Vikas Mane cv

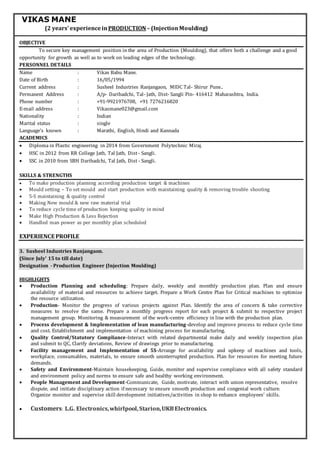

- 1. VIKAS MANE (2 years’ experienceinPRODUCTION– (InjectionMoulding) OBJECTIVE To secure key management position in the area of Production (Moulding), that offers both a challenge and a good opportunity for growth as well as to work on leading edges of the technology. PERSONNEL DETAILS Name : Vikas Babu Mane. Date of Birth : 16/05/1994 Current address : Susheel Industries Ranjangaon, MIDC Tal- Shirur Pune.. Permanent Address : A/p- Daribadchi, Tal- Jath, Dist- Sangli Pin- 416412 Maharashtra, India. Phone number : +91-9921976708, +91 7276216820 E-mail address : Vikasmane023@gmail.com Nationality : Indian Marital status : single Language’s known : Marathi, English, Hindi and Kannada ACADEMICS Diploma in Plastic engineering in 2014 from Government Polytechnic Miraj. HSC in 2012 from RR College Jath, Tal Jath, Dist- Sangli. SSC in 2010 from SBH Daribadchi, Tal Jath, Dist - Sangli. SKILLS & STRENGTHS To make production planning according production target & machines Mould setting – To set mould and start production with maintaining quality & removing trouble shooting 5-S maintaining & quality control Making New mould & new raw material trial To reduce cycle time of production keeping quality in mind Make High Production & Less Rejection Handled man power as per monthly plan scheduled EXPERIENCE PROFILE 3. Susheel Industries Ranjangaon. (Since July’ 15 to till date) Designation - Production Engineer (Injection Moulding) HIGHLIGHTS Production Planning and scheduling: Prepare daily, weekly and monthly production plan. Plan and ensure availability of material and resources to achieve target. Prepare a Work Centre Plan for Critical machines to optimize the resource utilization. Production- Monitor the progress of various projects against Plan. Identify the area of concern & take corrective measures to resolve the same. Prepare a monthly progress report for each project & submit to respective project management group. Monitoring & measurement of the work-centre efficiency in line with the production plan. Process development & Implementation of lean manufacturing-develop and improve process to reduce cycle time and cost. Establishment and implementation of machining process for manufacturing. Quality Control/Statutory Compliance-Interact with related departmental make daily and weekly inspection plan and submit to QC, Clarify deviations, Review of drawings prior to manufacturing. Facility management and Implementation of 5S-Arrange for availability and upkeep of machines and tools, workplace, consumables, materials, to ensure smooth uninterrupted production. Plan for resources for meeting future demands. Safety and Environment-Maintain housekeeping, Guide, monitor and supervise compliance with all safety standard and environment policy and norms to ensure safe and healthy working environment. People Management and Development-Communicate, Guide, motivate, interact with union representative, resolve dispute, and initiate disciplinary action if necessary to ensure smooth production and congenial work culture. Organize monitor and supervise skill development initiatives/activities in shop to enhance employees’ skills. Customers: L.G. Electronics,whirlpool,Starion,UKBElectronics.

- 2. MACHINE L&T 100, 140, 150, 250, 325, 350 Ton. Mitsubishi 350, 450Ton. Godrej Enaviva 500 Ton. Haitian 600 Ton. Feromatic 650 Ton. 2. Plastic Omnium Auto Exteriors Pvt Ltd., (Chakan) Pune, Maharashtra, India (Since May’14 to May’15) Designation – Trainee Technician - PRODUCTION (Injection Moulding) HIGHLIGHTS It is MNC Company from France. It is manufacturer’s auto exterior parts, Such as front & Rear bumper, Fender. Customers: General Motors,M&M,VW,SKODA. It is also paint moulded parts. First’ in India to introduce Plastic Fenders in 2011. MACHINE Lenfa 3000 Ton. Feromatic 3200 Ton. TRAININGS ATTENDED Attended various training schedules on: Injection Machine Inspection Method • 5s Mould management • Process Optimization DECLARATION I hereby declare that information furnished above is true to the best of my knowledge and belief on me. Date : - Place : - VIKAS BABU MANE