Ever wanted how to USE a community 3D printer?

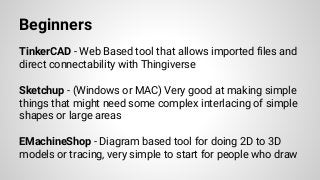

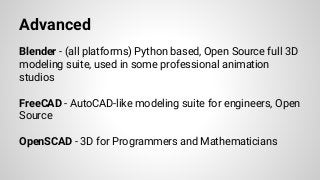

Ever wondered how to make a simple model of something?

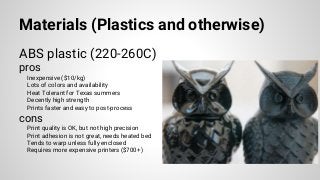

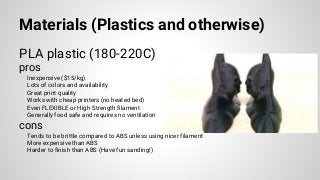

Didn't know what materials to use and what their properties are, much less all of the materials available for 3D printing?

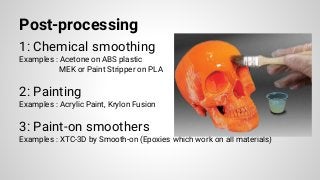

What do I do with it after I have printed it?

WE WILL ANSWER THAT!