9 reheating furnace-48x36--lkj

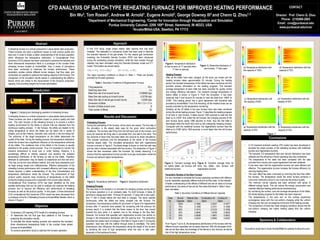

- 1. CO 0.5O2 CO2 Figure 6. Temperature Distribution Cross the Furnace Table 1.0.5O2 CO Components for Two Types Fuels CO2 Table 1. Components for Two Types Fuels (Base Case) CFD ANALYSIS OF BATCH-TYPE REHEATING FURNACE FOR IMPROVED HEATING PERFORMANCE CONTACT Bin Wu 2, Tom Roesel 1, Andrew M. Arnold 1, Eugene Arnold 3, George Downey lll3 and Chenn Q. Zhou1,2 Director: Prof. Chenn Q. Zhou 1Department of Mechanical Engineering, 2Center for Innovation through Visualization and Simulation Phone: (219)989-2665 Email: civs@purduecal.edu Purdue University Calumet, 2200 169th Street, Hammond, IN 46323, USA 3ArcelorMittal-USA, Steelton, PA 17113 www.purduecal.edu/civs/ Abstract Approach A reheating furnace is a critical component in value-added steel production. In this CFD study, single phase steady state reacting flow had been These furnaces can have a significant impact on both product quality and modeled. The realizable k-ε turbulence model had been used to describe total cost. In order to obtain a better understanding of the furnace operation the turbulent features of the gas phase. For the natural gas combustion which influences the temperature distribution, a Computational Fluid modeling, the Probability Density Function (PDF) has been introduced Dynamics (CFD) analysis has been conducted to examine the transient and during the preheating process simulation. while the heat transfer through three dimensional temperature fields in a prototype of the number three radiation has been simulated using the Discrete-Ordinates model and P-1 Figure 4. Temperature distribution reheating furnace located at ArcelorMittal. Also, a series of simulations model. The kinetics are shown below: of new furnace, at 17 seconds when Figure 5. Streamline distribution of new furnace, 1st door open (a) Temperature distribution with (b) Temperature distribution with the have been conducted to maximize the furnace performance. These 1st door is opening the capacity of 100% capacity of 75% parametric studies include different burner designs, fuel flow rates, and combustion air supplies to optimize the heating capacity of the furnace. The The major boundary conditions is shown in Table 1. These are directly Heating Process comparison of the simulation results assists in understanding the effective provided by the plant operators. After all the billets have been charged, all the doors are closed and the factors which are critical to the improvement of the furnace’s production heating process takes approximately 20 minutes. During the heating capacity, thus providing insight into furnace optimization. Table 1. Boundary Conditions of Regenerative Furnace period, the transient temperature of the billets has been monitored and this Firing sequence 40 s provides precise information on the heating progress. The transient average temperature of each billet has been recorded for quality control Introduction Switching down time 2s and energy efficiency calculation. The transient average temperature of Mass flow rate of air at each burner 0.558965 kg/s twelve billets is shown in Figure 5. From the simulation, it has been Mass flow rate cooling air at each burner 0.02795 kg/s observed that it took around 20 minutes to heat the billet from 1900F to Mass flow rate of natural gas at each burner 0.0282 kg/s (c) Temperature distribution with (d) Temperature distribution with the 2100F. This heating period has a good agreement with industrial data the capacity of 60% capacity of 50% Dimension of billets 180 × 7.5 × 11 in provided by ArcelorMittal. From this recording, all the resident times can be Number of billets at each zone 8 exactly controlled by the temperature monitoring. Total number of Billets 32 Similarly, all the 32 billets in the new furnace have also been monitored Figure.1. Charging and discharging operation of reheating furnace during the whole heating process. Figure 11 describes the heating progress of all bars in new furnace. It takes around 1000 seconds to heat the first A reheating furnace is a critical component in value-added steel production. Results and Discussion billet up to 2100F. And unlike the old furnace, the charging process of the These furnaces can have a significant impact on product quality and total new furnace alone needs 1088 seconds to finish, thus the first billet is cost . The main function of the reheating furnace is to provide a uniform Preheating Process discharged while the fourth door zone is still undergoing charging process. heating environment for the billets or blooms that are obtained from the During the preheating of the furnace, all the doors are closed. The first step in Compared with the traditional furnace, the regenerative burners heat the (e) Temperature distribution with the (f) Temperature distribution with the continuous casting process. In the furnace, the billets are heated to the the simulation is the steady state case for the given initial combustion billet up to 2100F within 1000 seconds, is much faster than the old furnace capacity of 30% capacity of 25% rolling temperature at which the billets can be rolled into a variety of conditions. The burners start firing from the left hand side of the furnace, and performance. shapes, such as the I-beams, channels, wire, rods etc. in the hot rolling mill. every 40 seconds the firing side is converted from one side to the other. The Figure 7. The uniformity of the target temperature on the billets determines the two seconds of down time has been taken into account by these simulations. quality of the steel. During the heating process, the temperature distribution This process continues until the temperature at the center of the furnace Conclusions inside the furnace has a significant influence on the temperature uniformity reaches steady state. The simulated temperature field with regenerative of the billets. The residence time of the billets in the furnace is equally