VPG Load Cell Mounting

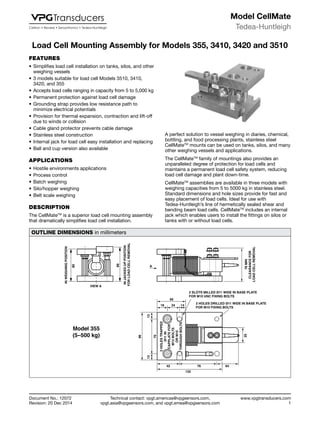

- 1. Technical contact: vpgt.americas@vpgsensors.com, vpgt.asia@vpgsensors.com, and vpgt.emea@vpgsensors.com Tedea-Huntleigh www.vpgtransducers.com 1 Model CellMate Document No.: 12072 Revision: 20 Dec 2014 Load Cell Mounting Assembly for Models 355, 3410, 3420 and 3510Load Cell Mounting Assembly for Models 355, 3410, 3420 and 3510 A perfect solution to vessel weighing in diaries, chemical, bottling, and food processing plants, stainless steel CellMateTM mounts can be used on tanks, silos, and many other weighing vessels and applications. The CellMateTM family of mountings also provides an unparalleled degree of protection for load cells and maintains a permanent load cell safety system, reducing load cell damage and plant down-time. CellMateTM assemblies are available in three models with weighing capacities from 5 to 5000 kg in stainless steel. Standard dimensions and hole sizes provide for fast and easy placement of load cells. Ideal for use with Tedea-Huntleigh’s line of hermetically sealed shear and bending beam load cells. CellMateTM includes an internal jack which enables users to install the fittings on silos or tanks with or without load cells. OUTLINE DIMENSIONS in millimeters 80 VIEW A A INJACKEDUPPOSITION FORLOADCELLREMOVAL 86 2 SLOTS MILLED Ø11 WIDE IN BASE PLATE FOR M10 UNC FIXING BOLTS 2 HOLES DRILLED Ø11 WIDE IN BASE PLATE FOR M10 FIXING BOLTS 56 18 1424 96 1313 70 2HOLESTRAPPED Ø11IN CAPPLATEFOR M12BOLTS ORM10 THROUGHBOLTS 42 76 64 132 25 INWEIGHINGPOSITION Model 355 (5–500 kg) 78MIN CLEARANCEFOR LOADCELLREMOVAL FEATURES • Simplifies load cell installation on tanks, silos, and other weighing vessels • 3 models suitable for load cell Models 3510, 3410, 3420, and 355 • Accepts load cells ranging in capacity from 5 to 5,000 kg • Permanent protection against load cell damage • Grounding strap provides low resistance path to minimize electrical potentials • Provision for thermal expansion, contraction and lift-off due to winds or collision • Cable gland protector prevents cable damage • Stainless steel construction • Internal jack for load cell easy installation and replacing • Ball and cup version also available APPLICATIONS • Hostile environments applications • Process control • Batch weighing • Silo/hopper weighing • Belt scale weighing DESCRIPTION The CellMateTM is a superior load cell mounting assembly that dramatically simplifies load cell installation.

- 2. Technical contact: vpgt.americas@vpgsensors.com, vpgt.asia@vpgsensors.com, and vpgt.emea@vpgsensors.com Tedea-Huntleigh www.vpgtransducers.com 2 Model CellMate Document No.: 12072 Revision: 20 Dec 2014 Load Cell Mounting Assembly for Models 355, 3410, 3420 and 3510 OUTLINE DIMENSIONS in millimeters JACKEDUPFOR LOADCELLREMOVAL 108 100 VIEW A 106MIN CLEARANCEFOR 3410LOAD CELLREMOVAL INWEIGHINGPOSITION A 3410 3510 111MIN CLEARANCEFOR 3510LOADCELLREMOVAL 2 X 3/4" - 10 HOLES IN CAP PLATE FOR 3/4" UNC BOLTS OR 5/8" THROUGH BOLTS 2 SLOTS MILLED 0.78" WIDE IN BASE PLATE FOR 3/4" FIXING BOLTS 2 x 0.78" DIA: THRU HOLES IN BASE PLATE FOR 3/4" FIXING BOLTS 3015 max. 81 110 2020 70 2015 130 165 30 Model 3410/3411 (1,000–4,000 lbs) (250–2,000 kg) Model 3510 (300–2,000 kg) 135 INWEIGHINGPOSITION VIEW A 3420 3510 Model 3420/3421 (5,000–10,000 lbs) Model 3510 (3000 and 5,000 kg) A 2 SLOTS MILLED 0.78" WIDE IN BASE PLATE FOR 3/4" FIXING BOLTS 2 HOLES DRILLED 0.78" BASE PLATE FOR 3/4" FIXING BOLTS 3520 91 36 153 31.531.5 90 16220 34 216 47 40 140 JACKEDUPFOR LOADCELLREMOVAL 159MIN CLEARANCEFOR 3420LOAD CELLREMOVAL 143

- 3. Vishay Precision Group, Inc. www.vpgsensors.com 1 Legal Disclaimer Notice Document No.: 63999 Revision: 15-Jul-2014 Disclaimer ALL PRODUCTS, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE. Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “VPG”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein or in any other disclosure relating to any product. The product specifications do not expand or otherwise modify VPG’s terms and conditions of purchase, including but not limited to, the warranty expressed therein. VPG makes no warranty, representation or guarantee other than as set forth in the terms and conditions of purchase. To the maximum extent permitted by applicable law, VPG disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Information provided in datasheets and/or specifications may vary from actual results in different applications and performance may vary over time. Statements regarding the suitability of products for certain types of applications are based on VPG’s knowledge of typical requirements that are often placed on VPG products. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. You should ensure you have the current version of the relevant information by contacting VPG prior to performing installation or use of the product, such as on our website at vpgsensors.com. No license, express, implied, or otherwise, to any intellectual property rights is granted by this document, or by any conduct of VPG. The products shown herein are not designed for use in life-saving or life-sustaining applications unless otherwise expressly indicated. Customers using or selling VPG products not expressly indicated for use in such applications do so entirely at their own risk and agree to fully indemnify VPG for any damages arising or resulting from such use or sale. Please contact authorized VPG personnel to obtain written terms and conditions regarding products designed for such applications. Product names and markings noted herein may be trademarks of their respective owners. Copyright Vishay Precision Group, Inc., 2014. All rights reserved. Disclaimer Legal Disclaimer Notice