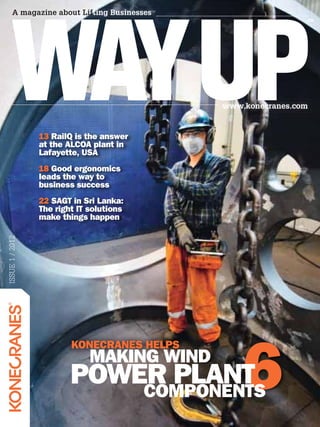

Way up magazine

- 1. A magazine about Lifting Businesses TM TM www.konecranes.com ISSUE 1 / 2012

- 2. Konecranes Editor’s note

- 3. January 2012 A service agreement for all 25 Konecranes cranes and the lift truck is a vital part to the operation of Vestas’ foundry in Xuzhou, East China.

- 4. Cranes take another step forward: From smart running TO SMART MAINTE “Look at the money we invest in R&D. It’s natural for Konecranes to be at the cutting edge of product and service development.”

- 5. Story by Patrick Humphreys Photo by Konecranes News around the world | January 2012 New vision NANCE New products How TRUCONNECT® works Major order

- 6. Story by Juha-Pekka Kervinen Photos by Lucas Schifres

- 7. The service team of Konecranes has participated in the Vestas China crane project from the start. An extensive service agreement guarantees that the lifting equipment vital to production operate without disturbances. the enormous foundry for a moment in Xuzhou, East China. Incandescent steel molten with cheap night electricity flows into the depths of a mold box in the dusk of dawn. According to a local museum, iron has been casted here since the times of the Qing dynasty. The timing is broad—the dynasty started in 1644 and ended in 1911. After a cooling period of two days, the Foundry Worker Huang Hai at Vestas Casting (Xu Zhou) Co., Ltd. factory opens the mold with his work mates. The steel has solidified into a wind turbine hub, almost two meters in diameter. A hub is the part where the rotor blades are attached.

- 8. The type designation of this hub is V , that is, the “At other foundries I have seen what a terrible diameter of the rotor blades will be meters (. feet). headache a crane that acts up can be. In no case do I want One can get an idea of the proportions of such a wind to experience such a thing again. That is why we have turbine when one sees the model power plant built next to concluded a service agreement for all our Konecranes the factory. Seen from a close distance, its rotor of only cranes and the Konecranes lift truck,” says Nygaard. meters (. feet) in diameter seems to fill the whole sky. The Vestas foundry in Xuzhou concluded a two-year Huang attaches the hub which weighs almost ten site service agreement with Konecranes in . The tons to the two hooks of the Konecranes crane moving agreement covers regular inspections and services, repairs at the ceiling level. It helps to turn the piece to different planned in advance and those done on needs basis, and positions for further processing. training. Moving around and also inside the hub, Huang Konecranes has a team of three service engineers, led controls the movements of the crane with the two by Ma Yong, at the foundry regularly. joysticks of the remote control which hangs from his belt. “The personnel here at the factory have one less In professional language, the crane has three worry. We guarantee that the cranes are available without directions of movement. Along the rails, or bridge; interruptions,” says Ma. crosswise, or trolley; and up/down, or hoist. The production capacity of the foundry is tons per week. Down time down The cranes are divided into three categories of The foundry in Xuzhou is owned by Vestas Wind Systems and it manufactures three wind power plant components. In addition to hubs, steel is molded into wind turbine foundations and bearing houses. The products manufactured in Xuzhou are delivered to the Vestas assembly plant in Tianjin, North China, or to other factories of the company in the USA and Europe. The Vestas Tianjin plant has over a hundred industrial cranes supplied by Konecranes. They also have a Konecranes service agreement. Vestas manufactures all wind power plant parts in China. The heaviest part of a power plant, that is, the steel tower, is usually purchased from a local steel structure manufacturer near the construction site. The cranes are a vital part of the operation of the foundry. Each product is molded according to an order. Meaning that someone is waiting for the timely arrival of every hub, foundation and bearing house at the assembly line. “The production must run without interruptions one hour after another /,” states Jan Nygaard, Technical Manager of the plant.