burners is shown in Figure 2. The flame shape is shown on both the side view A 3-D transient turbulent reacting CFD model has been developed to essential to the quality control process. Thus it is important to monitor the and top view in planes associated with the burners. The streamline in Figure 3 simulate the whole process of the reheating furnaces with traditional transient temperature to avoid over or under heating. However, it is shows the flow movement within the furnaces. By closely observing, it is burners and regenerative burners. exceedingly difficult to directly measure and examine the transient obvious that the regenerative burners provide more gas recirculation inside the The transient 3-D temperature field and velocity distribution has been temperature distribution of the furnace as well as the billets. Therefore furnace and achieve higher temperatures. obtained and the influence of doors operating was also considered. attempts at optimization may be based on experience and trial and error. The temperature of the walls has been compared with the data This may not be the most efficient method, and may have drawbacks such Figure 5. Transient average temp Figure 6. Transient average temp for provided from industry and a good agreement has been obtained. as large energy losses and ineffectiveness. Effective optimization of the for twelve billets, old furnace with thirty two billets, new furnace with It has been seen that the regenerative burners are quite efficient and reheating furnace performance with increased efficiency and lower energy traditional burners regenerative burners effective. The regenerative burners increase the furnace efficiency by losses requires a better understanding of the flow characteristics and reducing heating time. temperature distributions inside the furnace. The achievement of high Parametric Studies of the New Furnace The door effect has been minimized by trimming the fluid flow within product quality requires close monitoring of temperatures on the billets it is very important to simulate the furnace operating conditions with different the furnace. The temperature inside the entire furnace achieves a during the heating process and is essential in the current steel industry . burner capacities, especially different fuel and air flow rates. In the interests more even distribution which in turn improves the product quality. Computational Fluid Dynamics (CFD) has been identified as the most Figure 2. Temperature distribution Figure 3. Streamline distribution The minimum burner capacity has been achieved with series of of better understanding of the effects of different fuel and air rates on furnace suitable technology that can be used to analyze and optimize the heating Charging Process performance, the series of fuel and air flow rates that listed in Table 2 have different energy inputs. This can reduce the energy consumption and process; and to improve the efficiency and performance of reheating The next step in the analysis is to simulate the charging process during which been simulated. maintain effective heating performance simultaneously. furnaces as well as the product quality. In this paper, a three-dimensional the furnace operation is in an unsteady state. For both furnaces, it takes 34 By monitoring the surface, core and average temperature of the billets, Table 2. Boundary Conditions of Different Burner Capacity (3-D) computational fluid dynamics (CFD) model has been developed from seconds to charge each billet. Of those 34 seconds, 17 pass with a door open, the whole heating progress for the billets has been observed. a prototype of the No.3 Reheating furnace at ArcelorMittal Steelton which is and 17 with it closed before the next billet is charged. The doors operate Case Burner Natural Gas Combustion Air Cooling Air The temperatures in the core and on the surface experience shown in Figure 1. continuously while the billets are being charged into the furnace. For No. Capacity (kg/s) (kg/s) (kg/s) convergence twice with the non-uniform charging while the uniform comparison, the temperature profiles (K) are shown in Figure 4 for regenerative 1 100% 0.1692 3.3537 0.1677 charging only has one convergence at the end of the heating process. Objective furnace after 17 seconds have passed. By comparing with the previous old 2 75% 0.1269 2.5151 0.1258 The comparison of these two initial charging conditions shows that the furnace result, it is evident that the flame nearer to the door has moved 3 60% 0.1015 2.0123 0.1006 non-uniform charging has higher heating speed than the uniform To develop a 3D reacting CFD model of a reheating furnace. towards the door when it is opened, due to the change in the flow field. 4 50% 0.0846 1.6769 0.0839 charging. To determine the hot flue gas flow patterns in the furnace by However, the furnace that operates with regenerative burners has almost no 5 30% 0.0508 1.0061 0.0503 analyzing the simulation results. change in the temperature distribution with the opening door. The streamline 6 25% 0.0423 0.8385 0.0425 To simulate the whole heating process and examine the transient describes the similar trend of change in flow field in Figure 4 and 5. During the Sponsors & Collaborators three dimensional temperature fields in the number three reheat operation, heat loss with the outflow through doors is inevitable. The same From Figure 7 (a) to (f), the temperature distributions of the furnace with the furnace at ArcelorMittal. phenomenon also influences the temperature along the length of the furnace different burner capacities can be easily observed. With the decrease of the by shrinking the zone of high temperature when the door is held open, fuel and air flow rates, the shrinkage of the flames is very obvious, as well as The authors would like to thank ArcelorMittal for partially funding this work. To conduct parametric study to optimize the furnace operation. especially in the traditional furnace. that of the high temperature zones.