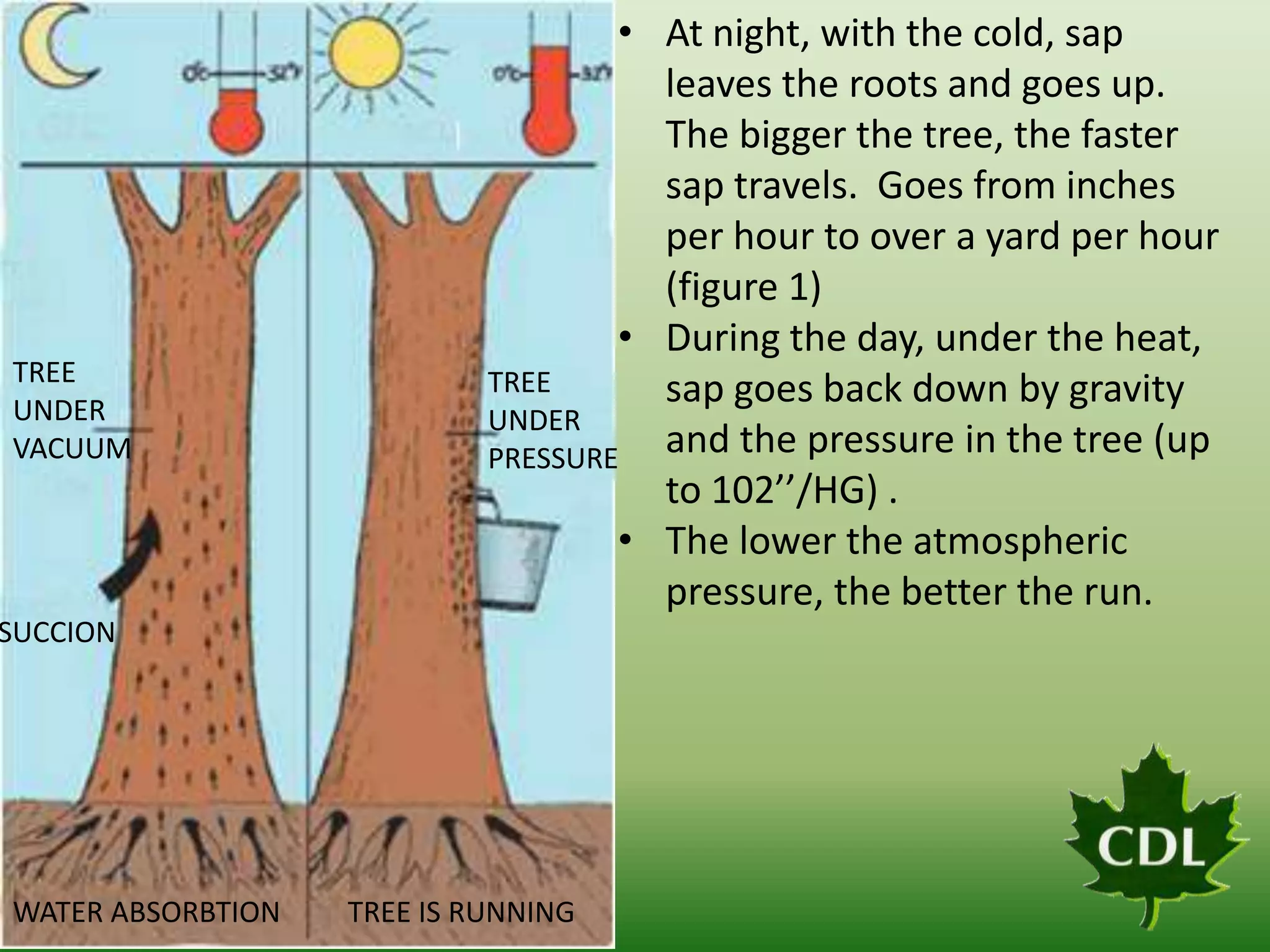

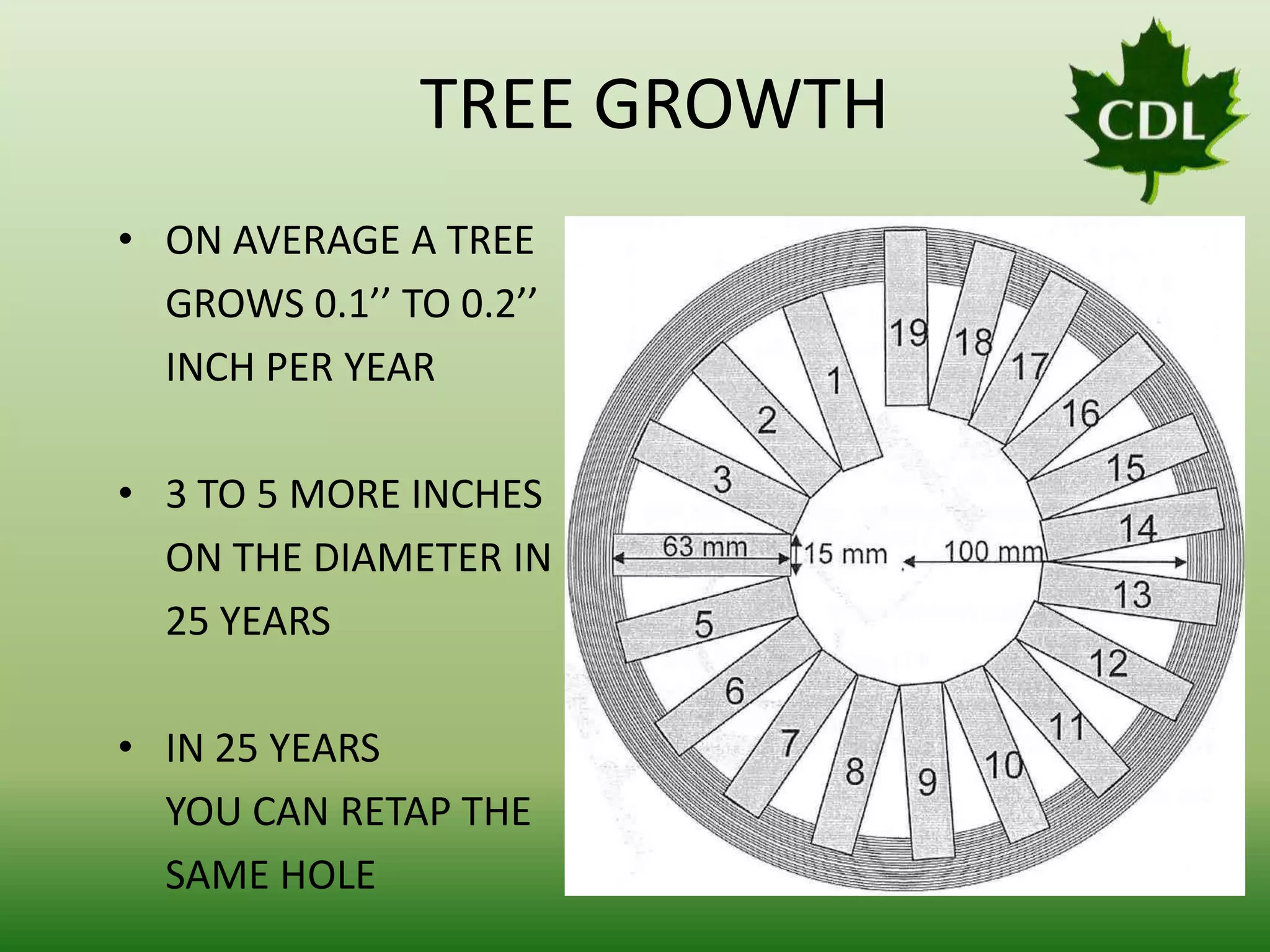

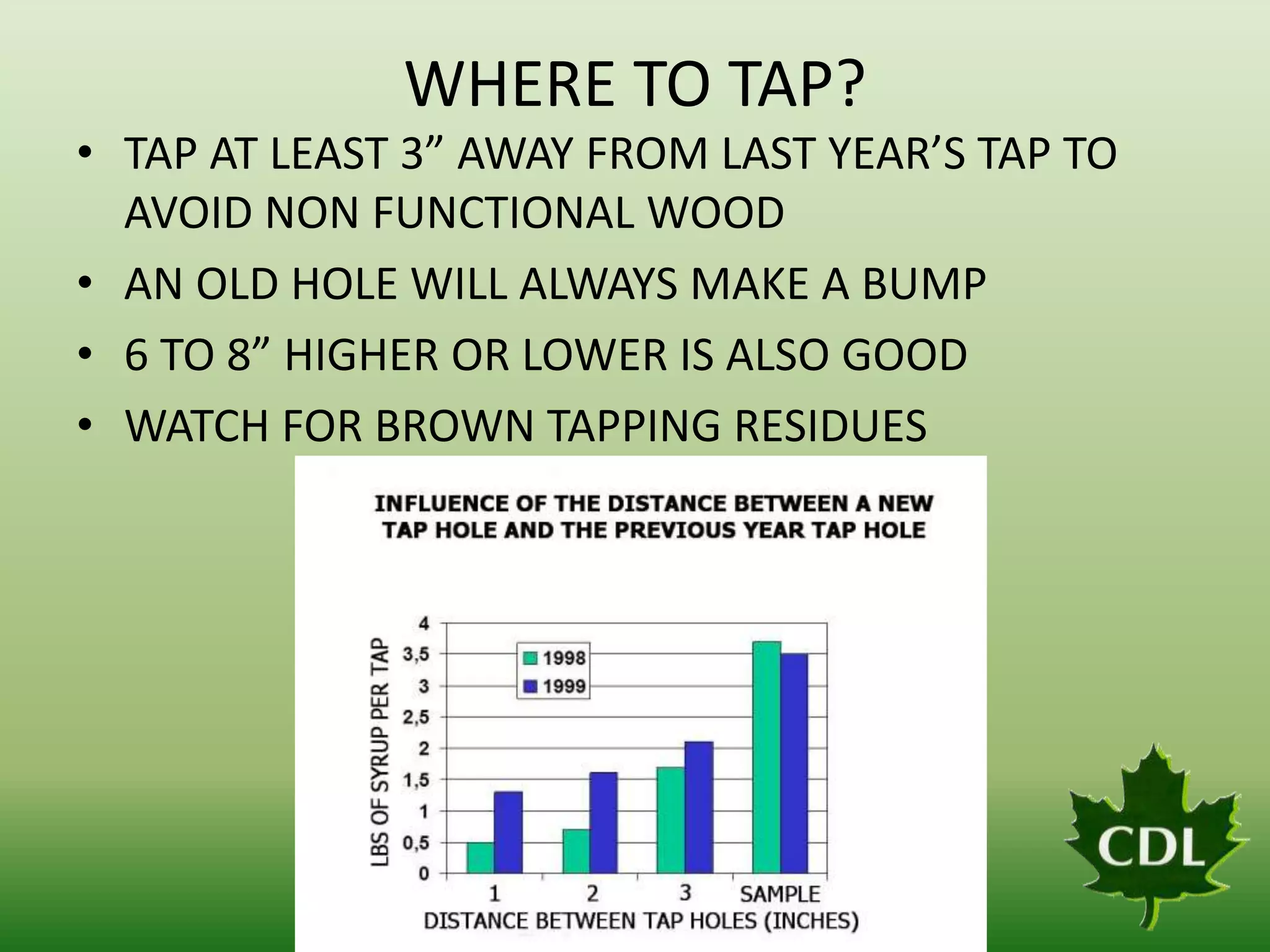