- 10. importance. For equipment most critical for production, there are detailed back up plans in case of disturbances. These cranes are also serviced and inspected more often than the others. Shanghai. The area is the wealthiest in the country. The service unit has more than contract customers in this Right there from the very start region. The service team of Konecranes has participated in the “More than half of the cranes serviced under the Vestas Xuzhou crane project from the start. agreement are delivered by Konecranes. The rest are “We want to find the best solution for the customer other makes. All the time a bigger part of the buyers of from the start. All information concerning the project, Konecranes cranes also want to make a service agreement the different lifting equipment and service, is shared,” with us,” says Yang Qi An. says Yang Qi An, Service Manager at the Konecranes The Vestas foundry is an important reference for Shanghai company. Konecranes. Potential crane customers are often brought “In Xuzhou, the service team worked together with the here to get to know Konecranes products and to hear customer’s project team already during the installation and about the operation of contract service directly from the commissioning of the cranes, thus building a relationship service customers. with the customer,” says Yang. “Vestas is one of our key customers worldwide and in The service team also trains the factory’s own China. It is good that our other customers can see here personnel to use the cranes. Not one crane has its how the contract service works,” says Yang. own operator, but almost all workers have obtained Xuzhou is located by the high-speed train track, the a crane license. Each of them can thus operate the construction of which was completed between Shanghai crane when needed. and Beijing just a few months ago. The train which Most cranes are equipped with a radio operated makes the trip in five hours has considerably improved remote controller. The operator can then use the the connections of Xuzhou to these two most important crane while walking on the factory floor. cities of China. The heaviest load to be lifted at a foundry is the mold box which weighs over a hundred tons. Safety comes first Uncompromising safety thinking is seen everywhere Ever more companies choose at the Vestas factory. Jan Nygaard informs the visitors the service agreement of safety instructions at the very start, for example, the The East China regional unit of Konecranes operates in meeting place in case of an alarm. the six eastern provinces of the country, located around Every person accessing the foundry must wear safety

- 11. shoes, protective clothing, hearing, breathing, and eye The RopeQ service, which inspects the wire ropes of protection, and a helmet. the crane, will also be taken into use soon. RopeQ will Many workers also wear other protective gear inspect the current condition of the wire ropes, also what according to their work tasks. The workers of the fettling one cannot see visually of the rope, using magnetic flux and grinding area have got a fresh air hose breathing leakage. apparatus which blows filtered air on their face, and a heavy duty cranes of the altogether cranes at working light on their helmets. the Vestas factory are made as special The safety status is told to a visitor right on the digital order just for this foundry. Their display in the reception lobby. “ days have passed speeds, safety properties and control since last industrial injury.” technique are the best possible for the An emergency generator is also part of the foundry special task of each. The ton forklift security system. It produces enough power for safely of the foundry is also delivered by emptying the furnace full of molten steel, and to run Konecranes. down the other processes for the duration of an outage. The Konecranes forklift complements the ceiling The electricity consumption of the foundry is three suspended cranes. It is used for moving casts to outdoor million kilowatt hours per year, half of which is spent on storage areas, or for lifting the casts onto storage shelves, the night-time melting of steel. The power required for or from shelves onto a loading vehicle platform for melting cannot be produced by the emergency generator. delivery to a customer. Together with the Vestas representatives, the service The shake out of sand molds is one challenging team of Konecranes is all the time developing new situation for a crane. The mold box weighing dozens of solutions for improving the safety and productivity of the tons is lowered onto a shaking surface to remove the sand cranes. used in the previous casting from the mold before the next casting. The handling of a shaking mold requires RailQ and RopeQ into use soon special properties of a crane. In Xuzhou, the new rail inspection system RailQ will Many heavy cranes come with a sway control soon be taken into use. In it, a robot traveling the rails of system. When lifted loads are accelerated or decelerated, the crane inspects the evenness, straightness, and other load swing is always present. The sway control system necessary parameters of the rails. dampens and stops the load swing automatically so that In China, industrial cranes must be inspected the operator does not have to do this manually. Through regularly. A crane which passes the inspection acceptably sway control load handling is more accurate and faster. will receive an operation license from the authorities for Thus sway control helps to improve the safety and two years at a time. productivity of the process.

