More Related Content

Similar to Brewey Poster Presentation-EDIT 2

Similar to Brewey Poster Presentation-EDIT 2 (20)

Brewey Poster Presentation-EDIT 2

- 1. TEMPLATE DESIGN © 2008

www.PosterPresentations.com

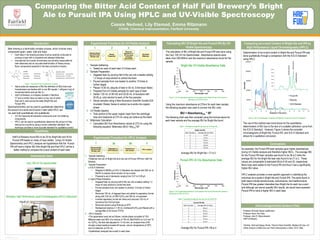

Comparing the Bitter Acid Content of Half Full Brewery’s Bright

Ale to Pursuit IPA Using HPLC and UV-Visible Spectroscopy

Cassie Nedved, Lily Etemad, Emma Ritzmann

CH326, Chemical Instrumentation, Fairfield University

Introduction

Instruments Used

Experimental Procedure for UV-Visible Analysis

Experimental Procedure for HPLC Analysis

Calculating IBU Of Bright Ale and Pursuit IPA By UV-

Visible Spectroscopy

The calculation of IBU of Bright Ale and Pursuit IPA was done using

the Cary 100 UV-Vis Spectrometer. Absorbance spectra were

taken from 200-800nm and the maximum absorbance found for the

sample.

Using the maximum absorbance at 275nm for each beer sample,

the following equation was used to convert into IBU units.

Comparing iso-α-acid Content of Bright Ale and IPA by

High Performance Liquid Chromatography (HPLC)

Conclusions

Acknowledgements/Literature Cited

Cary 100 UV-Vis Spectrometer

-0.2

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

200 300 400 500 600 700 800

Absorbance

Wavelength (nm)

Figure 2: UV-Vis absorbance spectrum of one sample of the Bright Ale beer with maximum

absorbance of 0.578 at 275nm.

IBU = Absorbance275 * 501

The following chart was then compiled using the formula above for

each beer sample and the average IBU for Bright Ale found.

Bright Ale IBU

Beer Number Average IBU per Beer

1 17±0

2 17±1

3 21±1

4 24±6

5 24±3

6 23±4

Average IBU for Bright Ale = 21±3

Pursuit IPA UV-Vis Absorbance Data

-0.2

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

200 300 400 500 600 700 800

Asborbance

Wavelength (nm)

Figure 2: UV-Vis absorbance spectrum of one sample of the Pursuit IPA beer with maximum

absorbance of 0.661 at 275nm.

Pursuit IPA IBU

Beer Number Average IBU Per Beer

1 38±2

2 35±1

3 36±0

4 34±1

5 37±3

6 37±2

Average IBU for Pursuit IPA =36±2

Bright Ale UV-Visible Absorbance Data

Obtained Bright

Ale and Pursuit

IPA beer cans

Sample

Preparation

Measured

absorbance at

275 nm using

UV-Visible

spectrometer

Calculated

Bitterness

1. Sample Gathering

Tested six cans of each beer 3-5 times each

2. Sample Preparation

Degased beer by pouring half of the can into a beaker adding

1-2 drops of octyl alcohol to control the foam

Poured samples from one beaker to another 10 times to

further degas

Placed 10.00 mL aliquots of beer in 50 mL Erlenmeyer flasks

Prepared five UV-Visible samples for each type of beer

Added 1.00 mL of 3N HCl and 20.00 mL of isooctane with

50.00 μL octyl alcohol to each of the five samples

Shook samples using a New Brunswick Scientific Excella E24

Incubator Shaker Series to extract iso-α-acids into organic

phase

3. UV-Visible Spectra

Took portion of the upper organic layer from the centrifuge

tube and measured at 275 nm using iso-octane as the blank

4. Bitterness Calculation

Calculated IBU from Absorbance values at 275 nm using the

following equation: Bitterness (IBU)= Abs275*501

Shimadzu High Performance Liquid Chromatography (HPLC) Instrument

As expected, the Pursuit IPA beer samples gave higher absorbances

during UV-Visible analysis and therefore higher IBU’s. The average IBU

for the Pursuit IPA beer samples was found to be 36±2 while the

average IBU for the Bright Ale beer was found to be 21±3. These

values are comparable to estimated IBUs of 40 and 20, respectively.

More hops were added to the Pursuit IPA and thus it had a significantly

higher IBU value.

HPLC analysis provides a more specific approach in identifying the

individual iso-α-acids in Bright Ale and Pursuit IPA. The acids found in

both beers include isocohumuole, isohumulone, and isadhumulone.

