TOYOTA PRODUCTION SYSTEM BEST PRACTICES

•Download as RTF, PDF•

0 likes•836 views

Report

Share

Report

Share

Recommended

Recommended

More Related Content

More from BRIAN M. DUNLAP

More from BRIAN M. DUNLAP (20)

SAMPLE GLOBAL REACH MARKETING AND OPERATIONS CONSULTING-239 COUNTRIES

SAMPLE GLOBAL REACH MARKETING AND OPERATIONS CONSULTING-239 COUNTRIES

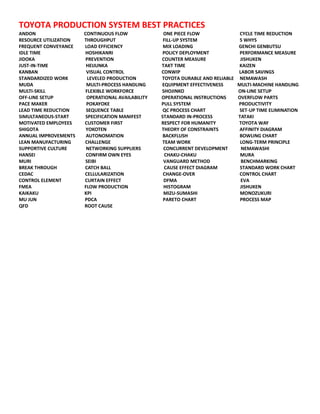

TOYOTA PRODUCTION SYSTEM BEST PRACTICES

- 1. TOYOTA PRODUCTION SYSTEM BEST PRACTICES ANDON CONTINUOUS FLOW ONE PIECE FLOW CYCLE TIME REDUCTION RESOURCE UTILIZATION THROUGHPUT FILL-UP SYSTEM 5 WHYS FREQUENT CONVEYANCE LOAD EFFICIENCY MIX LOADING GENCHI GENBUTSU IDLE TIME HOSHIKANRI POLICY DEPLOYMENT PERFORMANCE MEASURE JIDOKA PREVENTION COUNTER MEASURE JISHUKEN JUST-IN-TIME HEIJUNKA TAKT TIME KAIZEN KANBAN VISUAL CONTROL CONWIP LABOR SAVINGS STANDARDIZED WORK LEVELED PRODUCTION TOYOTA DURABLE AND RELIABLE NEMAWASH MUDA MULTI-PROCESS HANDLING EQUIPMENT EFFECTIVENESS MULTI-MACHINE HANDLING MULTI-SKILL FLEXIBLE WORKFORCE SHOJINKO ON-LINE SETUP OFF-LINE SETUP OPERATIONAL AVAILABILITY OPERATIONAL INSTRUCTIONS OVERFLOW PARTS PACE MAKER POKAYOKE PULL SYSTEM PRODUCTIVITY LEAD TIME REDUCTION SEQUENCE TABLE QC PROCESS CHART SET-UP TIME ELIMINATION SIMULTANEOUS-START SPECIFICATION MANIFEST STANDARD IN-PROCESS TATAKI MOTIVATED EMPLOYEES CUSTOMER FIRST RESPECT FOR HUMANITY TOYOTA WAY SHIGOTA YOKOTEN THEORY OF CONSTRAINTS AFFINITY DIAGRAM ANNUAL IMPROVEMENTS AUTONOMATION BACKFLUSH BOWLING CHART LEAN MANUFACTURING CHALLENGE TEAM WORK LONG-TERM PRINCIPLE SUPPORTIVE CULTURE NETWORKING SUPPLIERS CONCURRENT DEVELOPMENT NEMAWASHI HANSEI CONFIRM OWN EYES CHAKU-CHAKU MURA MURI SEIBI VANGUARD METHOD BENCHMARKING BREAK THROUGH CATCH BALL CAUSE EFFECT DIAGRAM STANDARD WORK CHART CEDAC CELLULARIZATION CHANGE-OVER CONTROL CHART CONTROL ELEMENT CURTAIN EFFECT DFMA EVA FMEA FLOW PRODUCTION HISTOGRAM JISHUKEN KAIKAKU KPI MIZU-SUMASHI MONOZUKURI MU JUN PDCA PARETO CHART PROCESS MAP QFD ROOT CAUSE