More Related Content

Similar to 22144 Lafayette East v121.PDF

Similar to 22144 Lafayette East v121.PDF (20)

22144 Lafayette East v121.PDF

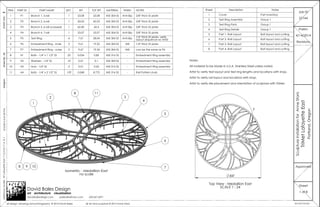

- 1. Isometric - Medallion East

no scale

32

4

5

1

8

7

6

8 9 10

11

84"

F

Top View - Medallion East

SCALE 1 : 24

Notes:

All material to be Made in U.S.A. Stainless Steel unless noted.

Artist to verify text layout and text ring lengths and locations with shop.

Artist to verify rail layout and locations with shop.

Artist to verify site placement and orientation of sculpture with TriMet.

ITEM PART ID PART NAME QTY. WT TOT WT MATERIAL FINISH NOTES

1 P1 Branch 1, 5-rail 1 53.08 53.08 AISI 304 SS Anti-Slip 3/8" thick SS plate

2 P2 Branch 2, 6-rail 1 60.03 60.03 AISI 304 SS Anti-Slip 3/8" thick SS plate

3 P3 Branch 3, 6-rail (crossed) 1 60.40 60.4 AISI 304 SS Anti-Slip 3/8" thick SS plate

4 P4 Branch 4, 7-rail 1 53.07 53.07 AISI 304 SS Anti-Slip 3/8" thick SS plate

5 P5 Text Ring 4 7.01 28.04 AISI 304 SS Anti-Slip

1/4" thick SS plate, verify

layout sequence w/ Artist

6 P6 Embedment Ring - inner 2 9.61 19.22 AISI 304 SS Mill 1/4" thick SS plate

7 P7 Embedment Ring - outer 2 9.67 19.34 AISI 304 SS Mill can be the same as P6

8 H1 Bolts - 1/4" x 1 1/2" SS 25 0.034 0.85 AISI 316 SS - Embedment Ring assembly

9 H2 Washers - 1/4" SS 10 0.01 0.1 AISI 304 SS - Embedment Ring assembly

10 H3 Nuts - 1/4" SS 5 0.01 0.05 AISI 316 SS - Embedment Ring assembly

11 H4 Bolts - 1/4" x 2 1/2" SS 129 0.068 8.772 AISI 316 SS - Rail Pattern studs

Sheet Description Notes

1 Cover Part Inventory

2 Text Ring Assembly Group 1

3 Text Ring Parts Group 1

4 Text Ring Details Group 1

5 Part 1- Rail Layout Bolt layout and cutting

6 Part 2- Rail Layout Bolt layout and cutting

7 Part 3- Rail Layout Bolt layout and cutting

8 Part 4- Rail Layout Bolt layout and cutting

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

all design, drawings and photography © 2014 David Bales

Bsheetsize:referencemodel:AFLafayetteEast11.2.33.0.11.412.14/3/20145:41:09PM

DO NOT SCALE

Sheet

1 of 8

all art and sculpture © 2014 Anne Storrs

- 2. 10.77

(typ)

A

C

11

Assembly Bottom View

SCALE 1 : 12

1/4 x 1 1/2" SS embedment studs

w/ equal spacing, (5) per ring section

1/4 x 1 1/2" SS assembly bolts with

nuts and washers, weld optional per shop

1/4" x 2" SS vertical embedment ring

1/4" x 1 1/2" SS text ring, etched

on reverse (bottom view)

1/2 - 3

1/2 - 3

typ all rings

Assembly Front View

SCALE 1 : 12

DETAIL A

SCALE 1 : 2

1/4" x 1 1/2" SS text ring, etched

on reverse (bottom view)

1/4" x 2" SS vertical embedment ring

1/4 x 1 1/2" SS embedment

studs, spacing as noted

1/8

1/2 - 3

1/2 - 3

DETAIL C

SCALE 1 : 2

text ring joint,

optional weld

at back

SS vertical embedment ring,

(weld to text ring not shown)

1/4 x 1 1/2" SS assembly bolts,

weld optional per shop

SS text ring, etched on

reverse (bottom view)

B

SECTION 1-1

SCALE 1 : 12

DETAIL B

SCALE 1 : 2

optional foam glazing strips

to reduce air entrapment

1/4" x 2" SS vertical embedment ring

1/4 x 1 1/2" SS embedment

studs, spacing as noted

top of SS text ring as installed,

with edge relief (typ all parts)

1/2 - 3

1/2 - 3

1/8

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:ASTextRing11.2.33.0.11.412.14/10/20141:34:08PM

DO NOT SCALE

Sheet

2 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales

- 3. DP5 - Text Ring - isometric

11

2"

R42"

65.97

90°

P5 - Text Ring - plan

SCALE 1 : 10

NOTE: confirm part length and count with

Artist to assure fit with student provided text

E

P6 - Embedment Ring - isometric

67.20

R41

1

2

"

P7 - Embedment Ring - plan

SCALE 1 : 10

P7 - Embedment Ring - isometric

66.80

R41

1

4

"

P6 - Embedment Ring - plan

SCALE 1 : 10

DETAIL D

SCALE 1 : 1

edge relief at top of SS text

ring as installed (typ all parts)

do not top weld at end joints of text ring

1/4 x 1 1/2" SS text ring,

etch and grind finish

1"

1"

2"

2"

DETAIL E

SCALE 1 : 2

1/4" x 2" SS vertical embedment

ring , mill finish

3/8" diam. hole for

embedment ring assembly

PART ID PART NAME QTY. WT TOTAL WT MATERIAL FINISH NOTES

P5 Text Ring 4 7.01 28.04 AISI 304 SS Anti-Slip

1/4" thick SS plate, ver. dim.

