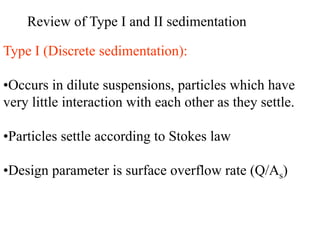

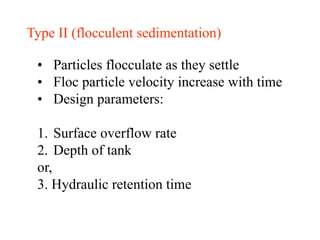

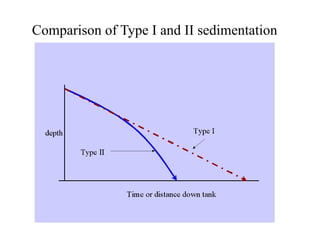

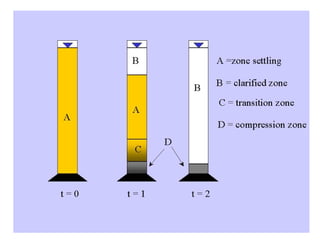

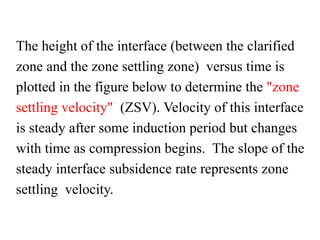

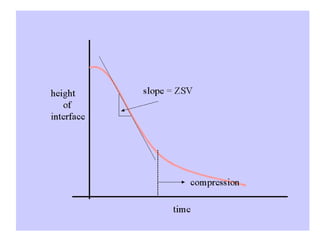

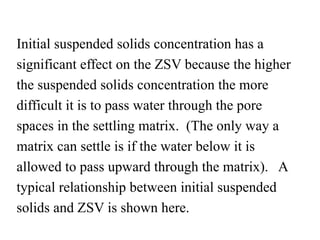

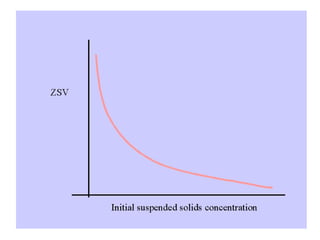

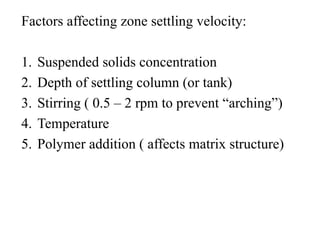

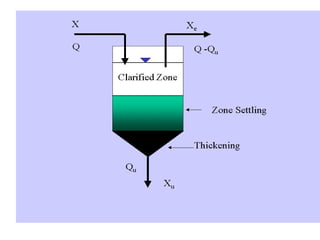

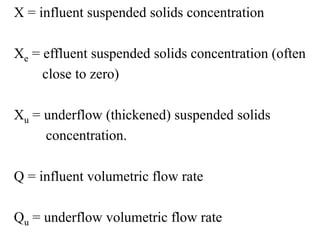

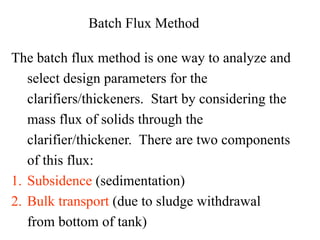

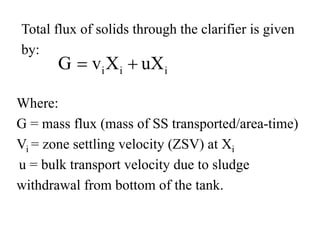

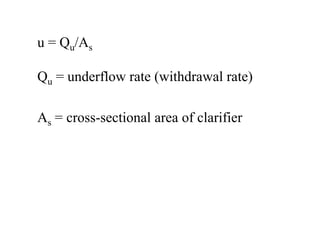

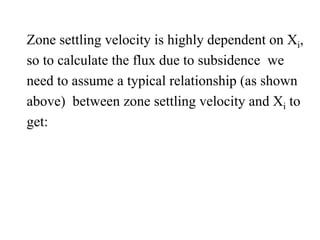

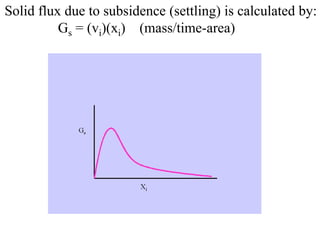

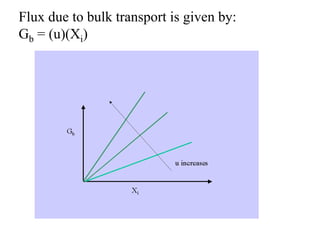

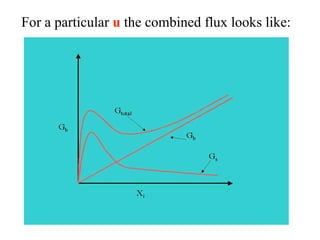

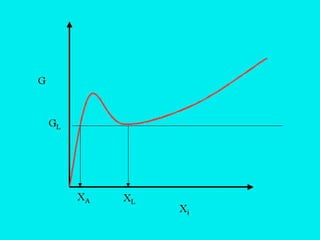

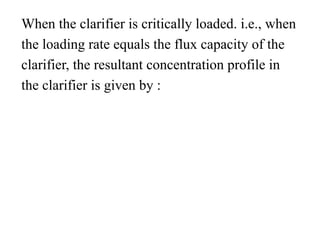

