Report

Share

Download to read offline

Recommended

More Related Content

Featured

Featured (20)

Product Design Trends in 2024 | Teenage Engineerings

Product Design Trends in 2024 | Teenage Engineerings

How Race, Age and Gender Shape Attitudes Towards Mental Health

How Race, Age and Gender Shape Attitudes Towards Mental Health

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

Content Methodology: A Best Practices Report (Webinar)

Content Methodology: A Best Practices Report (Webinar)

How to Prepare For a Successful Job Search for 2024

How to Prepare For a Successful Job Search for 2024

Social Media Marketing Trends 2024 // The Global Indie Insights

Social Media Marketing Trends 2024 // The Global Indie Insights

Trends In Paid Search: Navigating The Digital Landscape In 2024

Trends In Paid Search: Navigating The Digital Landscape In 2024

5 Public speaking tips from TED - Visualized summary

5 Public speaking tips from TED - Visualized summary

Google's Just Not That Into You: Understanding Core Updates & Search Intent

Google's Just Not That Into You: Understanding Core Updates & Search Intent

The six step guide to practical project management

The six step guide to practical project management

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

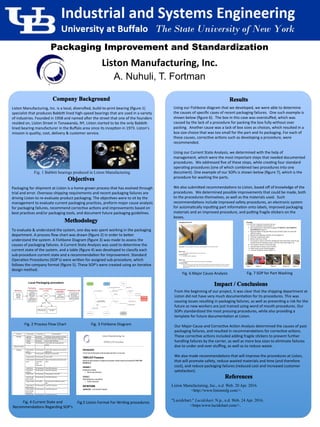

Poster-Format-r2-2-2

- 1. Liston Manufacturing, Inc. is a local, diversified, build-to-print bearing (figure 1) specialist that produces Babbi? lined high-speed bearings that are used in a variety of industries. Founded in 1958 and named aFer the street that one of the founders resided on, Liston Street in Tonawanda, NY, Liston started to be the only Babbi?- lined bearing manufacturer in the Buffalo area since its incepMon in 1973. Liston’s mission is quality, cost, delivery & customer service. Liston Manufacturing, Inc. A. Nuhuli, T. Fortman Packaging for shipment at Liston is a home-grown process that has evolved through trial and error. Overseas shipping requirements and recent packaging failures are driving Liston to re-evaluate product packaging. The objecMves were to sit by the management to evaluate current packaging pracMces, preform major cause analysis for packaging failures, recommend correcMve acMons and improvements based on best pracMces and/or packaging tools, and document future packaging guidelines. Using our Fishbone diagram that we developed, we were able to determine the causes of specific cases of recent packaging failures. One such example is shown below (figure 6). The box in this case was overstuffed, which was caused by the lack of a procedure for packing the box fully without over packing. Another cause was a lack of box sizes as choices, which resulted in a box size choice that was too small for the part and its packaging. For each of these causes, correcMve acMons such as developing a procedure, were recommended. Using our Current State Analysis, we determined with the help of management, which were the most important steps that needed documented procedures. We addressed five of these steps, while creaMng four standard operaMng procedures (one of which combined two procedures into one document). One example of our SOPs is shown below (figure 7), which is the procedure for washing the parts. We also submi?ed recommendaMons to Liston, based off of knowledge of the procedures. We determined possible improvements that could be made, both to the procedures themselves, as well as the materials used. Such recommendaMons include improved safety procedures, an electronic system for automaMcally inpu_ng part informaMon onto labels, improved packaging materials and an improved procedure, and pu_ng fragile sMckers on the boxes. From the beginning of our project, it was clear that the shipping department at Liston did not have very much documentaMon for its procedures. This was causing issues resulMng in packaging failures, as well as presenMng a risk for the future as new workers are just trained using word of mouth procedures. Our SOPs standardized the most pressing procedures, while also providing a template for future documentaMon at Liston. Our Major Cause and CorrecMve AcMon Analysis determined the causes of past packaging failures, and resulted in recommendaMons for correcMve acMons. These correcMve acMons included adding fragile sMckers to prevent further handling failures by the carrier, as well as more box sizes to eliminate failures due to under and over stuffing, as well as to reduce waste. We also made recommendaMons that will improve the procedures at Liston, that will promote safety, reduce wasted materials and Mme (and therefore cost), and reduce packaging failures (reduced cost and increased customer saMsfacMon). Liston Manufacturing, Inc., n.d. Web. 20 Apr. 2016. <http://www.listonmfg.com/>. "Lucidchart." Lucidchart. N.p., n.d. Web. 24 Apr. 2016. <https:www.lucidchart.com/>. Packaging Improvement and Standardization To evaluate & understand the system, one day was spent working in the packaging department. A process flow chart was drawn (figure 2) in order to be?er understand the system. A Fishbone Diagram (figure 3) was made to assess the causes of packaging failures. A Current State Analysis was used to determine the current state of the system, and a table (figure 4) was developed to classify each sub-procedure current state and a recommendaMon for improvement. Standard OperaMon Procedures (SOP’s) were wri?en for assigned sub-procedure, which follows the company format (figure 5). These SOP’s were created using an iteraMve design method. Fig. 3 Fishbone Diagram Fig. 2 Process Flow Chart Fig. 4 Current State and RecommendaMons Regarding SOP’s Fig.5 Liston Format For WriMng procedures Fig. 6 Major Cause Analysis Fig. 7 SOP for Part Washing Fig. 1 Babbitt bearings produced in Liston Manufacturing