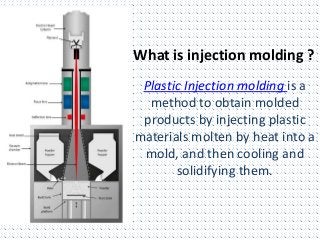

Plastic Injcetion Molding is the process of designing and manufacturing a structured mold for product to be made further.

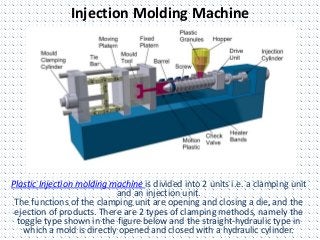

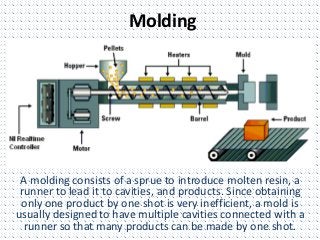

Injection molding process is of two types plastic injection molding and custom injection molding. Molding is mainly done

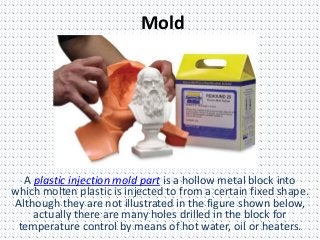

for creating a mold structure in which the mold is filled and solidified , which results in new product having same size and shape as f the mold.

For such plastic injection mold parts

visit - www.artetooling.net