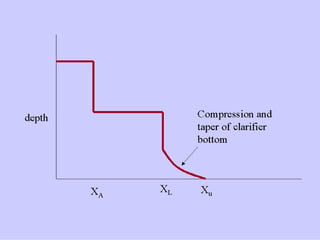

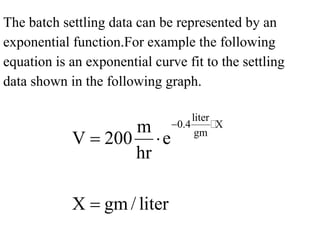

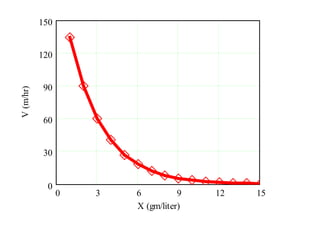

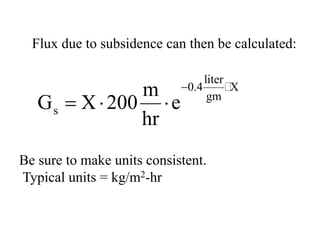

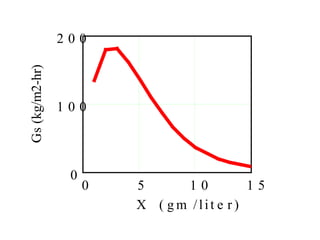

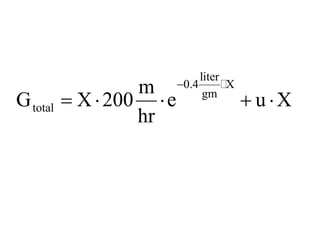

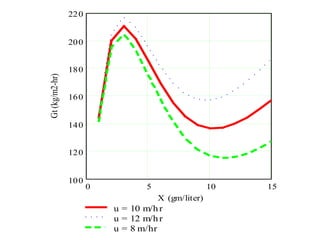

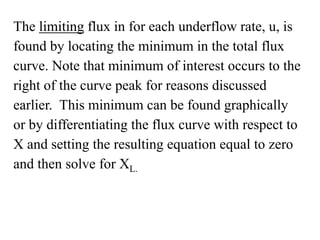

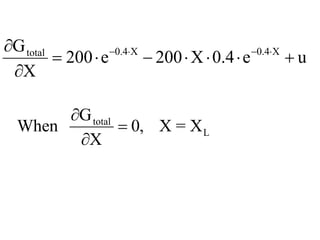

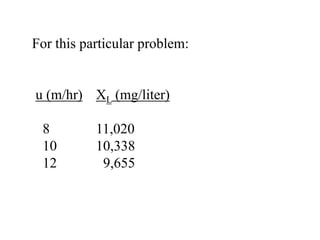

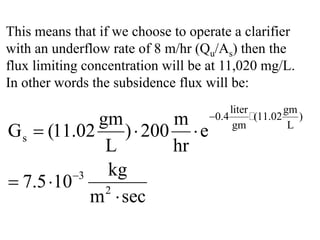

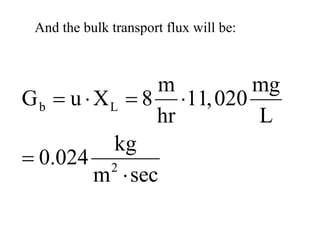

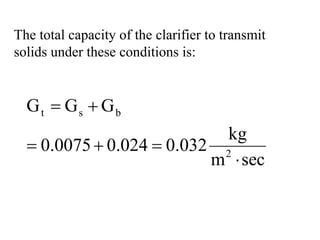

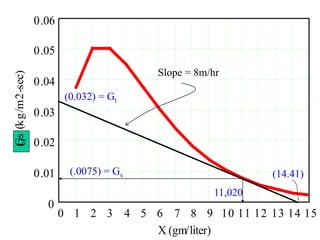

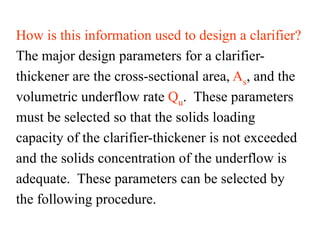

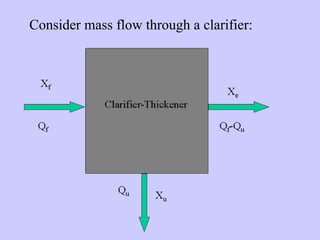

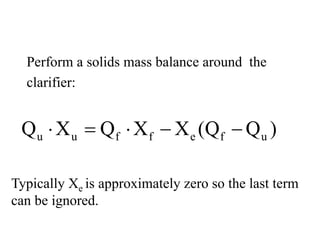

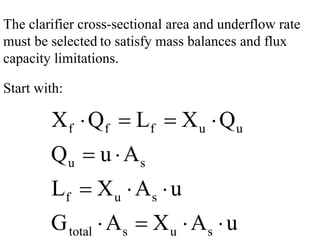

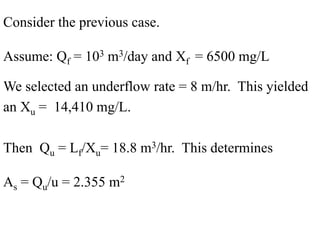

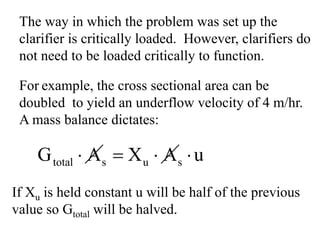