- 12. Konecranes Agenda You have heard this before! he delivery reliability improves, efficiency increases, informatio delivery reliability li liability efficiency increases, information fficiency increases, information o becomes transparent, and m is left under the bottom line. nd more m A familiar speech from the ERP salespeople and suppliers of RP salespeople and supplie of alespeople e suppliers development services. The licenses cost millions and development and deployment work many times over. An improvement in results is indeed needed to make the projects profitable. It takes typically over a year before a working system can be tested—before that, the project team has presented thousands of pages of blue prints, scripts, requirement specifications, system landscapes... Many decision-makers start to lose faith while at the same time, they hear or read about epic failures of ERP projects. Tens of thousands of ERP projects have been made. Thousands of large ones too. A well implemented ERP system brings huge business benefits. Benefits the sales people promised. The benefits come especially from competent people, not only from the technical system. Thus the most critical success factor is personnel: developers and users. Investments must be made on developing competence. When the investment starts to look exaggerated, it is in fact only at a satisfactory level. First, the project team must learn to deliver a system that meets the requirements of the user. In such projects, the project team is unique and the experience increases by doing. The work must be chunked into smaller system entities which can be presented to the users, that way the team gets feedback for its work before the actual deployments. The team learns to deliver, and the feedback received is an important part of learning. When the development work is done in small pieces lasting a few months each, the latest version can be even rejected without endangering the entire investment. The users are faced with a two-fold learning challenge. First, they must learn to request features for processes and information systems which are under development. The initial requests often emerge from the ways the old systems are used. Second, they must learn to use and benefit from the capabilities provided by the new system. Learning through experience and the ability to apply the new into practice might develop slower if changes are big, but still these skills always develop! This you haven’t thought of before. The long-term benefits of a well implemented ERP system are even greater than what the sellers promised. Due to lack of experience, at the beginning one cannot even dream of all the benefits that will be reached as the competence accumulates! Therefore, concentrate on the development of the competence of the project team and users. Program Director

- 13. Story by Patrick Humphreys Photos by Lucas Schifres and Konecranes New Predictive equipment Maintenance The modern aluminum industry was discovered in 1888 by the Aluminum Company of America (ALCOA), which has been the world’s largest producer ever since. ALCOA Lafayette, in Moderni- Repairs zations and improve- turn, discovered Konecranes and RailQ in the last six years. ments Service life analyses and planning THE HIGHEST VALUE:

- 14. was getting some quotes for a crane rail replacement project,” says Vern Hendrickson, Project Engineer at ALCOA’s plant at Lafayette, Indiana. “Almost at the last moment, someone said ‘Try Konecranes’ and I said ‘Who?’” Hendrickson turned to Dave Timble, Key Accounts Manager at the nearby Konecranes service location in Indianapolis. “That’s when Dave and I first met. He came in with a bid that convinced me and we’ve been working together ever since.” Hearing the difference ALCOA in Lafayette is dealing with the problems of aging equipment. Some 60 percent of its production cranes are over 40 years old. RailQ was the answer, as Vern Hendrickson confirms. “We used to replace crane wheels fairly frequently. RailQ told us we needed to replace the crane rail in several bays and adjust the elevation. Since then we haven’t needed to replace any wheels. They don’t squeal on the rail as they did before.” Hendrickson’s Maintenance Manager Mark Mayes agrees: “After Konecranes started surveying the rails, squaring the cranes and doing the maintenance, we could hear the difference just by listening to the sound that the cranes make when they go down the rails." “In the past two years there have only been about three times when I’ve had to use my engineers to get a crane working again. Previously it was every day. We have hardly any unscheduled downtime.” Lifeline of the plant In Mark Mayes’s words, cranes are the lifeline of an ALCOA plant. “One of the first things I noticed, when I came here from the Chrysler Corporation in

