YALE G813 GDP80VX LIFT TRUCK Service Repair Manual

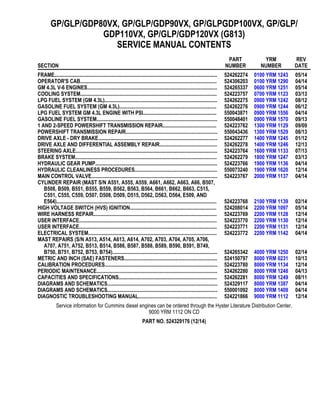

- 1. GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLPGDP100VX, GP/GLP/ GDP110VX, GP/GLP/GDP120VX (G813) SERVICE MANUAL CONTENTS SECTION PART NUMBER YRM NUMBER REV DATE FRAME............................................................................................................................ 524262274 0100 YRM 1243 05/14 OPERATOR'S CAB........................................................................................................ 524306203 0100 YRM 1290 04/14 GM 4.3L V-6 ENGINES................................................................................................... 524265337 0600 YRM 1251 05/14 COOLING SYSTEM........................................................................................................ 524223757 0700 YRM 1123 03/13 LPG FUEL SYSTEM (GM 4.3L)...................................................................................... 524262275 0900 YRM 1242 08/12 GASOLINE FUEL SYSTEM (GM 4.3L).......................................................................... 524262276 0900 YRM 1244 06/12 LPG FUEL SYSTEM GM 4.3L ENGINE WITH PSI........................................................ 550043871 0900 YRM 1556 04/14 GASOLINE FUEL SYSTEM............................................................................................ 550048401 0900 YRM 1570 09/13 1 AND 2-SPEED POWERSHIFT TRANSMISSION REPAIR......................................... 524223762 1300 YRM 1129 09/09 POWERSHIFT TRANSMISSION REPAIR...................................................................... 550043436 1300 YRM 1529 08/13 DRIVE AXLE - DRY BRAKE........................................................................................... 524262277 1400 YRM 1245 01/12 DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR............................................ 524262278 1400 YRM 1246 12/13 STEERING AXLE............................................................................................................ 524223764 1600 YRM 1133 07/13 BRAKE SYSTEM............................................................................................................ 524262279 1800 YRM 1247 03/13 HYDRAULIC GEAR PUMP............................................................................................. 524223766 1900 YRM 1136 04/14 HYDRAULIC CLEANLINESS PROCEDURES............................................................... 550073240 1900 YRM 1620 12/14 MAIN CONTROL VALVE................................................................................................ 524223767 2000 YRM 1137 04/14 CYLINDER REPAIR (MAST S/N A551, A555, A559, A661, A662, A663, A66, B507, B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515, C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, AND E564).......................................................................................................................... 524223768 2100 YRM 1139 02/14 HIGH VOLTAGE SWITCH (HVS) IGNITION.................................................................. 524208014 2200 YRM 1097 05/14 WIRE HARNESS REPAIR.............................................................................................. 524223769 2200 YRM 1128 12/14 USER INTERFACE......................................................................................................... 524223770 2200 YRM 1130 12/14 USER INTERFACE......................................................................................................... 524223771 2200 YRM 1131 12/14 ELECTRICAL SYSTEM.................................................................................................. 524223772 2200 YRM 1142 04/14 MAST REPAIRS (S/N A513, A514, A613, A614, A702, A703, A704, A705, A706, A707, A751, A752, B513, B514, B586, B587, B588, B589, B590, B591, B749, B750, B751, B752, B753, B754)................................................................................ 524265342 4000 YRM 1250 02/14 METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13 CALIBRATION PROCEDURES...................................................................................... 524223780 8000 YRM 1134 12/14 PERIODIC MAINTENANCE............................................................................................ 524262280 8000 YRM 1248 04/13 CAPACITIES AND SPECIFICATIONS........................................................................... 524262281 8000 YRM 1249 08/11 DIAGRAMS AND SCHEMATICS.................................................................................... 524329117 8000 YRM 1387 04/14 DIAGRAMS AND SCHEMATICS.................................................................................... 550001092 8000 YRM 1409 04/14 DIAGNOSTIC TROUBLESHOOTING MANUAL............................................................ 524221866 9000 YRM 1112 12/14 Service information for Cummins diesel engines can be ordered through the Hyster Literature Distribution Center. 9000 YRM 1112 ON CD PART NO. 524329176 (12/14)

- 2. SAFETY PRECAUTIONS MAINTENANCE AND REPAIR • The Service Manuals are updated on a regular basis, but may not reflect recent design changes to the product. Updated technical service information may be available from your local authorized Yale® dealer. Service Manuals provide general guidelines for maintenance and service and are intended for use by trained and experienced techni- cians. Failure to properly maintain equipment or to follow instructions contained in the Service Manual could result in damage to the products, personal injury, property damage or death. • When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load. • Do not lift heavy parts by hand, use a lifting mechanism. • Wear safety glasses. • DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Discon- nect the battery ground cable on internal combustion lift trucks. • Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section. • Keep the unit clean and the working area clean and orderly. • Use the correct tools for the job. • Keep the tools clean and in good condition. • Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. • Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts. • Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs. • Be sure to follow the WARNING and CAUTION notes in the instructions. • Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems. • Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated. NOTE: The following symbols and words indicate safety information in this manual: WARNING Indicates a hazardous situation which, if not avoided, could result in death or serious injury. CAUTION Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury and property damage. On the lift truck, the WARNING symbol and word are on orange background. The CAUTION symbol and word are on yellow background.

