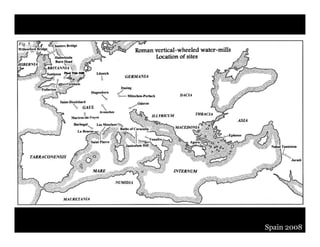

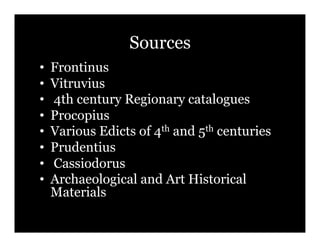

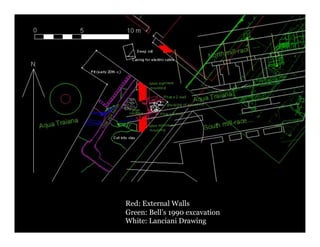

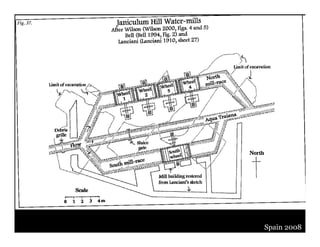

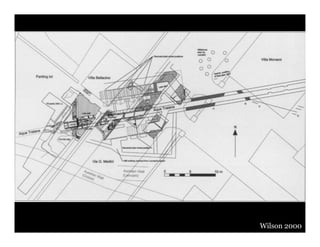

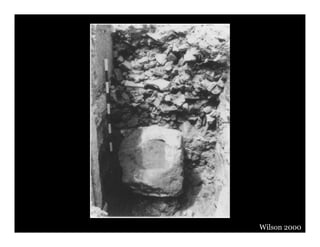

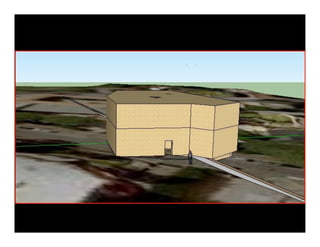

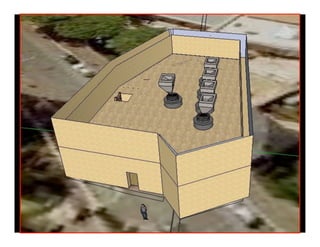

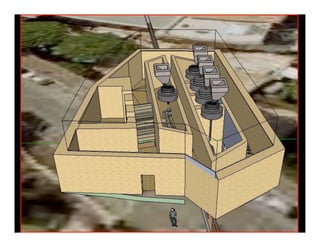

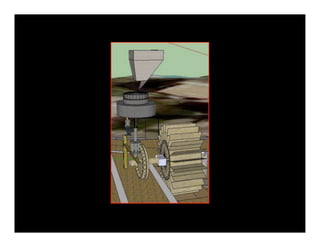

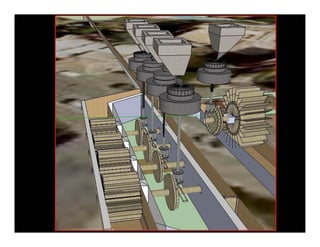

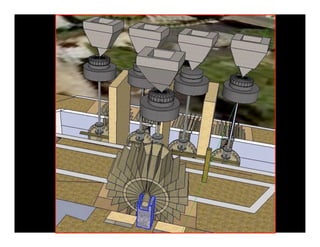

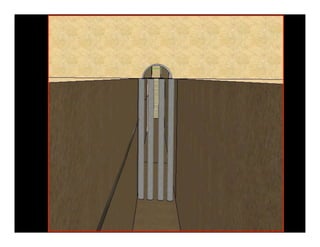

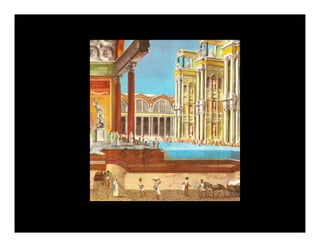

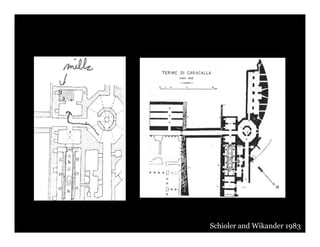

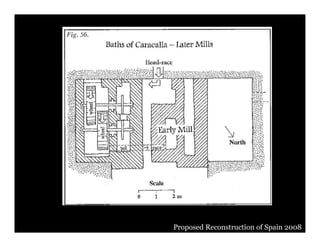

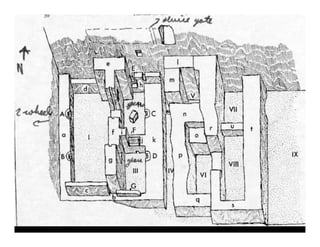

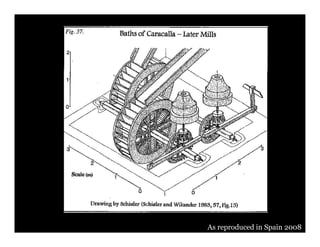

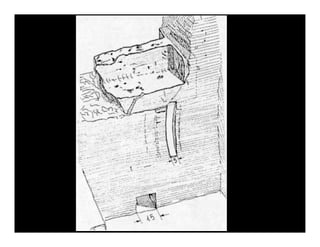

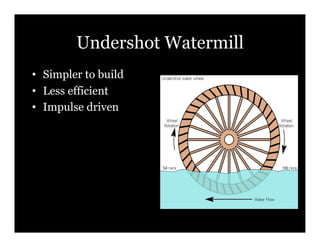

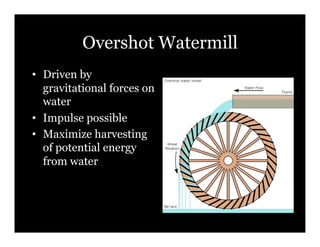

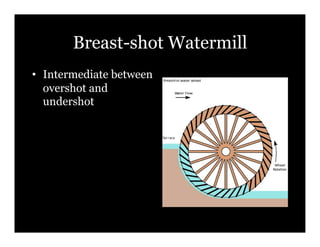

