Machines exam assessment sheets 10 11(joe lyster)

•

0 likes•393 views

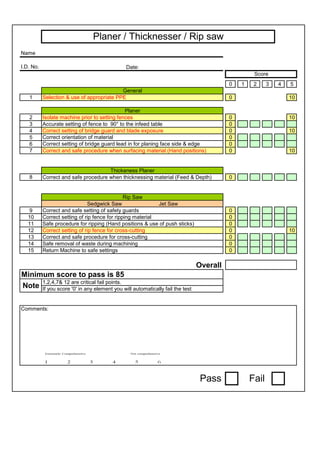

This document outlines a safety test for using woodworking machines like a planer, thickness planer, and rip saw. It lists 15 safety criteria that are scored from 0-5. To pass, the test taker must score an 85 overall and not receive a 0 on any critical criteria related to personal protective equipment, isolating machines, blade exposure settings, and cross-cutting procedures. The test is meant to ensure safe operation of these machines through demonstrating proper procedures and settings.

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

More from JOE LYSTER

More from JOE LYSTER (20)

Irish Leaving Certificate 2019 D.C.G. Revision Notes

Irish Leaving Certificate 2019 D.C.G. Revision Notes

FREE LEAVING CERTIFICATE 2017 CONSTRUCTION STUDIES QUESTION 1 NOTES

FREE LEAVING CERTIFICATE 2017 CONSTRUCTION STUDIES QUESTION 1 NOTES

Machines exam assessment sheets 10 11(joe lyster)

- 1. Planer / Thicknesser / Rip saw Name I.D. No. Date: Score 0 1 2 3 4 5 General 1 Selection & use of appropriate PPE 0 10 Planer 2 Isolate machine prior to setting fences 0 10 3 Accurate setting of fence to 90° to the infeed table 0 4 Correct setting of bridge guard and blade exposure 0 10 5 Correct orientation of material 0 6 Correct setting of bridge guard lead in for planing face side & edge 0 7 Correct and safe procedure when surfacing material (Hand positions) 0 10 Thickeness Planer 8 Correct and safe procedure when thicknessing material (Feed & Depth) 0 Rip Saw Sedgwick Saw Jet Saw 9 Correct and safe setting of safety guards 0 10 Correct setting of rip fence for ripping material 0 11 Safe procedure for ripping (Hand positions & use of push sticks) 0 12 Correct setting of rip fence for cross-cutting 0 10 13 Correct and safe procedure for cross-cutting 0 14 Safe removal of waste during machining 0 15 Return Machine to safe settings 0 Overall Minimum score to pass is 85 1,2,4,7& 12 are critical fail points. Note If you score '0' in any element you will automatically fail the test Comments: Pass Fail