- 15. Moderni- Repairs zations and improve- ments Service life analyses and planning 2007 was that when the cranes went down, we stopped moving.” “We have about 50 big overhead cranes on runways and a lot more small ones. They are how we move everything in shipping as well as production. We used to have a lot of plant-wide crane issues. We were constantly changing wheels, cables, and bearings.” When ALCOA Lafayette started working with Konecranes, the RailQ service was done manually. “When I heard that Konecranes was going to start using a robot I looked forward to it, and I’m glad it worked as well as it did. It eliminated somebody climbing down the bays to check spans and elevations. It has given us good results almost every time.” Surveys as a baseline Lafayette is a 2½ hour drive from Chicago down Route 52. The ALCOA plant there produces aluminum extrusions and dates back to the late 1930s. Vern Hendrickson believes that some of the problems with crane rail elevations have existed since that time. “Until Konecranes came along, we’d never had the detailed survey that we get now. We’ve strung a tape between people on each rail many times, but nothing had ever been done with the accuracy of the RailQ service.” As long as annual inspections continue, ALCOA can now expect crane wheels to last for a long time. “In any case I’ll be long gone,” Hendrickson laughs. Hendrickson is a believer in regular surveys. “I like to have a survey after we’ve done repair work so that we have a baseline. We can then compare this survey with the next survey and see if anything has changed.” Better lifting Konecranes now has two maintenance workers permanently on site at Lafayette. It has also helped with ALCOA operations, as Mark Mayes explains. “I’ve had them attend meetings where we sat down with the production people and explained the operations of a crane. Some operators even thought that if a crane was out of square, you could square it up by bumping it or using emergency stops.” “The operators now have a lot of faith in maintenance and in Konecranes. It’s a matter of safety as well as money. Management at ALCOA has its checkbooks open where safety is concerned.” “This is a union shop so you are always going to hear some comments about using outside workers instead of plant employees, but most of our guys wouldn’t want Konecranes to leave. And I’d be scared to operate without them.”

- 16. Story by Patrick Humphreys Photos by Gary Francis / www.velhot.com

- 17. Moderni- Repairs zations and improve- ments Service life analyses and planning onecranes has revolutionized crane and runway In Australia it makes a variety of steel products, mostly geometry surveys in Australia and New related to construction. Zealand, says James Dowe, General Manager Its plant at Wingfield, Adelaide, was one of the first for Konecranes services in Australia and New new customers when Konecranes was setting up an office Zealand. One of the leading steel companies in the in South Australia. region, BlueScope Steel, is certainly more than satisfied. “Which probably explains why they opened their “Since we introduced RailQ to Australia in March office directly across the road from us,” laughs Wingfield , we’ve used it in about inspections around Maintenance Manager Peter Terrison. the country. We’re measuring tolerances down to a few “RailQ’s performance was actually rather better than millimeters. In most cases, local standards demand that we had expected because the data was more detailed. variance between the rails has to be +/- mm,” says That first survey would probably have taken us a whole James Dowe. weekend using another system. With RailQ the whole “Although RailQ is advanced, pricing is very job was over and done with in about four hours,” competitive. We have a pretty sophisticated market here Terrison says. and our customers understand the value of accurate and “In fact it cost us no time at all because we scheduled reliable information. They want to make decisions based it in production downtime. Since then we’ve used RailQ on actual data rather than assumptions.” at two of our sites, testing rail alignment and crane “An important customer for us is BlueScope Steel structure. It isn’t significantly more expensive than a Ltd. We work with them in every state of Australia. traditional survey." At their Wingfield location in Adelaide, a relationship “In fact, it’s probably cheaper when you take labor of trust was formed between our South Australian and time into account. RailQ makes survey systems based Branch Manager John Jackman and BlueScope Steel’s on lasers or wires look antiquated and inaccurate." Maintenance Manager Peter Terrison,” says James “We’ve built up a very good working relationship with Dowe. the Konecranes people in Australia in the past three years. “When Bluescope Steel was looking to replace one We think their products are very professional. If we start of their production cranes at the Wingfield plant with a looking for more cranes in the future, I think they would high-performance SMARTON® crane, it also became the be the first company that we’d turn to.” very first SMARTON® crane that Konecranes delivered to Australia. Our specialist, Inspector Bron Ryzak conducted the RailQ survey to assess the suitability of the rails and whether they were properly aligned before the crane was installed–they weren’t. Certain columns needed to be lifted and a new rail was installed.” BlueScope Steel began life in as the renowned Broken Hill Proprietary Company of New South Wales. It later merged with two other pioneers of Australian steelmaking and today has operations throughout Asia.