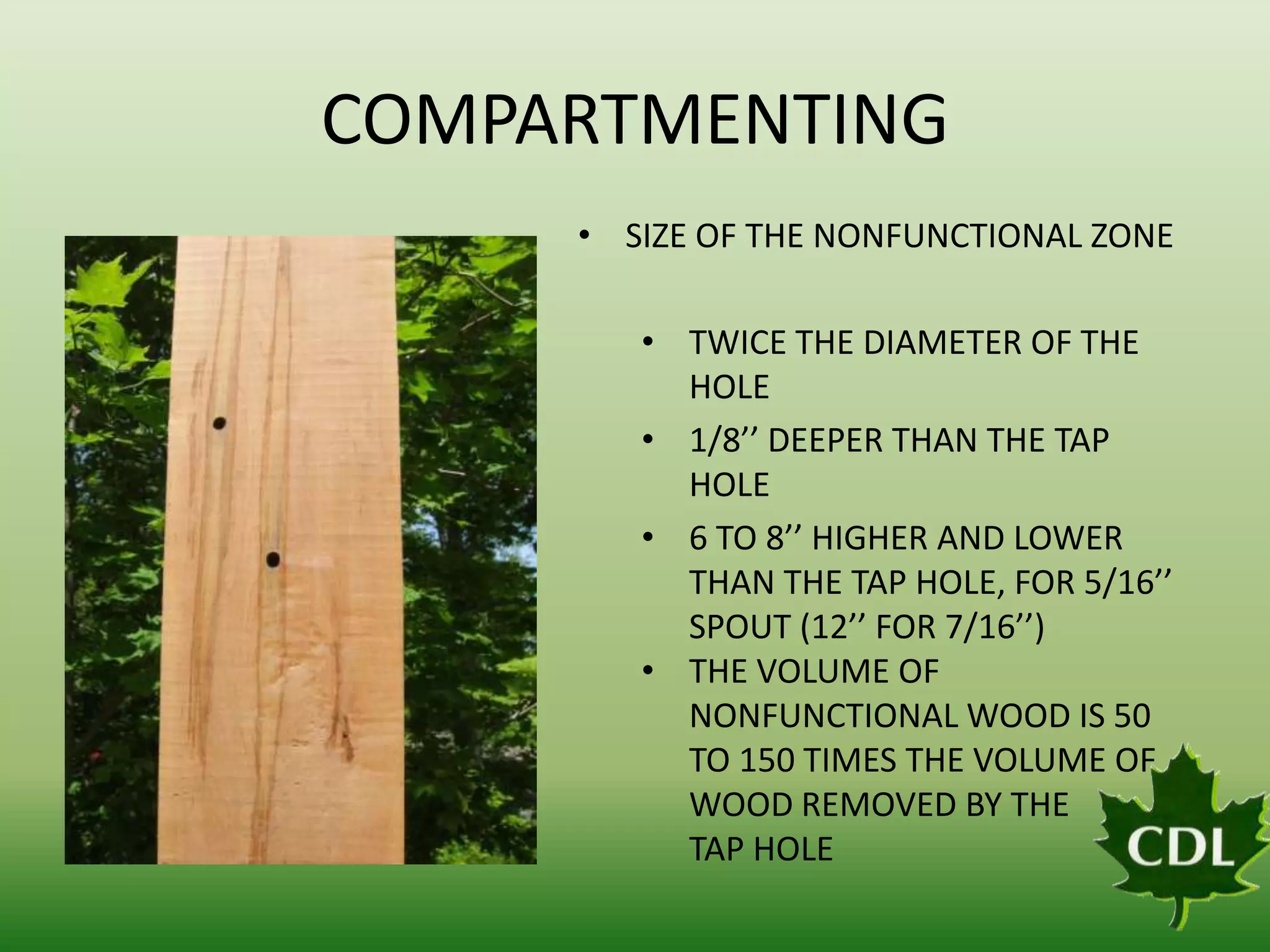

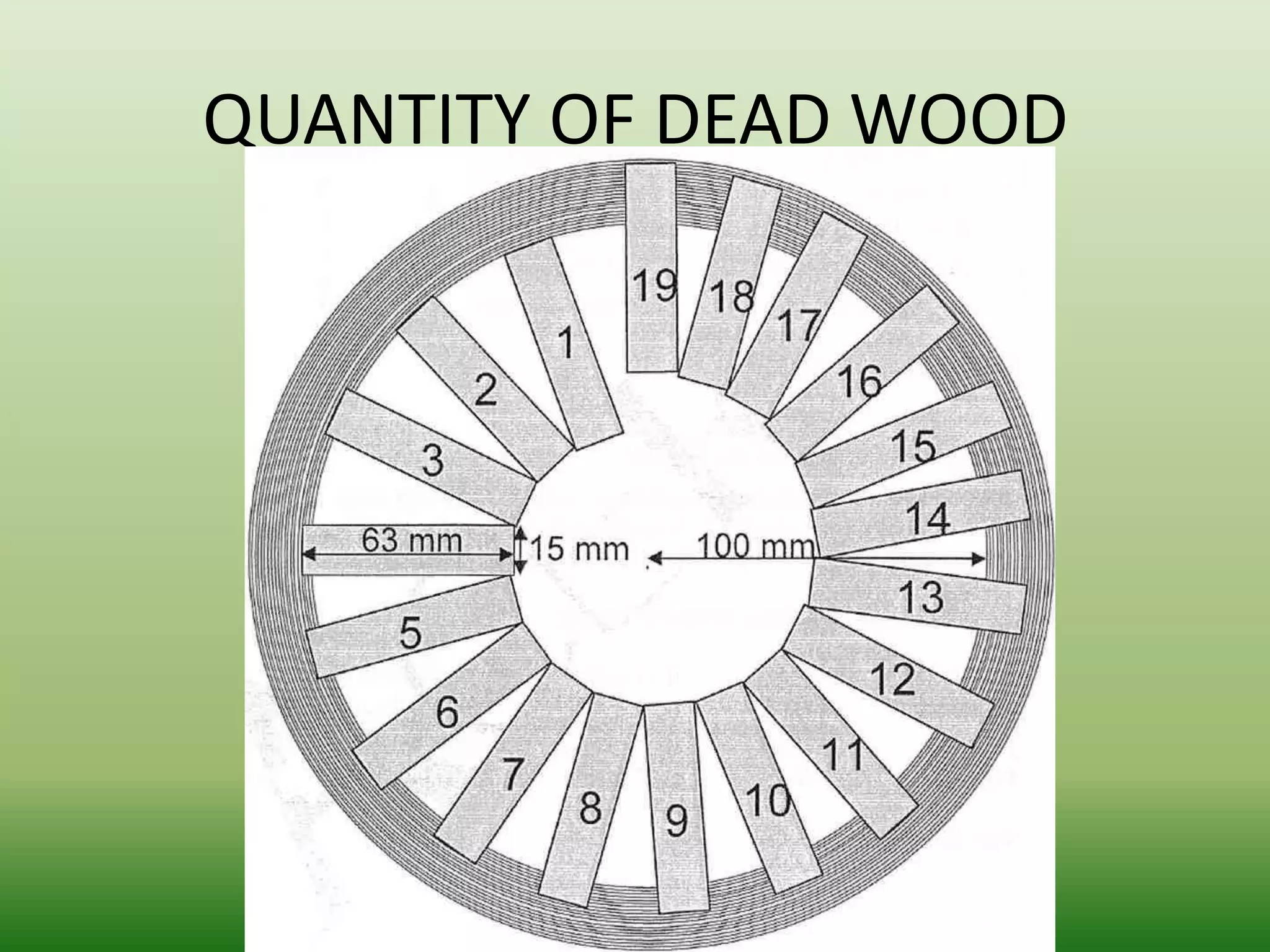

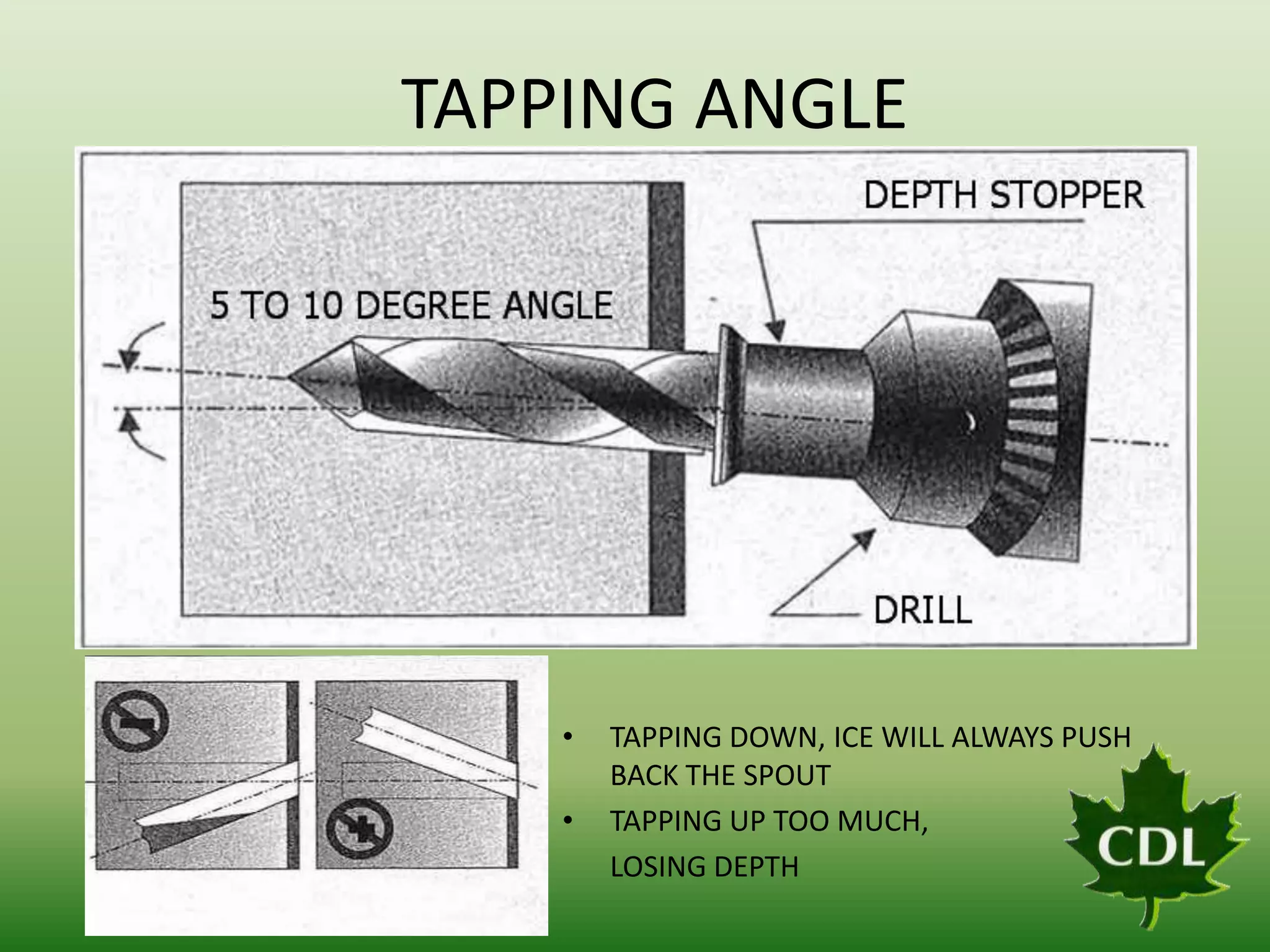

