TRAFFIC MANAGEMENT AROUND VEHICLES THAT REQUIRE OUTRIGGERS FOR STABILISATION 2

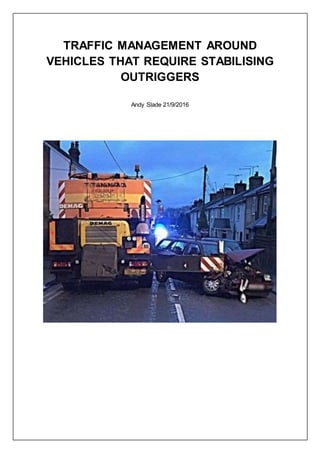

- 1. TRAFFIC MANAGEMENT AROUND VEHICLES THAT REQUIRE STABILISING OUTRIGGERS Andy Slade 21/9/2016

- 2. In recent months the question of what constitutes reasonable and safe traffic management around vehicles that require outriggers for stabilisation has been raised by stakeholders in the Victorian construction industry. Some employers and their representatives have indicated that a traffic management plan that meets the Australian Standard AS1742.3 “Manual of Uniform Traffic Control Devices” and the Vicroads “Worksite Safety – Traffic Management Code of Practice.,” is sufficient evidence for a safe system of work. In relation to both the Australian standard and the Code of Practice, each document makes reference to the requirement for a duty holder to ensure the safety of workers and other persons so far as reasonably practicable. Below is an extract from AS1742.3

- 3. The reference in the Vicroads Code of Practice is equally clear and refers directly to the OHS Act 2004 and regulations. The Code of Practice also places on the “Works Manager”, who can be taken to be the construction company, an obligation to audit the traffic management plan and its implementation on the road to confirm that it is working as required and to identify that all risks to employees and other persons are being controlled so far as reasonably practicable. As a result principal contractors who are relying on a traffic management plan that does not eliminate or control the risk to site employees or the travelling public so far as reasonably practicable will be in breach of the OHS Act 2004 and regulations In the case of a traffic management plan being set up around any vehicle that requires outriggers to stabilise it while it is in use, including mobile cranes, vehicle loading cranes (VLCs), or concrete placement boom trucks, consideration must be given to the risks associated with the plant vehicle’s outriggers being struck by a passing out of control vehicle. A common practice when controlling traffic past vehicles with outriggers may be to slow vehicles to 40kmh, provide a separation distance of approximately 1.3 metres between the live traffic lane and the outriggers of the plant vehicle, delineate this separation area with high visibility plastic bollards and use traffic management employees holding stop/slow bats to control the flow of traffic if the road has been reduced to one lane. The question is: Does this type of traffic management set up eliminate or reduce so far as reasonably practicable the risks associated with other vehicles potentially striking the outriggers of a crane or concrete boom, potentially destabilising the vehicle, resulting in a collapse? Below are some examples where concrete placement boom pumps have become unstable and collapsed causing serious injury. The mechanism or cause for the destabilisation and subsequent collapse has not been defined for all examples, however, it is reasonable to say that should a vehicle such as a car, bus or truck impacts upon a plant vehicle’s outriggers, even at low speed, the result could likely be the destabilising of the plant vehicle followed by collapse.

- 4. Figure 1 A NSW Ambulance spokeswoman said a man, aged in his 30s, suffered serious injuries after he was hit by equipment when the concrete boom pump collapsed. The construction worker was pouring concrete in a stairwell when the leg of the crane snapped, sending it crashing into the brick wall above him. The man was knocked over by the rubber boom. Figure 2 AN Orange building worker has been critically injured on a site in West Orange after being pinned under a concrete pump boom that collapsed around 7.30am.

- 5. Figure 3 A SERIOUSLYinjured construction site worker was flown to hospital by CareFlight after the medical team rescued him from freshly poured concrete on a building site near Camden late yesterday. The CareFlight doctor said the man, aged in his 40s, suffered a severe scalp injury and blood loss, and then collapsed into a freshly poured concrete trench when hit by the boom from a concrete pump. When undertaking site inspections with a focus on the adequacy of traffic management, duty Holders should assess the traffic management plan and road set up to ensure that the risks to plant using outriggers have been controlled so far as reasonably practicable. Any assessment should follow the auditing guidelines contained in the Vicroads Code of Practice and should consider the following information contained in the code.

- 6. When using the audit/assessment criteria set out above in a typical situation where there is only a separation distance of 1.3 metres and plastic bollards to separate live traffic lanes from plant vehicle outriggers, it would be understandable for any person to form a reasonable belief that risks exist as a separation distance and bollards do not prevent other vehicles impacting outriggers should the following occur. Other road users failing to comply with the implemented traffic management plan owing to intoxication, distraction or illness. Larger vehicles such as buses being on the road owing to public transport operations Adverse road conditions owing to the weather Traffic volumes during peak periods Therefore, in reply to the question that was posed above, a separation distance and bollards is inadequate protection for outriggers and does not control all the risks to employees and other persons so far as reasonably practicable If there is insufficient protection for vehicle outriggers and there is a risk to employees and other persons from road users striking the outriggers, potentially collapsing the plant, then additional safety controls must be implemented by the Principal Contractor to further reduce or eliminate the hazards and associated risks even if those additional safety controls were not identified in the original traffic management plan. As a result it may be reasonably practicable for a Principal Contractor to implement the following controls. Install water filled plastic barriers in front of and adjacent to outriggers. Establish a permanent loading zone protected with concrete barriers or steel crash attenuation bollards installed into the road.

- 7. Park a traffic management crash attenuation vehicle on the approaches to the work zone. Implement an Ironman barrier system. This system allows individual or small sections of barriers to be raised onto an internal jockey wheel assembly allowing duty holders to simply relocate barriers around sites without the use of any additional machinery. CONCLUSION The risk of serious injury to construction workers following the collapse of plant such as concrete placement booms is well illustrated in examples above. All effort must be made to eliminate outriggers being struck by passing vehicles thereby destabilised the plant. These efforts must be made for duty holders to maintain their obligations under section 21 of the OHS Act 2004. When assessing the workplace, duty holders should also consider observations about the work being conducted, the location on site to where concrete is being pumped or items are to be crane lifted and the proximity of workers to the concrete placement boom hose or the crane lifted loads. Simply relying on a traffic management plan complying with the Australian standards or a code of practice may not be good enough for a Principal Contractor to comply with sections 21 and 23 of the OHS Act 2004.