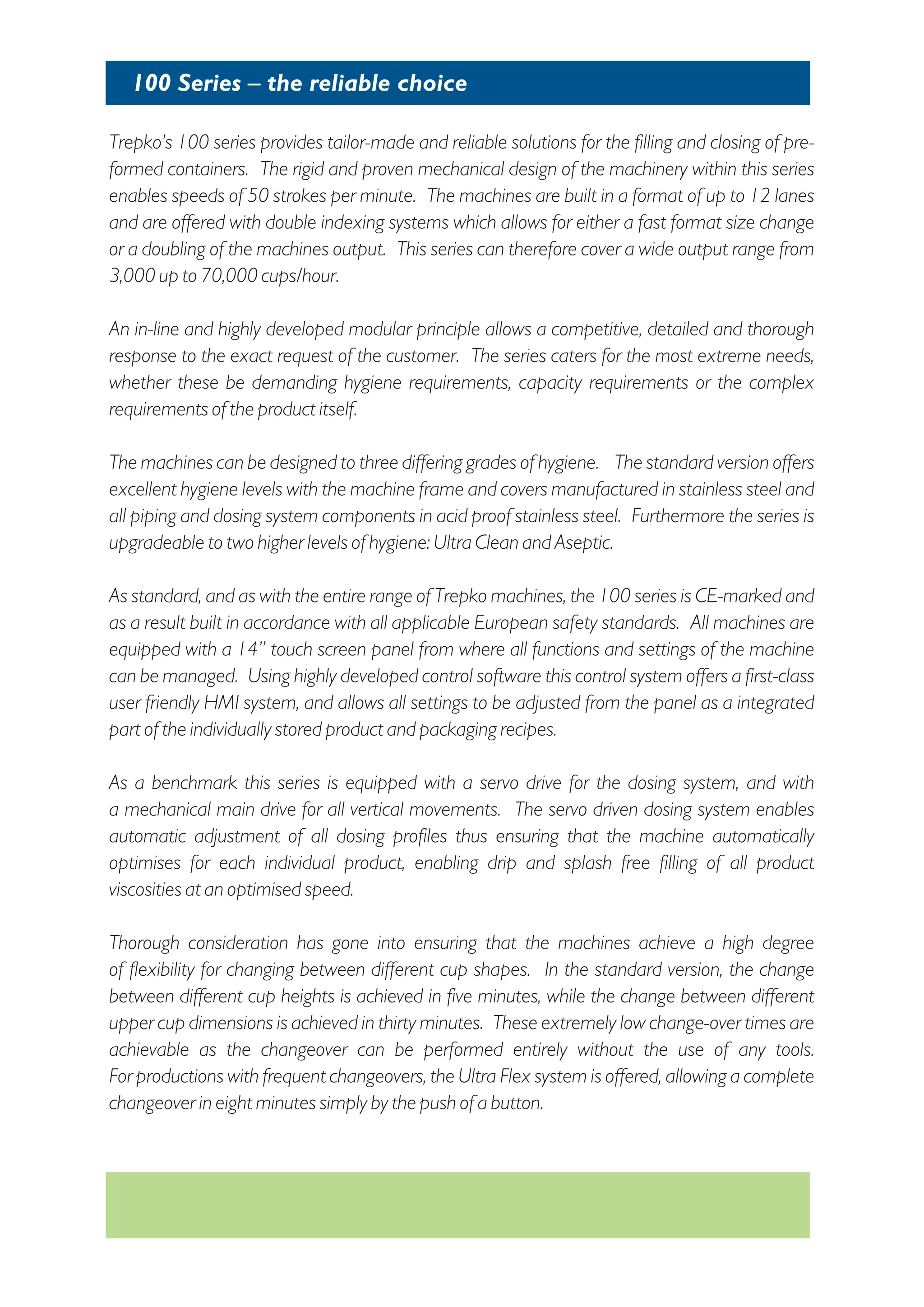

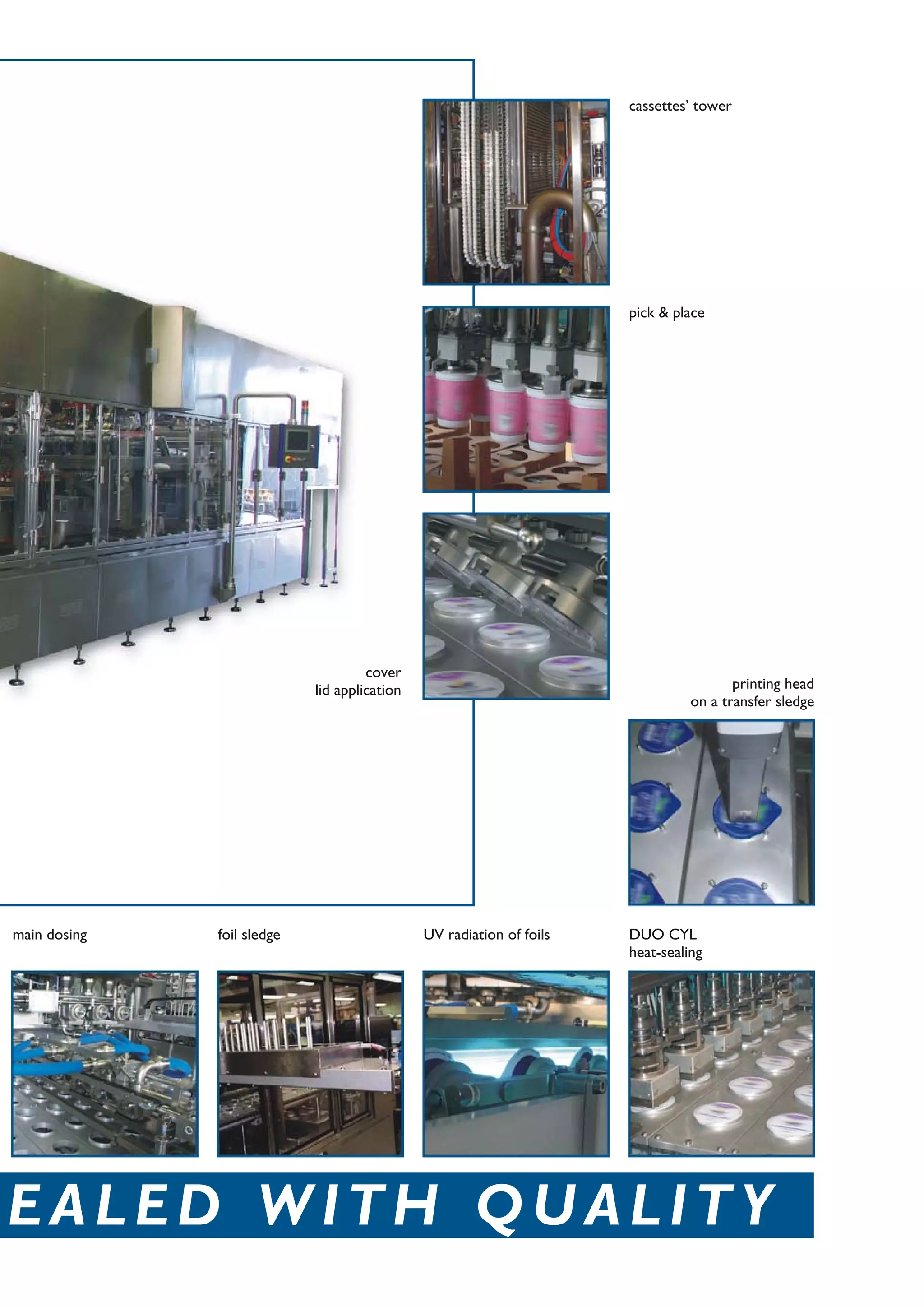

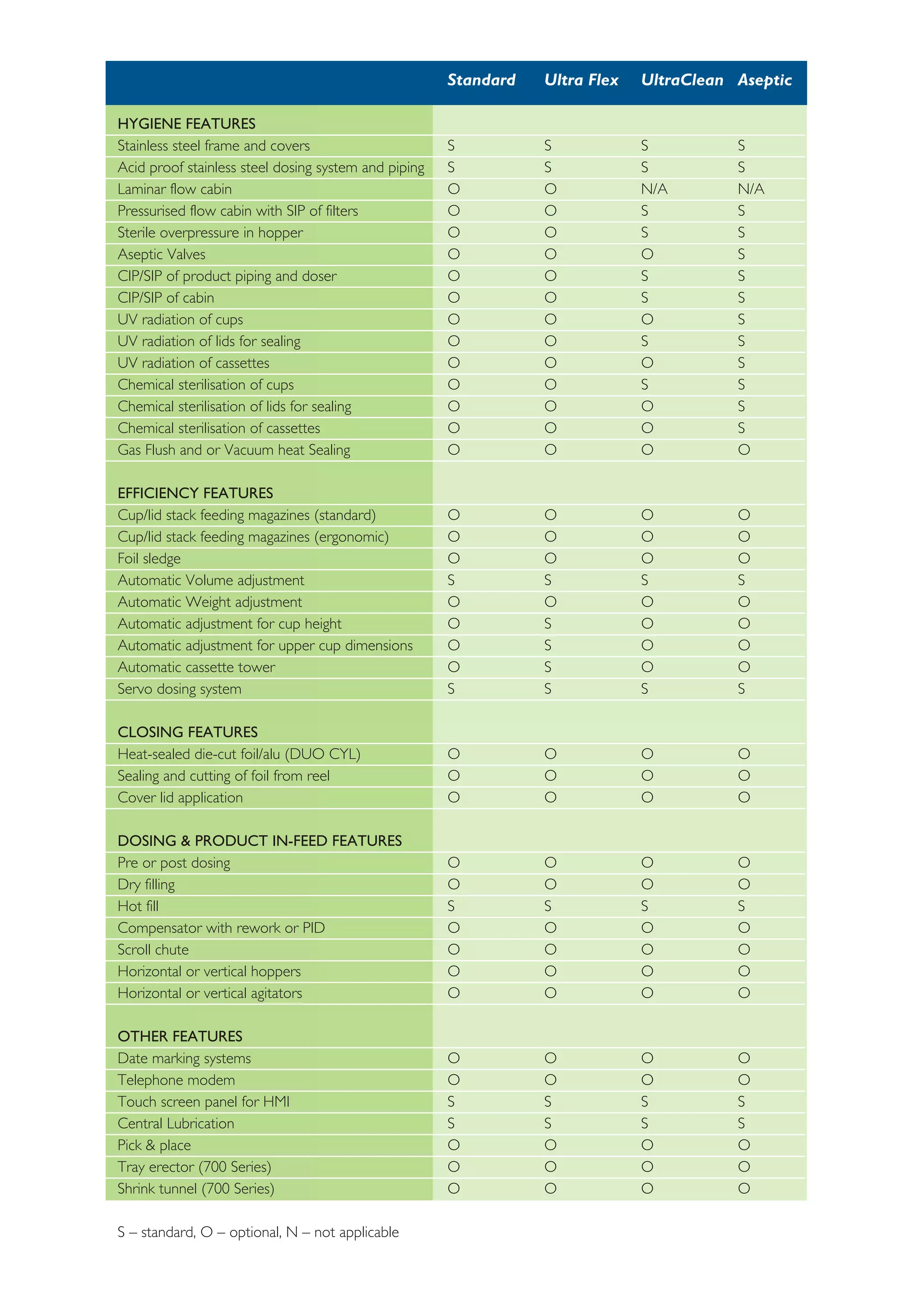

Trepko is an international company that produces filling and closing machinery. The document provides information about Trepko's 100 series machines, which are in-line machines for filling and closing pre-formed containers. The 100 series machines can be customized for different hygiene levels and capacities. They offer flexibility and reliability for production.