- 18. Story by Marjatta Pietilä Illustration by Vesa Lehtimäki In mobile machines every piece of equipment is a user interface which either allows or prevents interaction between the user and the system. In improving human access, including both operating and maintenance of the machine, ergonomics plays an important role.

- 19. I is derived from the Greek words and—at the end of the day—the business success of the ergon and nomos. Ergon refers to work and nomos to laws. employer. According to the International Ergonomics Association, Easy access to the cabin, good visibility from the IEA, ergonomics is a scientific discipline concerned with cabin, suitable temperature, good air conditioning, proper the understanding of the interaction of humans and other lighting and minimized exposure to noise and vibration elements of the system and it focuses on maximizing human create the basic elements for good work conditions. But well-being and overall system performance. it is equally important that the cabin dimensions allow In designing cabins for mobile machines the for good working postures, easy access to the control domain of physical ergonomics within the discipline of equipment, computer displays and other instruments. ergonomics plays an important role. When the operator The design’s functionality depends on how easy it of the machine spends the whole day in the cabin, the is to learn to use, how quickly the user can efficiently work environment and work conditions perform the required tasks, how errors can be avoided have to be designed to allow maximum and recovered, and how much work satisfaction the performance for the operator. easy usability of the design allows. Under the domain of Ergonomics and usability go hand the cognitive ergonomics these issues have an effect on in hand with employee health, work the user’s experience of the workload, work stress, the satisfaction, efficiency, and productivity, command of professional skills and ability to perform on the level that satisfies both the user himself/herself and the employer. Scientific tools for designers “Today operators of mobile machines are keenly aware of how the physical configuration of the cabin affects their productivity and therefore their profit. Because of this, manufacturers desire to produce machines that are more comfortable and functional from a user standpoint. The ergonomics of a product can create a competitive advantage for a mobile machine manufacturer. Customer choices can be driven by their perception of the comfort and usability of a machine,” says Judy Vance, Joseph C. and Elizabeth A. Anderlik Professor of Engineering from the Virtual Applications Center at Iowa State University. Professors Vance’s research focuses on investigating the application of virtual reality techniques to engineering design. This method allows the designers to evaluate the design in a 3D space in order to generate the final design. “We use virtual reality to assess how operators interact with machines. This allows the designer to investigate multiple configurations in the virtual environment that would not be possible if each configuration needed to be built as a physical prototype. We use large screen stereo projection systems with optical position trackers and surround sound. Because of the large screen projection, we can present the operator station in full scale. The position

