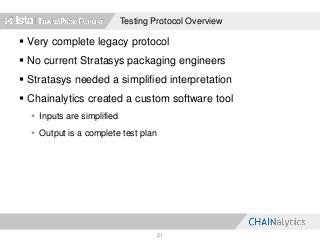

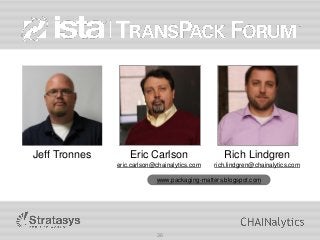

The Supply Chain Packaging Optimization team at Chainalytics presented "The Story of Mojo: Building a Packaging Focus into Product Design" at ISTA TransPack Forum 2014.

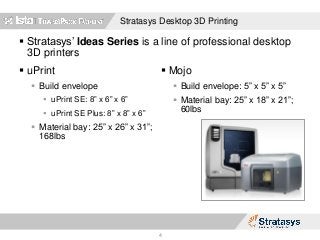

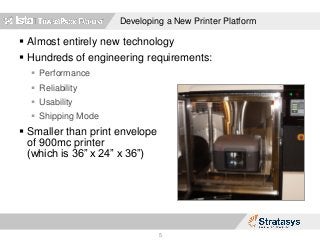

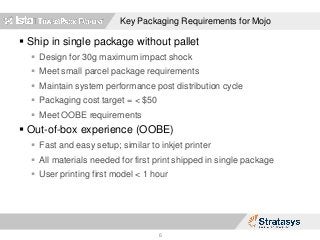

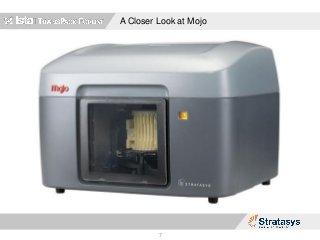

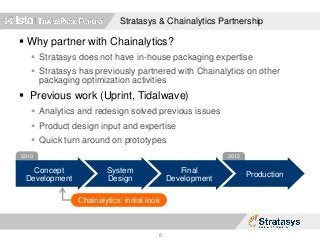

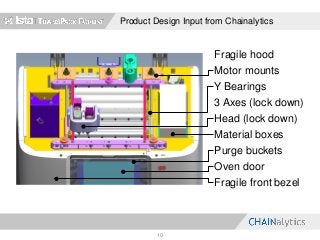

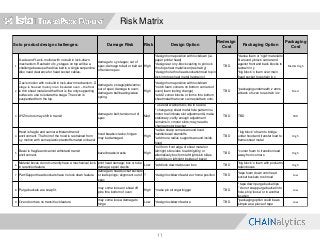

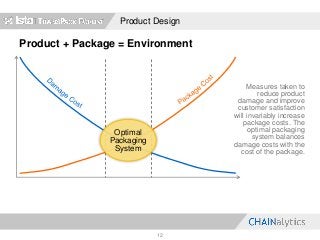

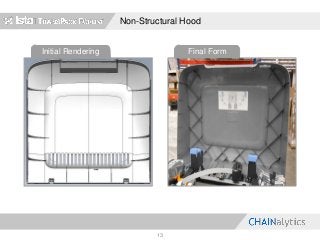

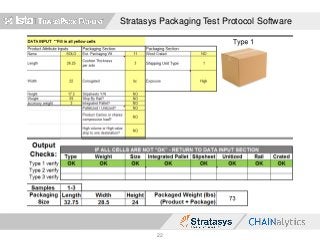

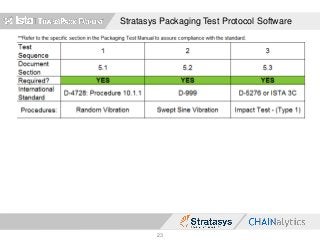

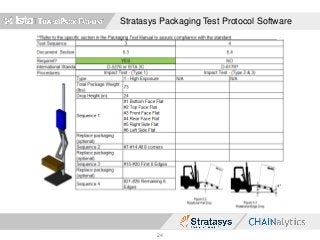

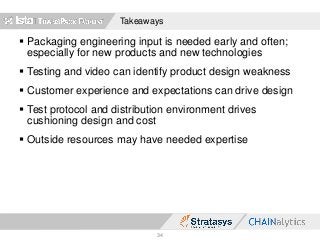

Companies driven by innovation are most effective when stakeholder input is incorporated early and often. This is especially true when it comes to packaging engineering and supply chain management. Stratasys, a leading manufacturer of 3D printing equipment and materials, embraced this thinking when it partnered with Chainalytics, a global leader in packaging and supply chain consulting, to design its new 3D desktop printer, Mojo.

To learn more on how to optimize your packaging or product design while keeping your supply chain needs and distribution requirements at the forefront of the project, contact our packaging optimization specialists at packaging@chainalytics.com or simply call +1 (612) 252-1830