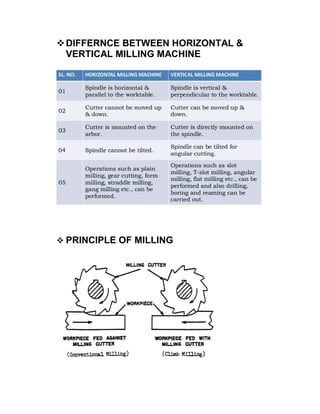

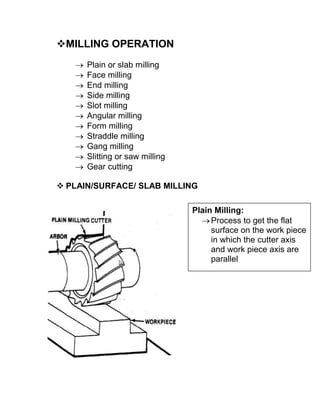

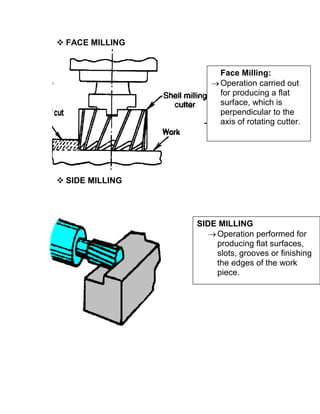

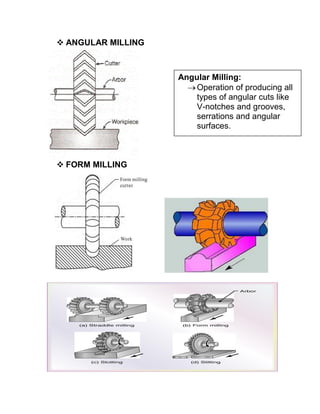

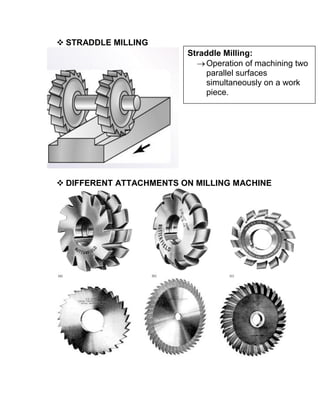

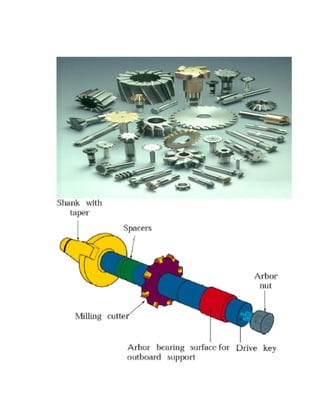

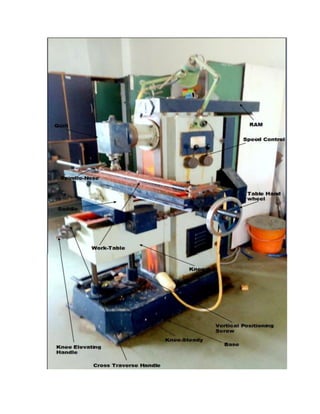

The document is a report on milling machines by Zala Milan. It defines milling and milling machines, describing that milling machines use a revolving cutter to machine flat, curved, or irregular surfaces on a workpiece mounted on a reciprocating table. It classifies milling machines as vertical or horizontal, and describes common milling operations like slab milling, face milling, end milling, and differences between horizontal and vertical milling machines.