- 20. trackers allow us to track the user’s head position and modify the image as if he/she were looking in a certain direction. Position trackers also allow us to track the user’s hand so that he/she can interact with the workstation components,” Vance explains. According to Vance, some modifications, changes or new designs for improved ergonomics include features that are relatively easy and inexpensive to implement, but others require significant investments. The trade-off that the designers face is which features will be profitable in the end—whether the buyers seek profits by cutting costs or focus on improved productivity in a more sustainable way. Better designs by early customer engagement “Usually the mobile machine producers use external cabin designers and subcontractors for their cabin manufacture. Successful cabin design for mobile machines starts from recognizing the user needs. Usually an old cabin model is used as the basis for the design work. In such a case the client already knows the benefits and the disadvantages of the old model and can give clear instructions on the features that need to be improved,” tells Professor Asko Ellman from Tampere University of Technology, Finland. Ellman has a background in model based design of complex mechatronic systems and leads a group of researchers focusing on Virtual Design. The research ranges from the methods and technologies of Virtual Design to novel applications and their impact on practical business uses. Konecranes strives for “In our virtual reality laboratories located at the Seinäjoki University of Applied Sciences, Finland, we create virtual cabins. This method allows the customers and end-users to take part in the design work of the cabin almost from start. The cabins produced by three-dimensional visualization, are of the natural size and nearly identical to real cabins, and they give the customers and end-user a clear picture of the cabin and its functionality,” Ellman explains. According to Ellman the customer focused design allows the developer to get a user experience for example on the visibility from the cabin, control function, ergonomics, and safety at an early stage of the design work, when the shortcomings are still easy to correct. The virtual testing tool increases customer satisfaction and reduces the time required for the development phase. When the virtual model satisfies all parties a prototype can be produced for physical evaluation and testing. “Product modifications are often needed for different markets. Preferences in Africa may differ from those in Europe. For example in markets with high illiteracy rate, symbols are preferred over writing,” Ellman points out.

- 21. Judy M. Vance Asko Ellman better ergonomics

- 22. Story by Mauri Kaarre Photos by Mikko Huotari

- 23. SAGT’S SECRET OF SUCCESS IS A HIGHLY ACCURATE CONTAINER YARD High productivity and efficiency backed by Konecranes’ container positioning system helped South Asia Gateway Terminals (SAGT) in Sri Lanka to handle 1.9 million TEUs in 2010. An excellent figure for a terminal with a designed capacity of 1.1 million TEUs, don’t you agree?

- 24. t is a hot and humid August morning, approaching eight. The monsoon season with the rain is far behind. As a distant memory of it, partly cloudy weather is forecast for Colombo, the usually oh so sunny commercial capital of Sri Lanka (formerly known as Ceylon before 1972) Colombo, only +28 degrees Celsius. The multitude of people walking to work, and the tricycle tuk tuk taxis which weave their way through lines of buses are typical of the morning rush near the World Trade Center in the immediate vicinity of Port of Colombo. The Indian Ocean and the sea of cranes rising at the container freight terminal in the harbor loom in the horizon. Some of the crane booms are up in accordance with the safety policies, as if to remind the vessels that they can come here. Some of the crane booms are down, meaning that the cranes are at work loading and unloading vessels. The container freight terminal never sleeps. The Port of Colombo with its state owned Jaya and Unity Container Terminals and Sri Lankas’s first modern private container terminal, South Asia Gateway Terminals (SAGT), is rated amongst the top container ports in the world. SAGT took over the historic Queen Elizabeth Quay in the Port of Colombo in 1999 on a 30-year Build-Own-Transfer (BOT) concession. Sri Lanka, an island nation in South Asia, located about 31 kilometers (19.3 miles) off the southern coast of India, is a strategically brilliant naval link on the main East-West shipping route, linking the Far East with Africa, Europe, and the East Coast of the US, providing ideal connections to the trade in the Indian sub-continent. Famous for the production and export of tea, coconuts and rubber, Sri Lanka boasts a progressive and modern industrial economy and the highest per capita income in South Asia. The natural beauty of Sri Lanka’s tropical forests, beaches and landscape, as well as its rich cultural heritage, boost the island state’s transformation into an ever more popular tourist attraction. Especially after the civil war in the country ended a couple of years ago. IT makes things happen According to Upul Jinadasa, SAGT’s General Manager, Information Technology, his role is to identify the right technology and solutions. After the identifying part he implements and supports the chosen conclusions. “Our main focus as a port is to maintain world class service levels. The right IT solutions will play an important role in making things happen,” Jinadasa says. “Earlier we had 28 RTGs that came with PDS based on transponders. Basically, the system didn’t work no matter how we tried to fix it. We needed a good solution

