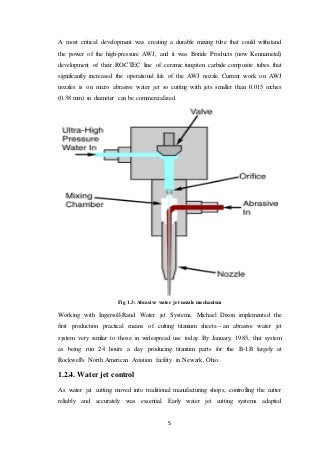

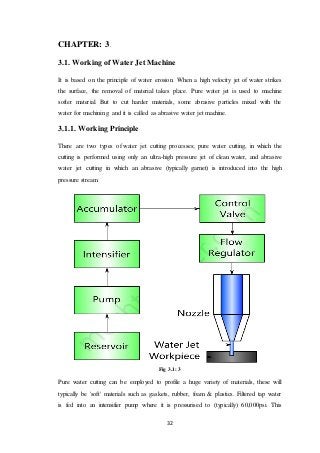

Fabrication and analysis of working model of water jet machine.Use of water jet has been in existence for over twenty years, but it is yet to reach its full potential in the construction industry.study also presents results regarding other technological operations possible to be performed with abrasive water jet.

Use of water jet has been in existence for over twenty years, but it is yet to reach its full potential in the construction industry. This study examines the role of water jet in heavy construction in general and particularly how it affects the regional contractors in the northeast. A survey was conducted among 215 civil contractors of the Northeast region of the United States and the results were documented in various categories. The paper presents aspects regarding an innovative nonconventional technology, abrasive water jet machining. The study also presents results regarding other technological operations possible to be performed with abrasive water jet.

Fabrication and analysis of working model of water jet machine..