Guide to vacuum casting

•

0 likes•115 views

The document provides a guide to vacuum casting using silicone molds as an alternative to 3D printing when mass production is needed. It explains that the process involves making a silicone mold from a 3D printed master model, then using the mold to cast pieces in polyurethane under vacuum conditions for strength and surface finish. Compared to 3D printing, vacuum casting allows higher volume production of parts at lower cost, enables different materials, and yields mechanically stronger pieces. The technique is suitable for small production runs of tens to hundreds of custom parts and for prototyping before moving to mass manufacturing.

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

Similar to Guide to vacuum casting

Similar to Guide to vacuum casting (20)

Kimmo K Mäkelä, VTT: 3D-tulostus: metallit ja muovit.

Kimmo K Mäkelä, VTT: 3D-tulostus: metallit ja muovit.

New eBook "An Introduction to plastic injection molding"

New eBook "An Introduction to plastic injection molding"

Engineering Guidelines to Designing Plastic Parts for Injection Molding

Engineering Guidelines to Designing Plastic Parts for Injection Molding

IRJET-Design Optimization of Mold for Dust Proof Cap

IRJET-Design Optimization of Mold for Dust Proof Cap

Posh-A high-end green mannequins manufacturer.pptx

Posh-A high-end green mannequins manufacturer.pptx

Using plastic injection molding for the manufacturing

Using plastic injection molding for the manufacturing

Recently uploaded

💉💊+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHABI}}+971581248768

+971581248768 Mtp-Kit (500MG) Prices » Dubai [(+971581248768**)] Abortion Pills For Sale In Dubai, UAE, Mifepristone and Misoprostol Tablets Available In Dubai, UAE CONTACT DR.Maya Whatsapp +971581248768 We Have Abortion Pills / Cytotec Tablets /Mifegest Kit Available in Dubai, Sharjah, Abudhabi, Ajman, Alain, Fujairah, Ras Al Khaimah, Umm Al Quwain, UAE, Buy cytotec in Dubai +971581248768''''Abortion Pills near me DUBAI | ABU DHABI|UAE. Price of Misoprostol, Cytotec” +971581248768' Dr.DEEM ''BUY ABORTION PILLS MIFEGEST KIT, MISOPROTONE, CYTOTEC PILLS IN DUBAI, ABU DHABI,UAE'' Contact me now via What's App…… abortion Pills Cytotec also available Oman Qatar Doha Saudi Arabia Bahrain Above all, Cytotec Abortion Pills are Available In Dubai / UAE, you will be very happy to do abortion in Dubai we are providing cytotec 200mg abortion pill in Dubai, UAE. Medication abortion offers an alternative to Surgical Abortion for women in the early weeks of pregnancy. We only offer abortion pills from 1 week-6 Months. We then advise you to use surgery if its beyond 6 months. Our Abu Dhabi, Ajman, Al Ain, Dubai, Fujairah, Ras Al Khaimah (RAK), Sharjah, Umm Al Quwain (UAQ) United Arab Emirates Abortion Clinic provides the safest and most advanced techniques for providing non-surgical, medical and surgical abortion methods for early through late second trimester, including the Abortion By Pill Procedure (RU 486, Mifeprex, Mifepristone, early options French Abortion Pill), Tamoxifen, Methotrexate and Cytotec (Misoprostol). The Abu Dhabi, United Arab Emirates Abortion Clinic performs Same Day Abortion Procedure using medications that are taken on the first day of the office visit and will cause the abortion to occur generally within 4 to 6 hours (as early as 30 minutes) for patients who are 3 to 12 weeks pregnant. When Mifepristone and Misoprostol are used, 50% of patients complete in 4 to 6 hours; 75% to 80% in 12 hours; and 90% in 24 hours. We use a regimen that allows for completion without the need for surgery 99% of the time. All advanced second trimester and late term pregnancies at our Tampa clinic (17 to 24 weeks or greater) can be completed within 24 hours or less 99% of the time without the need surgery. The procedure is completed with minimal to no complications. Our Women's Health Center located in Abu Dhabi, United Arab Emirates, uses the latest medications for medical abortions (RU-486, Mifeprex, Mifegyne, Mifepristone, early options French abortion pill), Methotrexate and Cytotec (Misoprostol). The safety standards of our Abu Dhabi, United Arab Emirates Abortion Doctors remain unparalleled. They consistently maintain the lowest complication rates throughout the nation. Our Physicians and staff are always available to answer questions and care for women in one of the most difficult times in their lives. The decision to have an abortion at the Abortion Cl+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...?#DUbAI#??##{{(☎️+971_581248768%)**%*]'#abortion pills for sale in dubai@

Recently uploaded (20)

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

Strategies for Unlocking Knowledge Management in Microsoft 365 in the Copilot...

Strategies for Unlocking Knowledge Management in Microsoft 365 in the Copilot...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Apidays Singapore 2024 - Scalable LLM APIs for AI and Generative AI Applicati...

Apidays Singapore 2024 - Scalable LLM APIs for AI and Generative AI Applicati...

Axa Assurance Maroc - Insurer Innovation Award 2024

Axa Assurance Maroc - Insurer Innovation Award 2024

2024: Domino Containers - The Next Step. News from the Domino Container commu...

2024: Domino Containers - The Next Step. News from the Domino Container commu...

