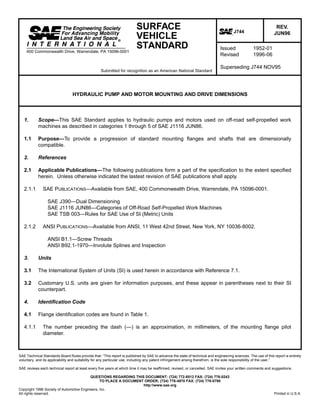

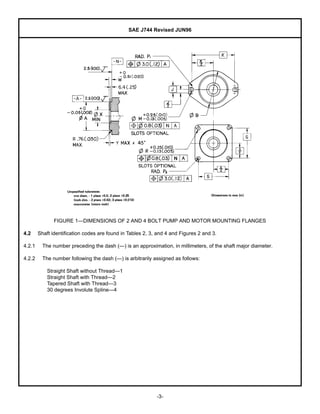

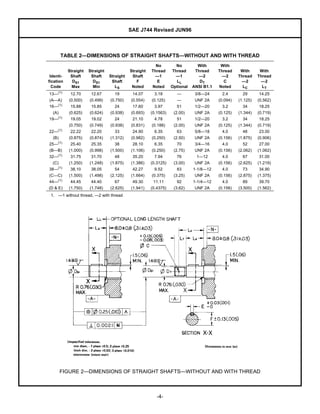

The document is an SAE standard that provides specifications for hydraulic pump and motor mounting dimensions and shaft dimensions. It includes tables that list identification codes and dimensional specifications for various flange and shaft types, including pilot diameters, bolt hole counts and sizes, thread types, and other measurements. Figures are also included to illustrate key dimensions. The standard applies to hydraulic components used on off-road equipment and provides compatible mounting and connection standards.