- 25. fast. So we turned to Konecranes and had their container positioning information system installed in one of our RTGs as a pilot test in late 2006. It worked perfectly. In 2007 we installed their system in our 31 RTGs and 70 trucks.” Jinadasa is very pleased with Konecranes’ system. “Thanks to it our container inventory is very accurate. If there are problems with the location of containers both the planning and productivity go wrong. And you cannot have a successful terminal without proper planning.” “We have four critical factors that build our success. We have world class systems, modern equipment in IT and engineering, the best processes, and last but not least, a very good staff,” Jinadasa says. congestion in the terminal area allowing a smooth and Accurate records rule efficient operation. This is a compact terminal so we The accurate container records, once again, play a key closely monitor everything and make sure we get the role also for Laksiri Nonis, SAGT’s General Manager maximum utilization of the container yard,” says Nonis. Operations. “It not only makes a huge difference to the customer “My goal is to minimize the traffic and prevent any but also to us if a box is staying in the yard longer than

- 26. the box in a wrong place. “Then the whistles are blown, that is, the system sounds an alarm, which is transmitted to operators, and the guy in the control tower. The result: 100 percent accurate inventory of the container yard,” Sampo explains. According to him, the operation of the Konecranes IT solution is ingenious in its simplicity. ”The crane operator stacks the container and leaves it is supposed to. So, the sooner we get the transshipment it in place. The system then intakes a signal from the connection on its way, the better.” crane PLC (twistlock activity) and satellites. Based on “Containers are stored in the yard by linking the the information the container location’s X,Y and Z container number to the yard location and we are very coordinates are defined and reported directly to the TOS much dependent on that information. We cannot run software database.” without technology, so we wanted to make sure we got “And what’s best is that the crane operator does not a reliable system with a good back-up. If everything need to do anything, he can fully concentrate on his stopped, just for a few minutes because of power failure container handling tasks, because reporting to TOS is or so, it would have a big impact on the terminal’s fully automatic. So this is also an important safety issue. efficiency.” In the case of SAGT, we installed the system in other manufacturers’ machines–our system is usable in all types Intelligence instead of iron of container handling equipment.” Mikko Sampo, General Manager, Konecranes YardIT, The view from Crane Operator Viraj Priyadarshana’s has 27 years background in machine automation and crane cabin high up at 40 meters (131.2 feet) is just service. He oversaw the system deal and says majestic. Air conditioning blows smoothly and the that terminals nowadays tend to increase Indian Ocean is wide open. Not bad, some people really productivity and efficiency by purchasing work at the top. IT solutions. “A very easy handling system. Now I can just “Now we focus more on intelligence,” concentrate on my real work and focus on achieving Sampo states. the productivity targets,” says Priyadarshana who’s been “Another equally important thing is handling containers for four years at SAGT. that with the help of our remote connection service team based in Hyvinkää, Finland, Transshipment is the name the support agreement made with SAGT of the business and its engineering team at the site, and Erwin Haaze, CEO of SAGT says their business consists with the local spare part arrangement we of 80 percent of transshipment container traffic with can guarantee the functioning of the system around 70 percent coming from Indian origin. The under all conditions,” Sampo says. terminal’s volumes have been increasing steadily during And just to make everything perfect, all the last years. the positions are updated to the Terminal “We are fully booked berth wise. We have ten cranes Operation System (TOS) database even if on a 940-meter berth and we hit almost 2 million TEUs the crane operator accidentally tries to put in 2010, and 2011 was the best year ever. It has been a tremendous performance by the SAGT team and shows the commitment and dedication of our staff as well as the potential that is available in Sri Lanka! This year

