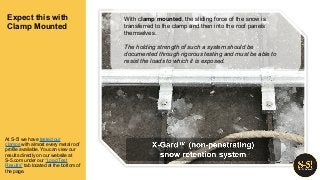

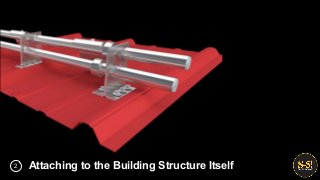

Metal roofs are a smart decision. But with metal roofs, you must consider the risk of roof top avalanches. A quality snow retention system will help you maintain your roof, avoid personal and property damage, and efficiently and safely allow snow to melt off your structure. But there are a number of methods to mount snow guard systems. What is the best way? Click through to learn the best way to mount snow retention to a metal roof!

About S-5!

S-5! has been the leading authority on metal roof attachment solutions for over 25 years. Our zero-penetration clamps attach ancillary items to standing seam metal roofs without violating roof integrity or warranties. The clamps mount snow-retention and wind-performance systems, satellite dishes, solar arrays, signs/banners, light fixtures, gas piping, stack/flue bracing, walkways, HVAC, lightning protection, equipment screens, conduit, condensate lines and more.

S-5! products are now installed on over 1.9 million metal roofs worldwide. Architects and metal roof contractors endorse S-5! as the safest engineered products and the most trusted name in the metal construction industry.

Learn more at http://www.s-5.com.

Tested. Trusted. Engineered.