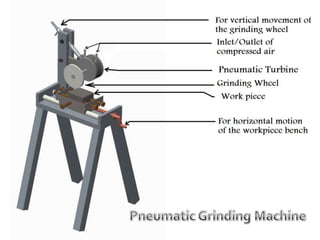

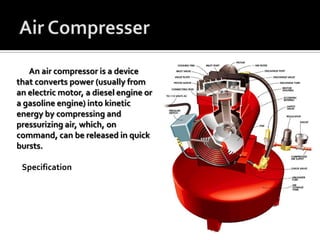

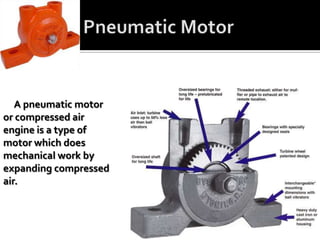

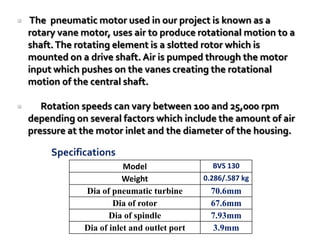

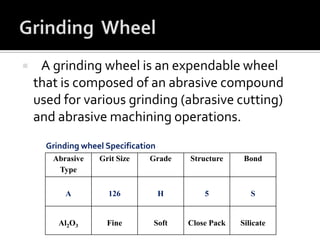

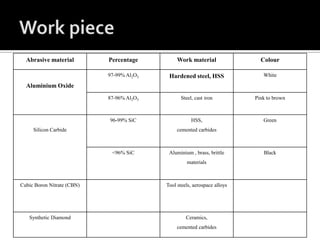

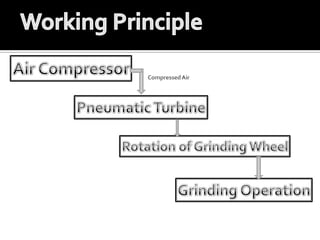

Umesh Kumar Meher discusses the design and working of a pneumatic grinding machine. The machine uses compressed air to power a rotary vane motor which turns the grinding wheel. It can grind metals and has advantages over electric grinders such as being portable, economical to operate, and producing less noise. However, it is less efficient than electric motors and more expensive due to the compressor. The document provides details on the specifications of the pneumatic motor, grinding wheel, and the working mechanism of the pneumatic grinding machine.