Compliance Legal Framework Review snapshot

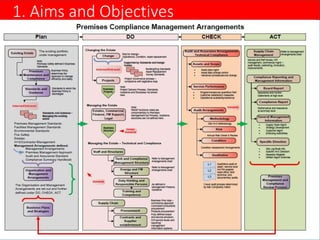

- 1. 1. Aims and Objectives IN STRICTEST CONFIDENCE 1

- 3. Compliance Simplified 3 Compliance Assurance : Asset Data Standards Process Mgmt. Persons Design Guides : influence initial compliance and at refurbishment Audit: Quantitive Perf Tech Qualitative Mgmt. Groups Duties Understood : Legislative Reqs Arrangements : Contracts – compliance Performance Reqs Resource Database Reporting

- 4. General H+S reqs Specific Legislation Business Mandatory Reqs Business Interpreted Stds Overall Standards Compliance Handbook TFM Contract Specialists Contracts General Performance KPI Quantitive Qualitative Audits Software/ Database Process Handbook Audit Handbook Capital/ LCR delivered Compliance Management Actions Reporting Menu Management and Board Reports New/Refurb Design Guidance Management Arrangements

- 5. The Compliance Approach 5 Compliance Reports Legal Framework Applicability test to Business Policy, Standards, Guidance Supply Chain Procured Test and Certification Compliance Database Industry Stds Current/Future Operating Conditions Bus. Standards Draft defined Suite of P+S, Guidance Comprehensive Design Guides TFM Contract Specialist Suppliers Assets and Frequency maintained Performance and Certification Risk Based Management Dynamic Supplier Mgmt. Programme KPI Mgmt. Procurement and Process Gaps reviewed and closed Structure, Database and Audit Function Recommendations as part of Compliance Review Feedback Loop Process Review and refinement as function of Compliance Forum KEY - Activity Supporting Process Key Process Step Key Decision Legislation and ACOP Review Board Reports Assurance Statement BRE Exercise Overall Review by Business – Determination of Operating Suite Audit Function Data/ System Audits Technical Audit Compliance Forum Independent Compliance Review Compliance Summaries Compliance Process

- 6. The Standards and Guidance Delivery Approach 6 Menu of reqd P+S Data Gather P+S, Guidance developed Stakeholder Approval Publication Training Industry Stds Current/Future Operating Conditions Bus. Existing Standards Draft defined Suite of P+S, Guidance Comprehensive Design Guides Impact Statement Responsibility Matrix Ownership/ Version and Date controls Database and Protection Guides and Templates Process Mapping KEY - Activity Supporting Process Key Process Step Legislation and ACOP Review BRE Exercise Review In use Review Change and Date Triggers Bus. Reqd Operating Standards Guiding Principles Legislative / Process Updates Business SME Engaged Supply Chain Engaged

- 7. FireElectricalMechanical EnvironmentalBuilding 1. Earthing Systems 2. Electrical Installation Inspection 3. Emergency Lights High Voltage Installations 4. Lightning Protection Systems 5. PCB’s – (old switchgear) 6. Portable Appliance Testing 1. Aircon – F Gas 2. Biomass Boilers 3. Cooling Towers 4. Dock Levellers 5. Gas Installation + Appliances 6. Legionella and Water Hygiene 7. LEV Systems 8. Lifting Equipment (scissor lifts, lifting beams etc) 9. Lifts 10. LPG – Fixed Systems 11. Microwave Ovens 12. Power operated shutter, sectional and rapid roll doors 13. Pressure Systems and Vessels 14. Traffic Barriers, Gates, Hydraulic Ramps 1. Access Equipment- Fall arrest etc 2. Asbestos Management 3. Eye Bolts 4. Fixed Ladders and Gantries 5. Glazing Safety 6. Radiation Safety – naturally occurring radiation 7. Window Cradles 1. Control of Substances Hazardous to Health (COSHH) Regs 2002 2. Display Energy Certificate 3. Discharge Consents 4. Fuel Facilities and Adblue 5. Grease Traps and Dosing Systems 6. Hazardous Waste 7. Invasive Weeds (principally Japanese Knotweed) 8. Oil Interceptors 9. Oil Storage (>200 litres) 10. Oil Storage (Drums < 200l, Intermediate bulk containers <1000l) 11. Vehicle Washing and Cleaning 1. ASD Systems (very early smoke detection) 2. Fire Dampers 3. Fire Detection and Alarm Systems 4. Fire Doors 5. Fire Fighting Equipment 6. Fire Risk Assessment 7. Gas Extinguishing Systems 8. Hydrants and Fire Risers 9. Pocket Vibrating Fire Warning Systems 10. Refuge Areas and Evac. Chairs 11. Smoke Control Systems and Vents 12. Sprinkler Systems

- 8. L1 -High Risk , High Impact – eg : Asbestos ,Legionella, Lifts, Electrical L2 – Medium Risk, eg : gas , equipment, L3 - Lower Risk , eg glazing safety, radiation safety Why ? – certain assets and activities warrant additional audit – risk, severity, likelihood and complexity of delivery determine the targets. Who ? – balance of internal and external resource structured through eg HV Mgmt. Team, Compliance Forum, What ? – quantitive, qualitative, methodology, training (int. and ext.) recording, reporting , benchmark compliance. Compliance Deep Audit Volatile, subject to multiple influences, based on 3rd party assessed risk, complex layered delivery with high risk of supply chain failure – DEEP AUDIT NEEDED Less complex delivery requirements, more fully defined, less risk based and less likelihood of process failure by supply chain – STD Quantitive/ Qualitative Audit suffices? Proposed Graduated Approach Typically routine delivery requirements , generic delivery through supply chain/ PiC, low likelihood of process failure. - – STD Quantitive/ Qualitative Audit suffices less frequently.

- 9. Heading Asset Element Severity Likelihood Complexity Score/ Indicator L1 L2 L3 Electrical Earthing Systems 5 3 1 9 y Electrical Electrical Installation Inspection 5 3 4 12 y Electrical Emergency Lights 2 2 1 5 y Electrical High Voltage Installations 5 3 5 13 y Electrical Lightning Protection 5 1 1 7 y Electrical PCB Old Switchgear 2 1 1 4 y Electrical Portable Appliance Testing 2 1 1 4 y Mechanical Aircon - F Gas 1 2 1 4 y Mechanical Biomass Boilers 2 1 1 4 y Mechanical Cooling Towers 5 4 5 14 y Mechanical Dock Levellers 2 1 1 4 y Audit LevelAudit Level Scoring Audit Level Scoring