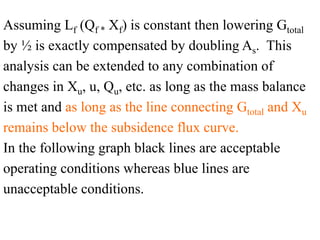

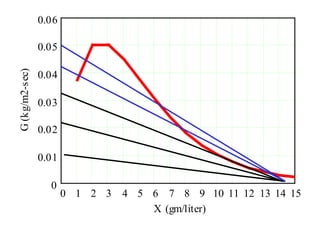

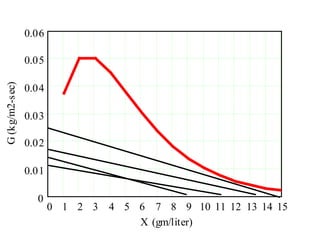

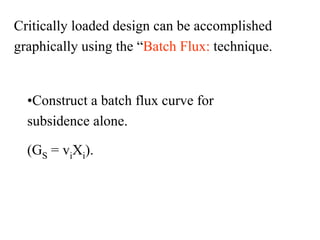

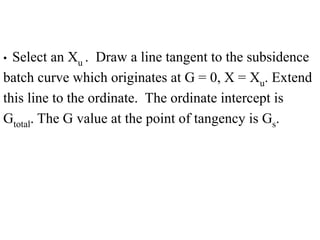

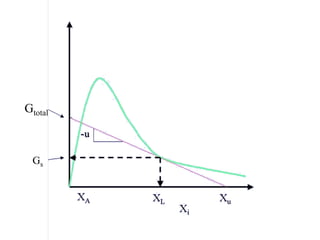

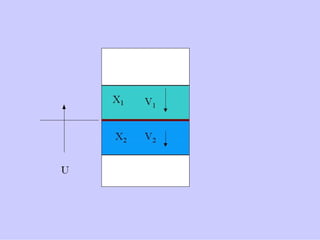

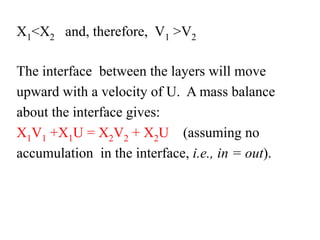

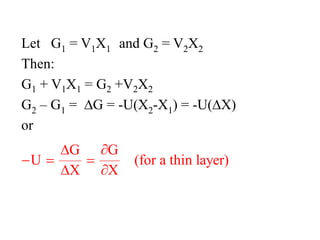

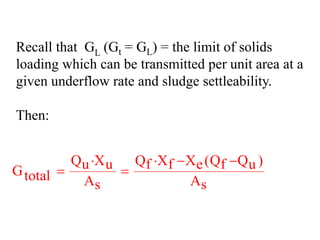

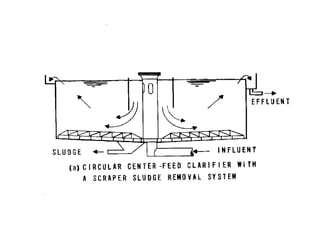

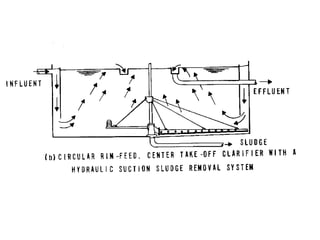

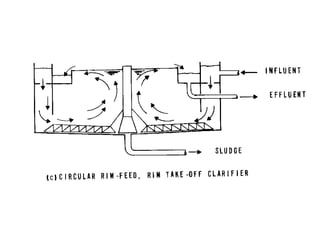

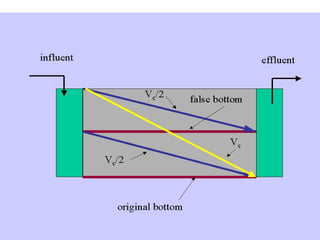

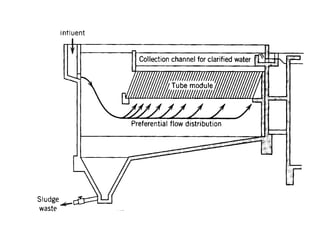

This document discusses different types and design considerations for sedimentation processes used in water and wastewater treatment to remove solids via gravity settling. It describes four types of settling (discrete, flocculent, zone, and compression) and compares design parameters for discrete and flocculent settling. The document outlines batch settling tests and analyses, including determining zone settling velocity and its relationship to solids concentration. It provides details on designing zone settling tanks, including mass balances and limiting flux analyses to size tanks and select operating parameters like underflow rate.

![ Define the following terms:

[Sedimentation, precipitation coagulation, bioxidation, etc]

Respond to the following questions:

Give a detailed account of ………………

Explain in details the process of …………..

Describe in details with examples the…………

With examples, illustrate the pharmaceutical applications of ……………](https://image.slidesharecdn.com/15-sedimentation-200630111029/85/15-sedimentation-82-320.jpg)