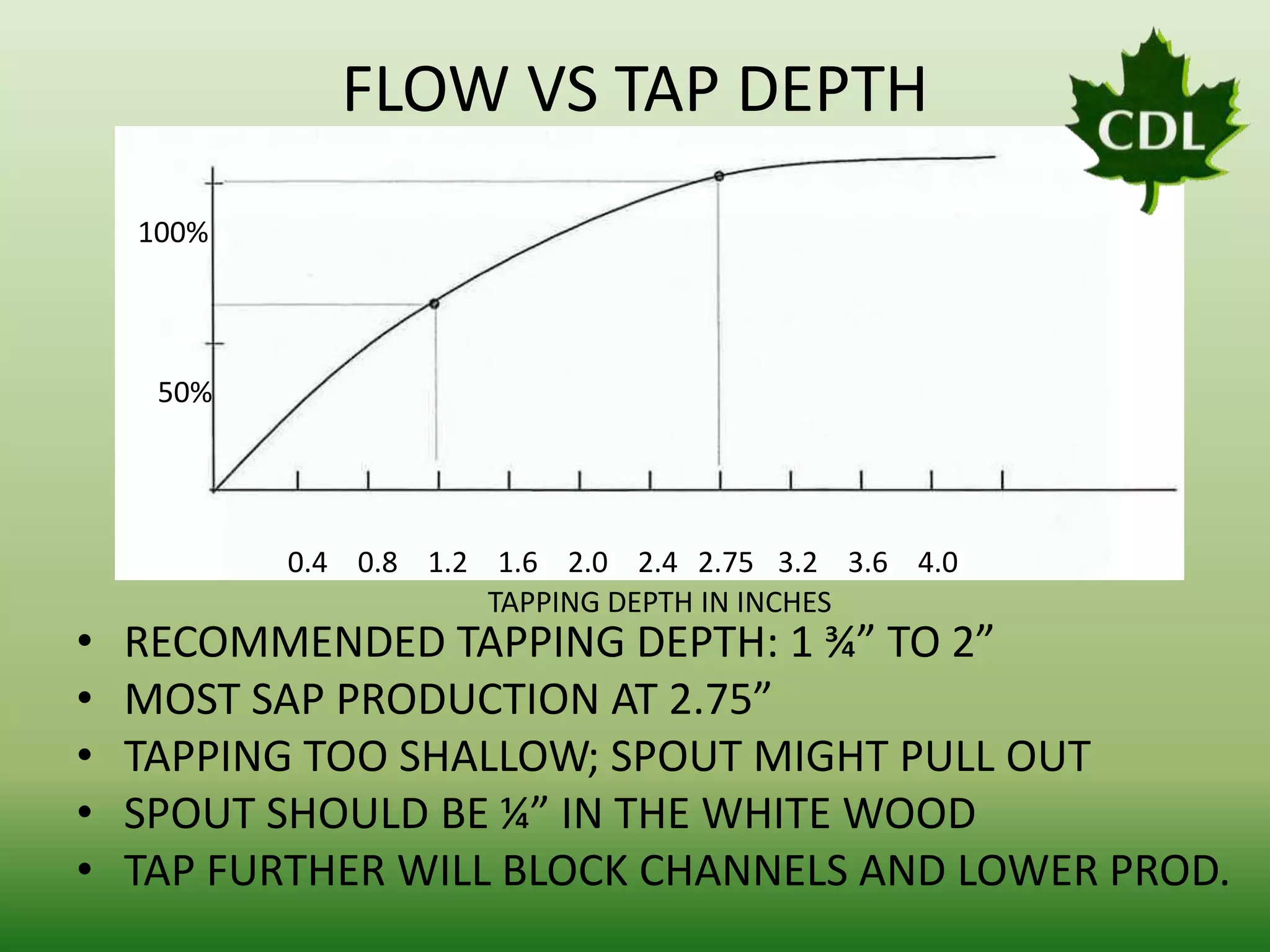

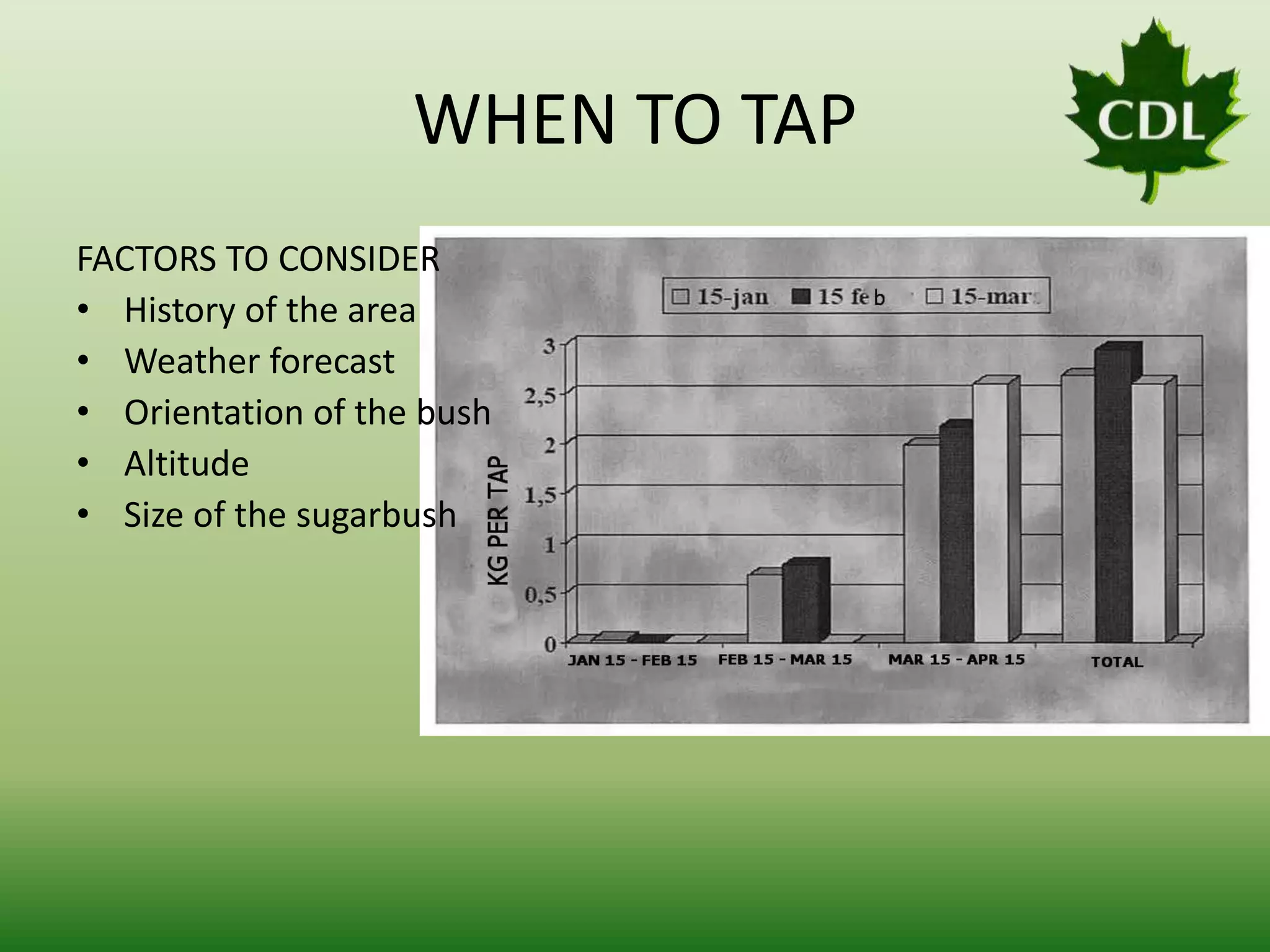

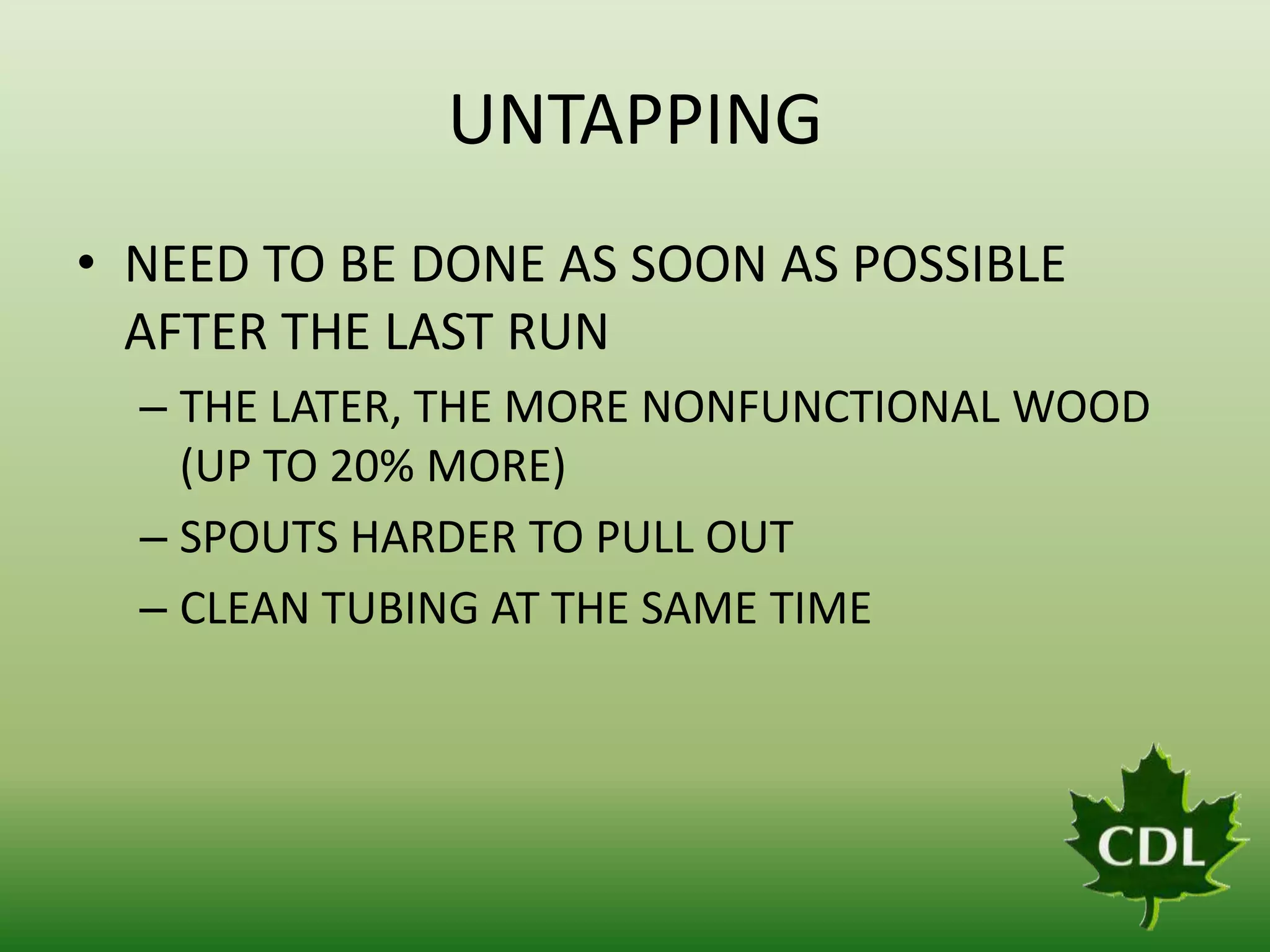