Pursuit IPA has greater intensities than Bright Ale for each iso-α-acid

and although we cannot quantify IBU results, we would have expected

Pursuit IPA to have a higher IBU in each beer.

Table 2: Calculated average IBU per beer can for Pursuit IPA

Table 1: Calculated average IBU per beer can for Bright Ale

Half Full Brewery found IBU to be 20 for Bright Ale and 40 for

Pursuit IPA based on mass of hops added. Using UV-Visible

Spectrometry and HPLC analysis we hypothesize that the Pursuit

IPA will have a higher IBU than Bright Ale and that HPLC will be a

better method to compare the α-acid content of each beer.

1 2 3 4

Obtained Bright

Ale and Pursuit

IPA beer cans

Preparation of

ICS-I3 Standard

Preparation of

beer samples

HPLC analysis

Professor Amanda Harper-Leatherman

Professor Aaron Van Dyke

Professor John R. Miecznikowski

Half Full Brewery

1Strother, Todd and Keppy, Nicole. Thermo Fisher Scientific, Madison,Wi Usa. UV-

Visible Analysis of Bitterness and Total Carbohydrates in Beer. 2013. Web.

1 2a 2b 3

1. Sample Gathering

Obtained one can of Bright Ale and one can of Pursuit IPA from Half Full

Brewery

2. Sample Preparation

a.ICS-I3 Standard

• Weighed 0.08026 g of ICS-13 Standard and diluted with 500 mL of

MeOH to prepare stock solution of iso-α-acids

• Prepared a set of standards ranging from 0.01 to 0.08 g/L

b.Liquid Phase Extraction

• Degased beer by pouring half of the can into a beaker adding 1-2

drops of octyl alcohol to control the foam

• Poured samples from one beaker to another 10 times to further

degas

• Removed 100 mL of degased beer and added to separatory funnel

along with 5.00 mL of 20M H3PO4 and 200 mL of isooctane

• Inverted separatory funnel ten times and removed 125 mL of

isooctane from the top layer

• Removed solvent using Rotovap at 30⁰C

• Redissolved residue in 1.00 mL of ethanol/H3PO4 and filtered with a

syringe filter (0.20 micron PTFE)

3. HPLC Analysis

The parameters were set as follows: mobile phase consisted of 10%

Millipore water and 90% of a mixture of 750 mL MeOH/240 mL H2O and 10

mL H3PO4, the flow rate adjusted to 1.5 mL/min, an analysis time of 60

minutes unless baseline leveled off sooner, column temperature of 35⁰C,

and UV-detection at 270 nm

Qualitatively analyzed iso-α-acid in each beer

0

50000

100000

150000

200000

250000

0 1 2 3 4 5 6 7 8 9 10 11 12

Intenstity

Retention Time (min)

Figure 3: HPLC chromatogram of samples of Bright Ale, Pursuit IPA, and ICS-I3 Standard

Determination of iso-α-acid content in Bright Ale and Pursuit IPA was

done qualitatively through a comparison with the ICS-I3 Standard

using HPLC.

The use of this method was inconclusive for the quantitative

determination of IBU due to the lack of a suitable calibration curve from

the ICS-I3 Standard. However, Figure 3 shows the compiled

chromatograms of Bright Ale, Pursuit IPA, and ICS-I3 Standard and

allows for a qualitative conclusion.

0

10000

20000

30000

40000

50000

60000

0 1 2 3 4 5

Isocohumulone

Isohumulone

Isoadhumulone

Beer brewing is a technically complex process, which involves many

components (grain, water, malt and hops)

• Each step in the brewing process must be carefully conducted to

produce a beer with a consistent and pleasant bitterness

• Hop-derived iso-α-acids (humulones) are primarily responsible for

beer bitterness and an accurate determination of these primary

flavor components essential in the beer production industry

Figure 1: Structures of iso-α-acids and -α-acids

• Alpha acids are measured in IBU-the definition of IBUs that most

homebrewers are familiar with is one IBU equals 1 milligram (mg) of

isomerized alpha acid per liter (L)

• Half Full Brewery is a brewery located in Stamford,

CT and currently have six beers on tap, two of which

they sell in cans across the state (Bright Ale and

Pursuit IPA)

Spectrophotometry can be used to quantitatively determine

the amount of α-acids and β-acids in beer while HPLC can

be used both quantitatively and qualitatively

• UV-Vis measures all extracted compounds even non-bittering

components

• HPLC can be used to quantitatively determine the amount of Hop-

derived iso-α-acids by using a known calibration standard- this

technique provides a more accurate standard for qualitative control

Hypothesis