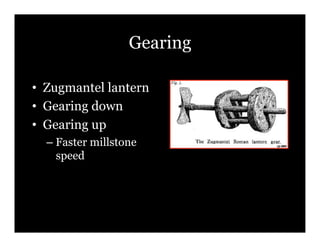

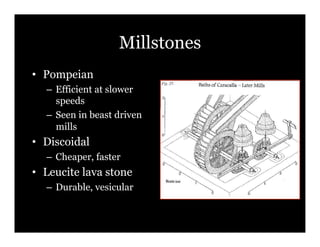

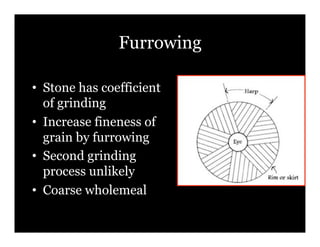

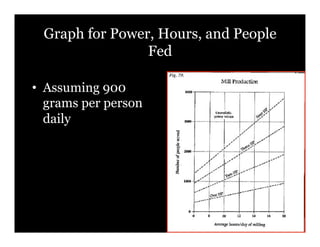

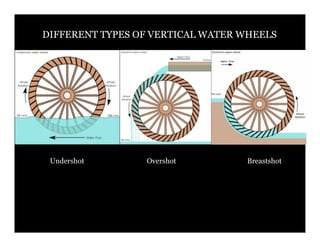

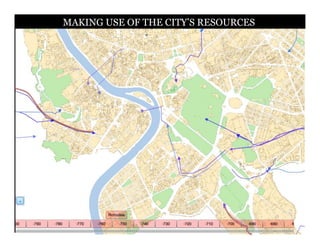

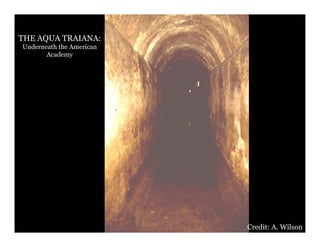

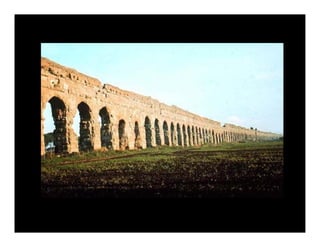

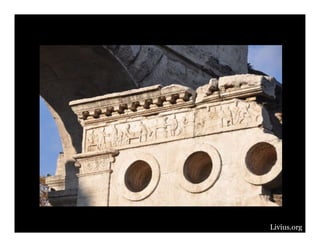

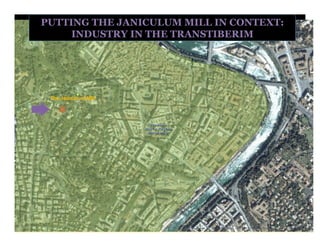

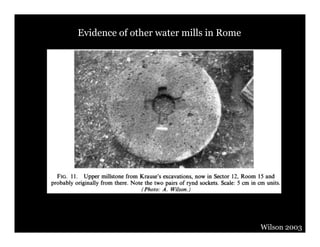

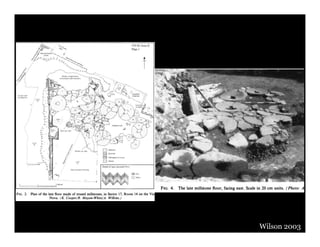

The document provides an overview of the water mills in Rome, detailing their architecture, technology, and economic impact. It discusses different types of water mills, their construction efficiency, and production output, along with historical sources that inform the study. Additionally, it analyzes power generation calculations for millstones and places the Janiculum mill within the broader context of industrial activity in Rome.