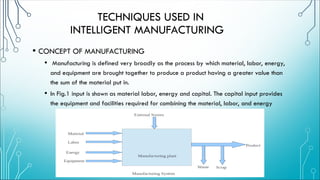

The document discusses intelligent manufacturing and its significance in future developments, highlighting the need for organizations to leverage existing knowledge and integrate systems for engineering. It outlines the role of artificial intelligence in enhancing manufacturing processes and presents steps for implementing intelligent systems to achieve self-regulating and self-controlling manufacturing operations. Additionally, it emphasizes the importance of monitoring, controlling, and intelligently designing processes to improve product quality while reducing safety risks.

![REFERENCES

• [1] G. Tecuci, Building Intelligent Agents: An Apprenticeship Multistrategy Learning., Theory,

Methodology, Tool and Case Studiem, Academic Press, 1998.

• [2] N. Jennings, M. Wooldridge, Applications of Intelligent Agents, in: N. Jennings, M.

Wooldridge (Eds.), Agent Technology. Foundations, Applications, and Markets, Springer-

Verlag 1998, pp. 3-28.

• [3] T. Smithers, On Quantitative Performance Measures of Robot Behaviour, in: Ed. L. Steels,

The Biology and Technology of Inteligent Autonomous Agents, NATO ASI Series, Series F:

Computer and Systems Sciences, Springer- Verlag 1995, Vol 144, pp. 21-52.

• [4]. Deb S.R and Chattopadhayaya,” Proc. 3rd SERC school on ‘Advanced Mfg.Tech.’ ”,

Jadavpur Calcutta, 1997.

• [5]. Kumar Surender,” Industrial Robots and CIM”, Oxford and IBH Publication Co,New Delhi.

• [6]. Kumar Surender and Jha, A.K, ”Computer Aided Design and Manufacturing”, Dhanpat

Rai and Co. Ltd., New Delhi.](https://image.slidesharecdn.com/11-240903191109-dc1581fa/85/11-Intelligent_Manufacturing_And_Services-ppt-13-320.jpg)