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

AWS Community Day CPH - Three problems of Terraform

AWS Community Day CPH - Three problems of Terraform

Automating Google Workspace (GWS) & more with Apps Script

Automating Google Workspace (GWS) & more with Apps Script

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

A Beginners Guide to Building a RAG App Using Open Source Milvus

A Beginners Guide to Building a RAG App Using Open Source Milvus

Exploring the Future Potential of AI-Enabled Smartphone Processors

Exploring the Future Potential of AI-Enabled Smartphone Processors

Guide to vacuum casting

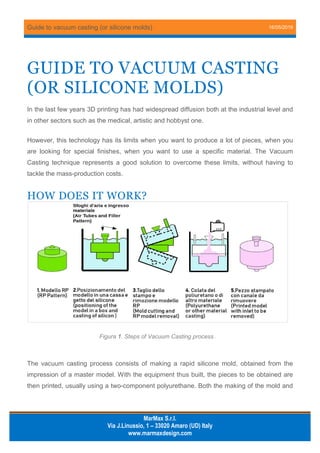

- 1. Guide to vacuum casting (or silicone molds) 16/05/2019 MarMax S.r.l. Via J.Linussio, 1 – 33020 Amaro (UD) Italy www.marmaxdesign.com GUIDE TO VACUUM CASTING (OR SILICONE MOLDS) In the last few years 3D printing has had widespread diffusion both at the industrial level and in other sectors such as the medical, artistic and hobbyst one. However, this technology has its limits when you want to produce a lot of pieces, when you are looking for special finishes, when you want to use a specific material. The Vacuum Casting technique represents a good solution to overcome these limits, without having to tackle the mass-production costs. HOW DOES IT WORK? The vacuum casting process consists of making a rapid silicone mold, obtained from the impression of a master model. With the equipment thus built, the pieces to be obtained are then printed, usually using a two-component polyurethane. Both the making of the mold and Figura 1. Steps of Vacuum Casting process .

- 2. Guide to vacuum casting (or silicone molds) 16/05/2019 MarMax S.r.l. Via J.Linussio, 1 – 33020 Amaro (UD) Italy www.marmaxdesign.com Pagina 2 the casting of the polyurethane must be carried out under vacuum, to guarantee the excellent characteristics of mechanical strength and surface finish typical of this technology. Usually the master is obtained through 3D printing, possibly with a technique that provides a good surface finish, as stereolithography, and the casting polyurethane is chosen according to the characteristics to be obtained for the piece (mechanical strength, transparency, color, elasticity, weight, conductivity, flame resistance, etc.). Alternatively, the master can also be realized with other technologies (numerical control, handmade modeling) and it can also be made up by a detail commercially available, an old piece out of production or a work of art. Even the casting material can be of different types: epoxy resins, waxes, ceramic and composite materials can be used instead of polyurethane. WHAT ARE THE BENEFITS? The vacuum casting represents an intermediate solution between the production of a single model made in 3D printing and a series produced with injection molding or other mass production solutions. In general, compared to 3d printing, the vacuum casting: it is more convenient economically if there are several pieces to be made; allows the use of a wider range of materials; provides anisotropic and mechanically more performing pieces; supplies pieces with more controllable finishes and similar to the pieces produced with standard technologies; is able to manage features that are difficult to be obtained with 3D printing, like transparency, elasticity, color gradation;

- 3. Guide to vacuum casting (or silicone molds) 16/05/2019 MarMax S.r.l. Via J.Linussio, 1 – 33020 Amaro (UD) Italy www.marmaxdesign.com Pagina 3 Picture 2: Transparent, elastomeric, translucent colored items, obtained from silicone molds. can be used to assemble different materials, for example to incorporate bushings, pins, different types of inserts, electronic boards, but also to overmold two different plastic materials or a plastic and an elastomer. Picture 3: Co-molded pieces: white polyurethane on a threaded steel pin, colored elastomer on black rigid polyurethane, polyurethane on a bronze threaded bush. Instead, compared to mass production solutions, such as injection molding: is convenient if there are few pieces to make; allows the management of some undercuts, without the use of inserts; accepts, within certain limits, the presence of variable thicknesses without giving rise to important distortion to the pieces.

- 4. Guide to vacuum casting (or silicone molds) 16/05/2019 MarMax S.r.l. Via J.Linussio, 1 – 33020 Amaro (UD) Italy www.marmaxdesign.com Pagina 4 HOW MUCH DOES IT COST TO BUILD A PRE- SERIES? It is obviously difficult to give cost indications valid for every model but, in general, it can be said that the cost of a mold can vary between 200 and 1000 €, while the cost of the single piece can vary between 10 and 100 €, moving from smaller and simpler pieces to larger and geometrically complex ones. Considering that each mold can print about 20 times, the unitary cost, including equipment, can vary between 20 and 150 €. These costs can be reduced if multi-impression molds can be produces or cheaper materials can be cast. WHEN DOES THIS SOLUTION MAKE SENSE? These technical and economic features make silicone molds the ideal solution for different situations: for small series productions for niche articles (from tens to hundreds of pieces); to manufacture custom products, with different sizes, difficult to manage with an injection-mold; for the intermediary development of a project, when all the details are not defined yet but you want to start testing a small series of the final product in the field; for the advanced development of a project, when you have a product that is basically ready for the market but that you are not able to produce in large numbers (because of costs and time to set up the equipment, because the market is very variable both in terms of consumer demand and in terms of available components); to copy and replicate objects for which the CAD model is not available, that can be craft models, artistic works, natural objects; to make spare parts for items out of production, that is believed to have market numbers that are not compatible with mass production. In the latter two cases, the silicone molds solution is usually a cheaper alternative, compared to the reverse engineering process that includes: scan, data-processing, CAD re-modeling, which can be very expensive and not always necessary.