RF Heating Meets ISPM-15 Requirements for Treating Wood Packaging

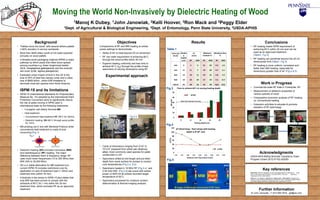

- 1. Background • “Pallets move the world” with several billions pallets (>90% wooden) in service worldwide • More than $400 billion worth of US trade exported annually on wood pallets • Untreated wood packaging material (WPM) a major pathway by which pests that infest wood spread among countries e.g. Asian longhorned beetle (ALB, Anoplophora glabripennis) and the emerald ash borer (EAB, Agrilus planipennis) • Estimated urban impact of ALB in the US is the loss of 35% of total tree canopy cover and a value loss of $669 billion , while EAB threatens to eliminate most ash species from North America. ISPM-15 and its limitations • ISPM-15 (International Standards for Phytosanitary Measure No. 15) adopted by the International Plant Protection Convention aims to significantly reduce the risk of pests moving in WPM used in international trade by the following treatments: – Fumigation with Methyl Bromide-MB – Heat treatment • Conventional Heat treatment-HT (56˚C for 30min) • Dielectric heating- DH (60˚C through wood profile for 1min) • MB phasing out in line with Montreal Protocol while conventional heat-treatment is costly & time consuming (Fig.1) • Dielectric heating (DH) includes microwave (MW) and radiofrequency (RF) heating. The major difference between them is frequency range: RF uses much lower frequencies (10 to 300 MHz) than MW (300 to 30,000 MHz) • DH is a viable alternative for MB treatment but current ISPM-15 includes restrictions over its application on size of treatment load (< 20cm) and treatment time (within 30 min) • A footnote in the annex to ISPM-15 also states that only MW has been proven to comply with the schedule of 60˚C for 1 min within the 30 min treatment time, which excludes RF as an approved treatment. Acknowledgments USDA-NIFA Methyl Bromide Transitions Grant Program (Grant 2012-51102-20208) Results Conclusions • RF heating meets ISPM requirement of achieving 60˚C within 30 min and can be used as an approved treatment (Table1, Fig 3) • RF heating can penetrate beyond the 20 cm dimensional limit (Table1, Fig 3) • RF heating is more uniform, consistent and faster than MW heating, especially for dimensions greater than 6”x6” (Fig 4 & 5) 1Manoj K Dubey, 1John Janowiak, 2Kelli Hoover, 3Ron Mack and 3Peggy Elder 1Dept. of Agricultural & Biological Engineering, 2Dept. of Entomology, Penn State University, 3USDA-APHIS Work in Progress • Commercial scale RF trials in Forestville, NY • Measurement of dielectric properties of various species of wood • Comparative economic analysis of RF heating vs. conventional heating • Extension activities to educate & promote adoption of RF technology 12 Objectives Comparisons of RF and MW heating at similar power settings to demonstrate: • Ability of RF to treat beyond 20 cm dimension • RF can meet requirement of achieving 60˚C through the wood profile within 30 min • Superior heating uniformity and less time to achieve 60˚C (t60) through the profile of test specimens of varying dimensions using RF Experimental approach • Cants of dimensions ranging from 4”x4” to 10”x10” prepared from white oak (Quercus alba)- most commonly used species for pallet construction in US • Specimens drilled at mid-length and pre-fixed depth from wood surface for probes to monitor core temperatures (Fig 2-a, 2-b) • Specimens heated in 19 MHz RF (Fig 2-c) and 2.45 GHz MW (Fig 2-d) lab ovens with similar power (3.4kW) till all probes recorded target temperature of 60˚C. • Specimens processed for moisture content determination & thermal imaging analysis Further Information Dr John Janowiak, +1-814-865-3916, jjj2@psu.edu Cant size (inch) Heatin g Depth t60 (min) Moisture Content % Moisture loss % (cm) RF MW RF MW RF MW 4x4 9 4 4 61 65 0.5 1.6 5x5 11 11 7 59 66 0.7 1.1 6x6 14 10 11 69 61 0.8 1.5 8x8 19 20 34 67 54 0.5 6.4 10x10 24 30 54 62 58 N/A N/A 0 20 40 60 80 100 120 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 ΔT(°C) Distance from Top surface (inch) ΔT (Final temp - Start temp) with heating depth in 8”x8” cant RF MW 0 10 20 30 40 50 60 9 11 14 19 24 t60(min) Heating Depth (cm) Time to achieve 60˚C at varying heating depth RF MW ISPM-15 DH Treatment Time Limit Fig.1 Fig.2-a Fig.2-dFig.2-c Fig.2-b Fig.3 Fig.4 Fig.5 Table 1 Key references FAO (2013). ISPM-15: Regulation of wood packaging material in international trade. Rome, International Plant Protection Convention-IPPC, Food and Agriculture Organization of the United Nations Strutt, A., J. A. Turner, L. Garrett, R. A. Haack, and L. Olson (2013). Evaluating the impacts of an international phytosanitory standard for wood packaging material: Global and United States implications. Forest Policy and Economics 27:54–64.