- 27. we are also doing well, but the closer you get to the maximum throughput, the more challenging it is,” Haaze says. The statistics are impressive. From 2006 to 2010, with exeption of the year 2009 in which SAGT still managed to achieve a marginal increase in throughput (1.3 percent) despite the economic turmoil, SAGT has realized year to year increases of 15.8 percent, 11.6 percent and 12.6 percent, doubling the throughput achieved in 2005. Productivity wise the trend showed similar developments leading to productivity levels averaging 27 crane moves per hour on all vessels including the smaller feeders with regularly hitting 30+ crane moves per hour. Haaze says also the busier SAGT gets, the more they need to focus on strategies and make sure that all the primary structures are in order. “Installing Konecranes’ container positioning system in our cranes was one of those good strategic decisions. We will also have two new cranes with further outreach and higher lifting capacity by the end of this year so that we can work more efficiently on the bigger vessels. It’s all about the customer service,” Haaze says. Gaining transshipment hub status CEO Haaze’s mission is simply that SAGT need to perform in a way that it remains the preferred number one terminal in South Asia. “To achieve this, reliability is the key. When our customers come to the terminal they already know they can leave in a reasonable time period which we indicate to them right from the start.” “Geographically the Port of Colombo has an advantage over the other ports for setting up a real transhipment hub in the area. We have everything here, including all the big shipping lines and feeder network. We also have an excellent stability and good labor conditions.” Haaze also adds that SAGT is carefully making the whole platform ready in case SAGT decides to make use of any expansion opportunities in the future. As part of the Colombo South Harbor Development Project initiated by the Sri Lankan Ports Authority, the construction of the new South Harbor adjacent to the Port of Colombo is currently underway in order to meet the increasing need for greater capacity. The new facility will provide four more container terminals and can accommodate the next generation of container vessels.

- 29. Story and photos by Mikko Huotari In the harbor with leafy mango trees

- 30. Konecranes Safety, reliability and productivity to ports with RTG TESTING

- 31. #1/12

- 32. Konecranes Introducing the new Konecranes cabin Superior workspace for crane drivers

- 33. #1/12

- 34. Story and photos by Vesa Eskola

- 35. What on earth does Konecranes have in common with a vineyard in Spain? Amid the Juan Domingo Tarrega got very interested. gently sloping hills–covered by orange trees, grapevines, “After that it was quite simple really. We sat down and centuries old olive trees–is nested a very modern with Konecranes representative, David Caro, and saw vinery, SAT Mas de Rander. The ultra modern design of almost immediately that we had the perfect solution.” the production buildings stands out. He also agrees they were a bit lucky. The 20 hectare vineyard is run by Juan Domingo “The truth is, we were very lucky. All the people Tàrrega. The whole production is organic. Several involved did their best to make the most out of our grape varieties are used: Cabernet Sauvignon, Grenache, traditional cellar with a unique, subtle, and modern Merlot, some Muscats and Syrah. Wine is sold of course touch.” in Spain but also exported to other European countries. Well, the settings certainly aren’t from a Soon also the Chinese and Japanese wine lovers will be traditional vineyard. The two ton crane is also able to enjoy the red nectar from Mas de Rander. very busy during the wine season. We are standing with Juan Domingo Tarrega under a “The crane helps us to perform high two ton crane. Not a typical tool you would expect to see precision tasks safely and reliably. It also helps in a vineyard. us to work faster. The crane is actually one of “We use the crane to move grapes from the grape the mechanical tools we use the most. Because mill to the fermentation tanks. This helps us give our of the crane we don’t have to use expensive wine a special character. Traditionally, this task is done by conveyor belts. In our experience, we think that pumps, but that way most of the grapes get broken. We with the help of the crane we are one of the do things a bit differently.” most advanced vineries in Spain.” The idea might be an original one, but everything SAT Mas de Rander produces about also came together almost by accident. 250,000 bottles of wine annually. The majority “The engineer in charge of those wines are reds (225,000 of the project asked for bottles), the rest are sweet wines offers from different crane and a special mixture known as manufacturers. When he had “mistela”, where a little bit of all the information he came brandy is added to the wine. The to me: ‘One proposal, due result is a kind of Sherry. to its design, could save you a lot of money. It wouldn’t just do the required tasks, it would also help you to erect the cellar, tanks, and platforms’.”