

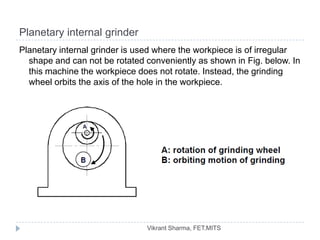

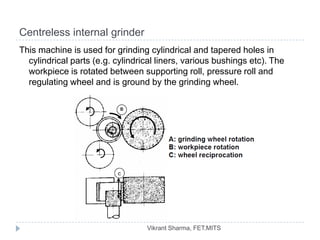

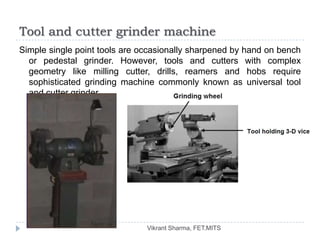

The document discusses different types of grinding machines. It describes surface grinding machines, cylindrical grinding machines, and internal grinding machines. Surface grinding machines are used to grind flat surfaces and can have horizontal or vertical spindles with reciprocating or rotary tables. Cylindrical grinding machines are used to produce external cylindrical surfaces and include plain, universal, and centerless types. Internal grinding machines grind internal cylindrical surfaces and include chucking, planetary, and centerless types. Tool and cutter grinding machines are used for complex tools.