and sequence w/ Artist

P6 Embedment Ring - inner 2 9.61 19.22 AISI 304 SS Mill 1/4" thick SS plate

P7 Embedment Ring - outer 2 9.67 19.34 AISI 304 SS Mill 1/4" thick SS plate

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:P5textring11.1.11.2.13.0.11.412.14/1/20148:28:47AM

DO NOT SCALE

Sheet

3 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales

- 4. R42"

GG

H

I

J

DETAIL F

SCALE 1 : 8

Rail Branch Parts (4)

Text Ring Parts (4) Embedment Ring Parts below

text ring (4 total)

K

SECTION G-G

SCALE 1 : 8

embedment studs below,

see layouts for location and count

DETAIL H

SCALE 1 : 2

1/4" x 2" SS Embedment Ring below

do not top weld top joints at

text ring, typical all locations

etch and grind 1/4" x 1 1/2"SS Text Ring

1/4" x 1 1/2" SS

embedment stud below

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

3/16

DETAIL I

SCALE 1 : 2

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

3/8" thick SS water-jet cut plate

for all rail and branch parts (typ)

1/4" x 2 1/2" SS embedment anchors,

see bolt layouts for each part

DETAIL J

SCALE 1 : 2

do not top weld any joints at

top of miter, typical all locations

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

3/16

DETAIL K

SCALE 1 : 2

1/4" x 2 1/2" SS embedment anchors,

see bolt layouts for each rail part

3/16

tack 3 places typ

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:AFLafayetteEast11.2.33.0.11.412.14/3/20145:41:09PM

DO NOT SCALE

Sheet

4 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales

- 5. Top View

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

Front View

R6"

typ

Part 1 (back) - anchor bolt layout

SCALE 1 : 5

1/4" x 2 1/2" SS embedment anchors,

bolt location approximate

Note:

All material for rail parts to be 1/4 "

Made in USA SS plate unless noted.

ITEM PART ID PART NAME QTY. WT TOT WT MATERIAL FINISH NOTES

1 P1 Branch 1, 5-rail 1 53.08 53.08 AISI 304 SS Anti-Slip 3/8" thick SS plate

2 H4 Bolts - 1/4" x 2 1/2" SS 30 0.068 2.04 AISI 316 SS - Stainless Steel

Cut Notes - Part 1

Description Qty / Length

Drops 4

Cut Length - outside 386"

Cut Length - inside 128"

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:AS511.2.33.0.11.412.14/11/20149:30:17AM

DO NOT SCALE

Sheet

5 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales

- 6. Top View

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

Front View

R6"

typ

Part 2 (back) - anchor bolt layout

SCALE 1 : 5

1/4" x 2 1/2" SS embedment anchors,

bolt location approximate

Note:

All material for rail parts to be 1/4 "

Made in USA SS plate unless noted.

ITEM PART ID PART NAME QTY. WT TOT WT MATERIAL FINISH NOTES

1 P2 Branch 2, 6-rail 1 60.03 60.03 AISI 304 SS Anti-Slip 3/8" thick SS plate

2 H4 Bolts - 1/4" x 2 1/2" SS 33 0.068 2.244 AISI 316 SS - Stainless Steel

Cut Notes - Part 2

Description Qty / Length

Drops 7

Cut Length - outside 373"

Cut Length - inside 196"

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:AS611.2.33.0.11.412.14/11/20149:30:17AM

DO NOT SCALE

Sheet

6 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales

- 7. Top View

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

Front View

R6"

typ

Part 3 (back) - anchor bolt layout

SCALE 1 : 5

1/4" x 2 1/2" SS embedment anchors,

bolt location approximate

Note:

All material for rail parts to be 1/4 "

Made in USA SS plate unless noted.

ITEM PART ID PART NAME QTY. WT TOT WT MATERIAL FINISH NOTES

1 P3 Branch 3, 6-rail (crossed) 1 60.40 60.4 AISI 304 SS Anti-Slip 3/8" thick SS plate

2 H4 Bolts - 1/4" x 2 1/2" SS 32 0.068 2.176 AISI 316 SS - Stainless Steel

Cut Notes - Part 3

Description Qty / Length

Drops 10

Cut Length - outside 321"

Cut Length - inside 252"

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:AS6x11.2.33.0.11.412.14/11/20149:30:17AM

DO NOT SCALE

Sheet

7 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales

- 8. Top View

surface grind and provide

1/16" edge relief (at face)

typical for all exposed parts

Front View

R6"

typ

Part 4 (back) - anchor bolt layout

SCALE 1 : 5

1/4" x 2 1/2" SS embedment anchors,

bolt location approximate

Note:

All material for rail parts to be 1/4 "

Made in USA SS plate unless noted.

ITEM PART ID PART NAME QTY. WT TOT WT MATERIAL FINISH NOTES

1 P4 Branch 4, 7-rail 1 53.07 53.07 AISI 304 SS Anti-Slip 3/8" thick SS plate

2 H4 Bolts - 1/4" x 2 1/2" SS 34 0.068 2.312 AISI 316 SS - Stainless Steel

Cut Notes - Part 4

Description Qty / Length

Drops 8

Cut Length - outside 385"

Cut Length - inside 223"

Designer:DrawnBy:db

Approved

Prelim

4/14/2014

Revisions

TriMetLafayetteEast

Portland,Oregon

SculptureInstallationforAnneStorrs

davidbalesdesign.com pdxbales@mac.com 503.367.4291

David Bales Design

art architecture visualization

Job ID

22144

Bsheetsize:referencemodel:AS711.2.33.0.11.412.14/11/20149:30:17AM

DO NOT SCALE

Sheet

8 of 8

all art and sculpture © 2014 Anne Storrsall design, drawings and photography © 2014 David Bales