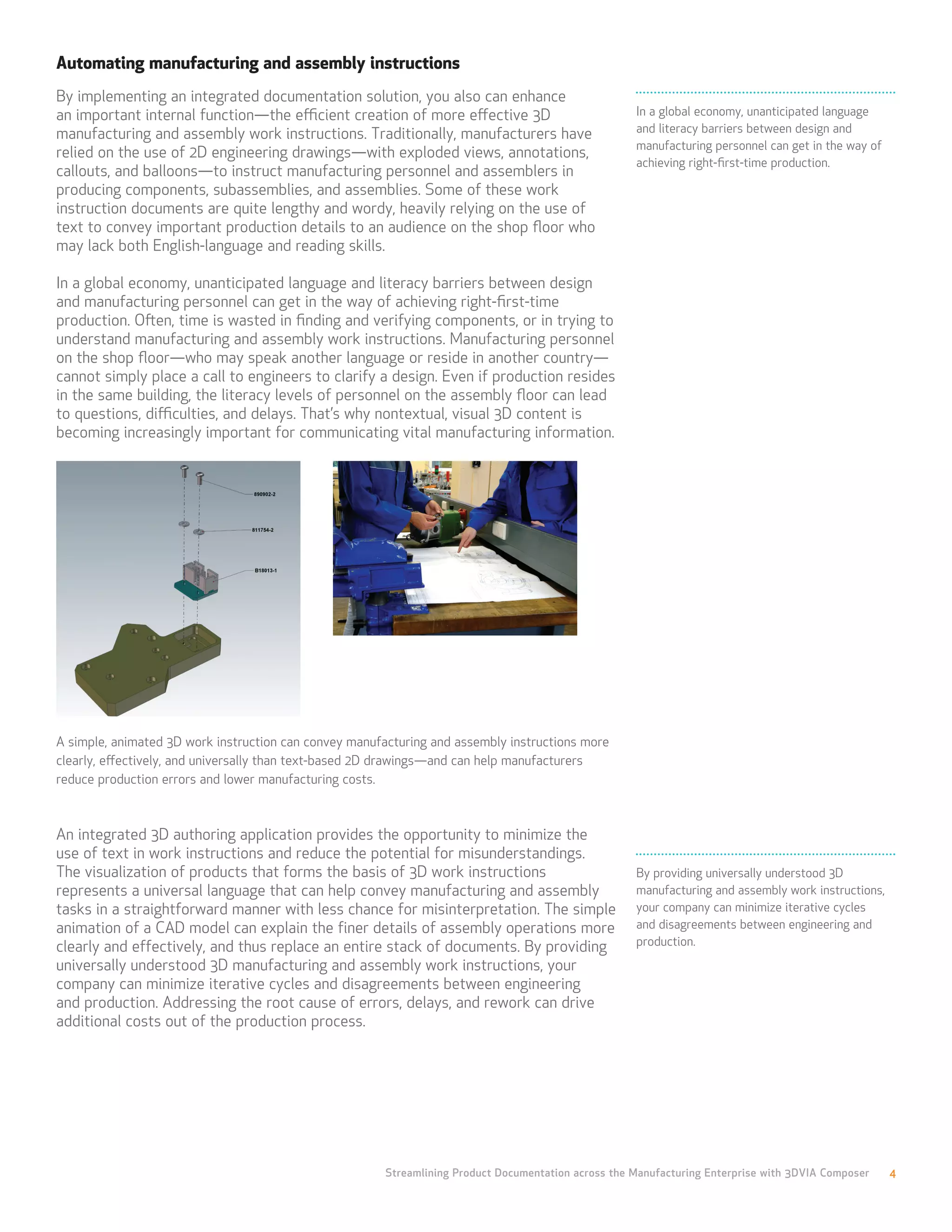

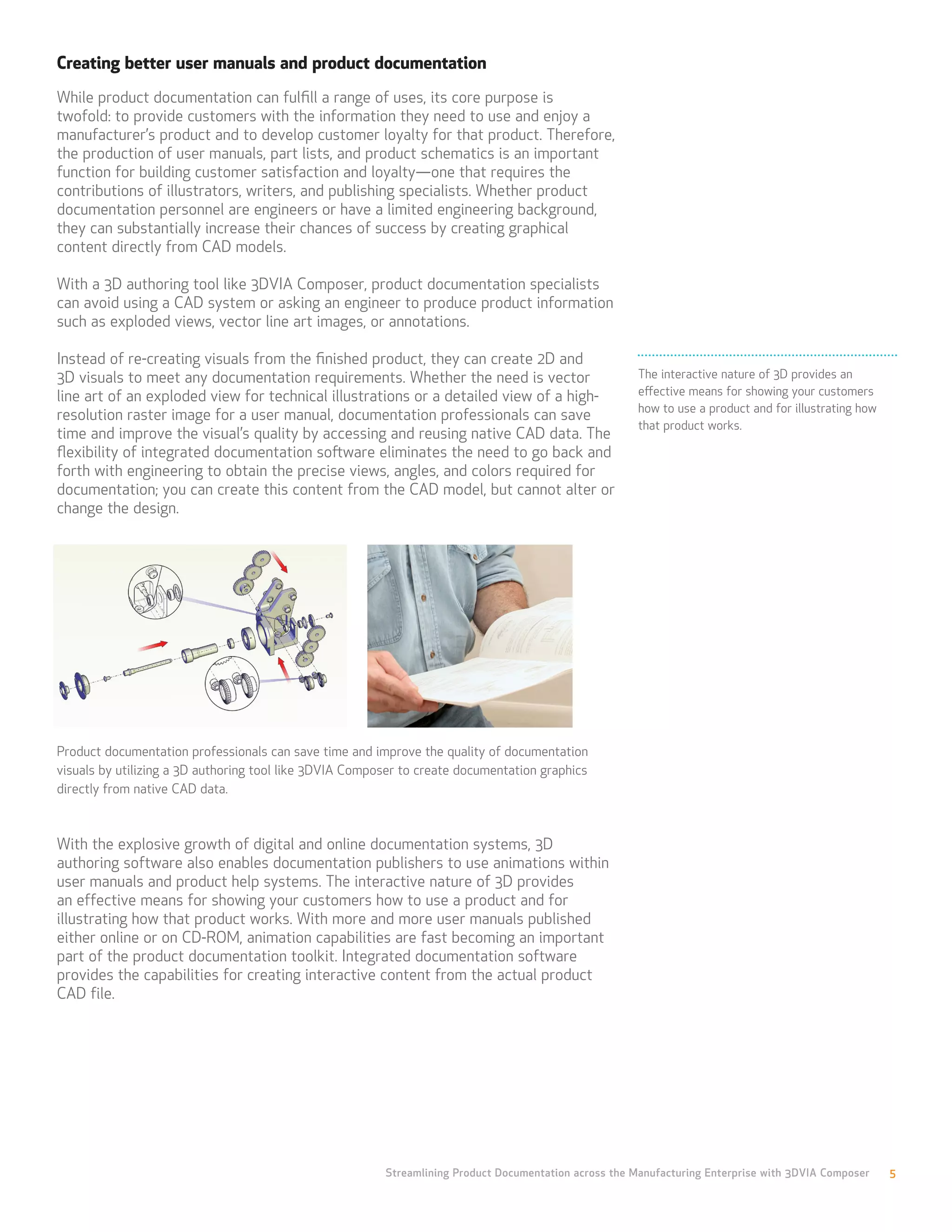

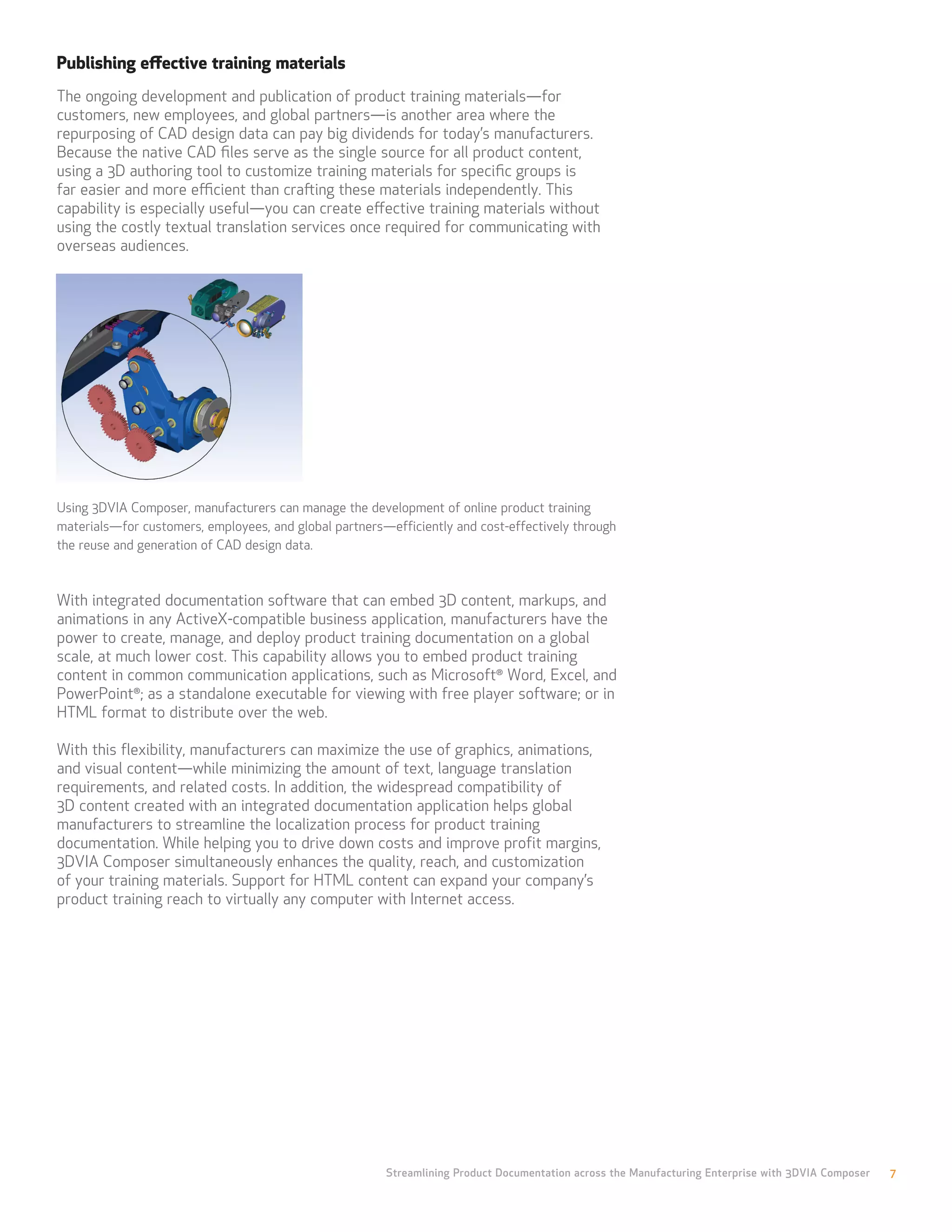

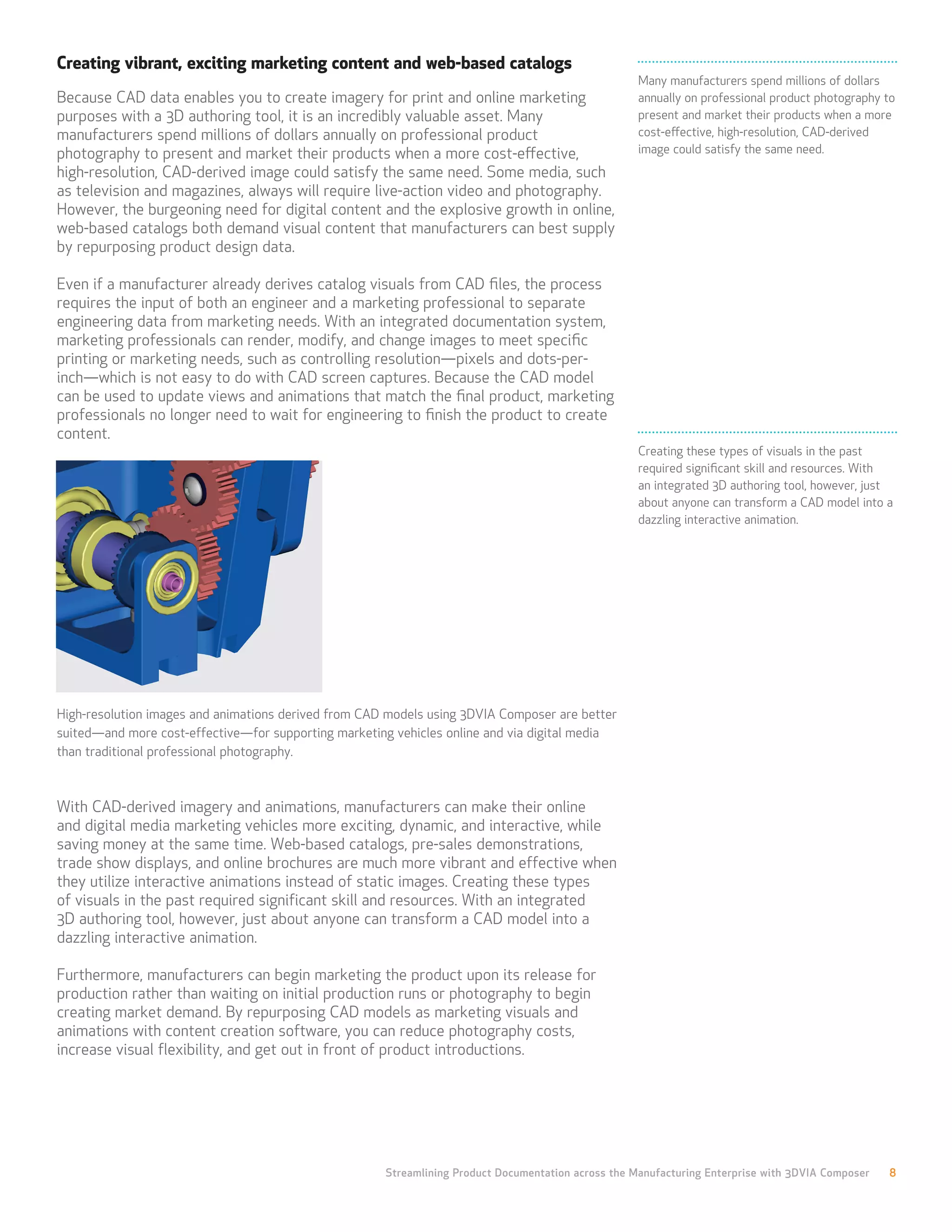

Using 3DVIA Composer software, manufacturers can generate CAD data to meet documentation, assembly, manufacturing, training, service, and marketing content needs, automatically and simultaneously. 3DVIA Composer enables you to produce documentation as much as 30 percent faster than with conventional methods, and realize significant ROI by reducing documentation, training, and localization costs. A 3D authoring tool like 3DVIA Composer allows manufacturers to streamline product documentation processes and reuse CAD data across the manufacturing enterprise.