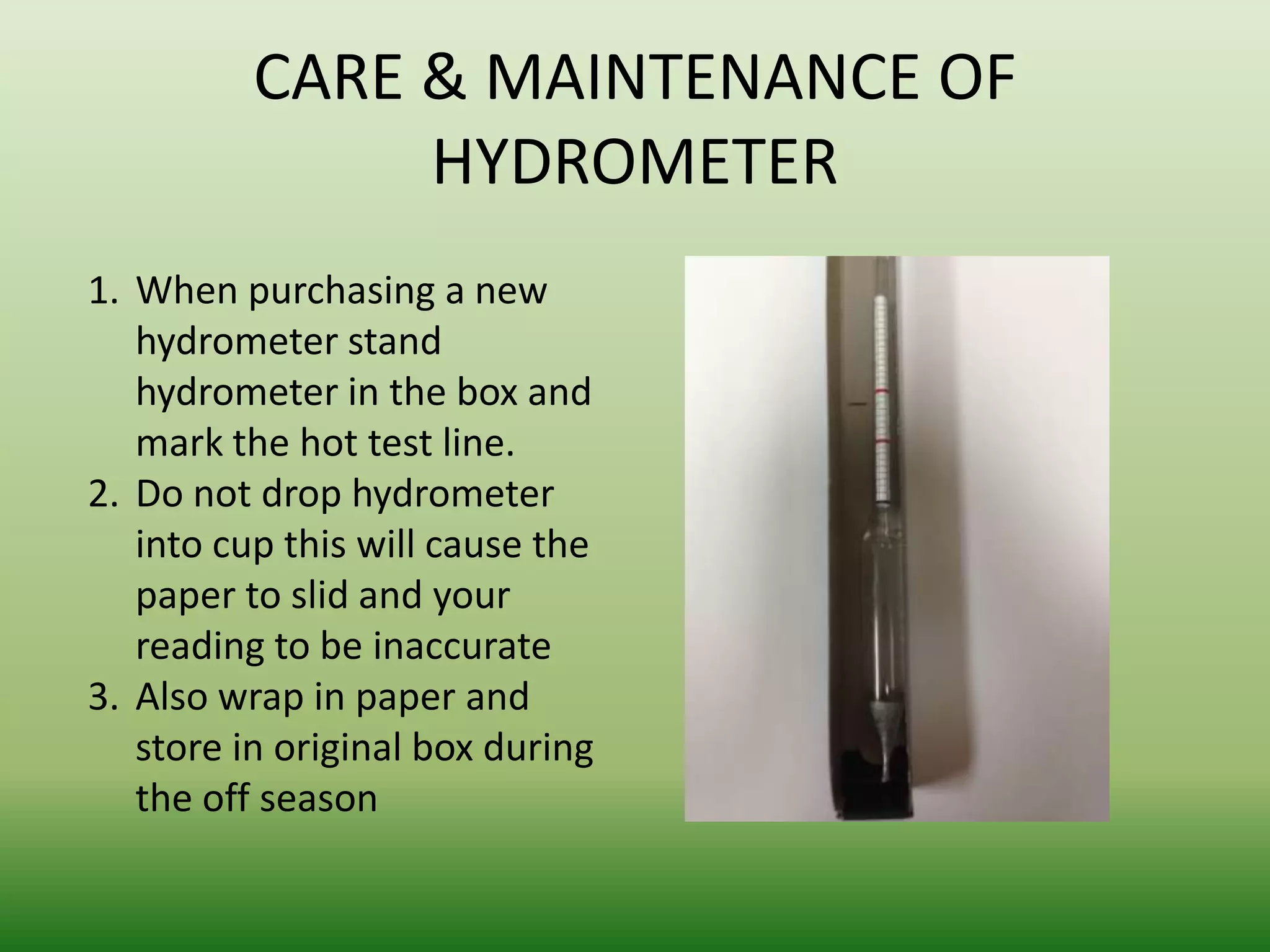

This document provides information on maple sugaring equipment and techniques for beginners. It discusses why maple sap is sweet due to the tree's photosynthesis process, and factors that influence sap flow such as freeze/thaw cycles, wind, pressure, snow coverage and past precipitation. It provides guidelines for tapping trees including the appropriate number of taps based on tree diameter, optimal tapping locations, and proper tapping depth. It also covers tools, spouts, collection equipment, boiling and testing syrup density with a hydrometer.