Summer

- 1. Annex 2

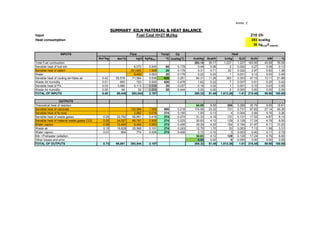

SUMMARY KILN MATERIAL & HEAT BALANCE

Input Fuel Coal H=27 MJ/kg 210 t/h

Heat consumption 293 kcal/kg

30 kgcoal/t siderite

INPUTS Flow Temp Cp Heat

3

Nm /kg Nm3/h kg/h kg/kgcal o

C kcal/kgoC kcal/kg Gcal/h kJ/kg GJ/t GJ/h kW %

Total Fuel combustion 293.18 39.17 1,227 1.227 163.95 45.58 76.09

Sensible heat of fuel kiln 6,072 0.045 60 0.178 0.49 0.06 2 0.002 0.27 0.08 0.13

Sensible heat of siderit 201,600 1.509 20 0.176 5.31 0.71 22 0.022 2.97 0.83 1.38

Water 8,400 0.063 20 0.176 0.22 0.03 1 0.001 0.12 0.03 0.06

Sensible heat of cooling air+false air 0.42 55,518 71,584 0.536 626 0.251 84.31 11.26 353 0.353 47.15 13.11 21.88

Waste Air humidity 0.01 900 723 0.005 626 0.478 1.62 0.22 7 0.007 0.91 0.25 0.42

Sensible heat of PA 0.03 3,966 5,113 0.038 20 0.237 0.18 0.02 1 0.001 0.10 0.03 0.05

Waste Air humidity 0.00 64 52 0.000 20 0.444 0.00 0.00 0 0.000 0.00 0.00 0.00

TOTAL OF INPUTS 0.45 60,448 293,544 2.197 385.32 51.48 1,613.26 1.61 215.48 59.90 100.00

OUTPUTS

Theoretical heat of reaction 64.00 8.55 268 0.268 35.79 9.95 16.61

Sensible heat of calcinate 133,594 1.000 800 0.218 174.56 23.32 731 0.731 97.62 27.14 45.30

Sensible heat of fly dust 2,562 0.019 274 0.190 1.00 0.13 4 0.004 0.56 0.16 0.26

Sensible heat of waste gases 0.25 32,782 55,851 0.418 274 0.274 31.33 4.19 131 0.131 17.52 4.87 8.13

Sensible heat of material waste gases CO2 0.25 34,027 66,797 0.500 274 0.225 30.83 4.12 129 0.129 17.24 4.79 8.00

Water vapoor 0.08 10,460 8,400 0.063 274 0.456 39.29 5.25 164 0.164 21.97 6.11 10.20

Waste air 0.15 19,828 25,566 0.191 274 0.243 12.76 1.70 53 0.053 7.13 1.98 3.31

Water vapoor 0.01 964 774 0.006 274 0.456 0.72 0.10 3 0.003 0.40 0.11 0.19

Kiln +Preheater radiation - 30.83 4.12 129 0.129 17.24 4.79 8.00

Other losses and error - 0.00 0.00 0 0.000 0.00 0.00 0.00

TOTAL OF OUTPUTS 0.73 98,061 293,544 2.197 385.32 51.48 1,613.26 1.61 215.48 59.90 100.00

- 2. 1 2 3 4 5

m 150 800 1,000 97 20

g 20 626 1,615 274 144

Temperature evolution-Efficiency 30 kg coal/t

1800

1,615

1600

1400

1200

Temperature [oC] 1,000

1000

Material

800

800 Gases

597.2289

600 626

400

274

150 144

200

20 20

0 97

1 2 3 4 5