- 3. Cooling System Table of Contents TABLE OF CONTENTS General................................................................................................................................................................ 1 Cooling System Checks ...................................................................................................................................... 1 Exhaust Leaks Into Cooling System ............................................................................................................... 1 Water Flow Restrictions in Radiator................................................................................................................ 1 Radiator Hoses ............................................................................................................................................... 1 Water Pump .................................................................................................................................................... 1 Flushing the Cooling System............................................................................................................................... 2 Cooling System, Clean.................................................................................................................................... 2 Radiator Replacement......................................................................................................................................... 3 Radiator, Remove for Lift Trucks Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875); GLP/GDP20-25LX (GLP/GDP050LX) (A974); GLC40, 45, 55VX, GLC55SVX, (GC/GLC080, 100, 120VX, GC/GLC080, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS) (E818, F818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) .............................................................................................................................. 3 Radiator, Remove for Lift Trucks Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC050LX (A967) and GLP/GDP20-25LX (GLP/GDP050LX) (A974) Equipped with Oil Cooler................................................................................................................................. 19 Radiator, Remove for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) .................................................................................................................................................... 21 Radiator, Remove for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) ....................................................... 24 Radiator, Install for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875); GLP/GDP20-25LX (GLP/GDP050LX) (A974); GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) .............................................................................................................................. 29 Radiator, Install for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC050LX (A967) and GLP/GDP20-25LX (GLP/GDP050LX) (A974) Equipped with Oil Cooler................................................................................................................................. 33 Radiator, Install for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) .................................................................................................................................................... 34 Radiator, Install for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) ....................................................... 37 Fan Assembly Replacement................................................................................................................................ 47 Fan Removal ................................................................................................................................................... 47 Inspect............................................................................................................................................................. 62 Fan Installation................................................................................................................................................ 62 ©2013 Yale Materials Handling Corp. i

- 4. Table of Contents Cooling System TABLE OF CONTENTS (Continued) This section is for the following models: GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX [C809]; GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) [C810]; GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) [A910]; GLC050LX [A967]; GLP/GDP20-35VX (GP/GLP/GDP040-070VX) [B875]; GLP/GDP20-25LX (GLP/GDP050LX) [A974]; GLC40, 45, 55VX; GLC55SVX (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) [E818, F818]; GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) [F813, G813, H813, J813]; GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) [C879, D879, E879, F879]; GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) [C878, D878, E878]; GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) [A909, B909] ii

- 5. 700 YRM 1123 Cooling System Checks General This section contains the repair and replacement in- structions for the radiator, coolant level sensor, fan assembly (pusher type), fan shroud, coolant hoses, coolant recovery bottle, and optional debris screen. Cooling System Checks EXHAUST LEAKS INTO COOLING SYSTEM WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. Contact with these parts can cause serious injury. To check for exhaust leaks into the cooling system, use a Combustion Leak Test Kit for this purpose. Follow the manufacturer’s instructions when doing the test. WATER FLOW RESTRICTIONS IN RADIATOR WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. Contact with these parts can cause serious injury. To check for water flow restrictions in the radiator, run engine until it is warm. WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. Shut engine OFF and feel the radiator. The tempera- ture must be even across the radiator. (The radiator will be hotter near the top radiator hose.) Cold spots on ra- diator indicate restrictions. If radiator has leaks, either replace the radiator or have it repaired by trained personnel. RADIATOR HOSES WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. Inspect all radiator hoses. If they feel spongy or have visible cracks, replace hoses. WATER PUMP WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. Contact with these parts can cause serious injury. WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Run engine until it is warm. Check the operation of wa- ter pump by holding the top radiator hose. If the pump is operating, there will be pressure surges in the hose. Check for leaks around the timing belt cover near the base of the oil pump. Check the weep hole where coolant that leaks past the water pump seal can be drained before reaching the water pump bearings. If there is a drip, check the pump shaft seal and water pump. Replacement of the pump shaft seal or water pump may be necessary. For repair procedures for the GM 2.4L water pump, refer to the section GM Engine Repair, GM 2.4 Liter Engine 600 YRM 1121. For repair procedures for the Mazda FE and F2 water pump, refer to the section Mazda Engine, FE and F2 600 YRM 1122. For replacement procedures for the Yanmar 2.6L and 3.3L water pump, refer to the section Yanmar Diesel Engines, 2.6L, 3.0L and 3.3L 600 YRM 1205. 1

- 6. Flushing the Cooling System 700 YRM 1123 For replacement procedures for the GM 4.3L water pump, refer to the section GM Engines, 4.3 Liter V-6 600 YRM 1251. For replacement procedures for the GM 5.7L water pump, refer to the section GM Engines, 5.7 Liter V-8 LPG 600 YRM 1432. For replacement procedures for the Kubota water pump, refer to the section • Kubota Diesel 3.8L Engines 600 YRM 1557 • Kubota Diesel 3.6L Engine 600 YRM 1579 • Kubota Diesel 3.8L Engines, with Diesel Particu- late Filter (DPF) 600 YRM 1590 For replacement procedures for the Cummins 4.5L and QSB 3.3L water pump, contact your local Yale dealer or see Yale Axcess Online. Flushing the Cooling System COOLING SYSTEM, CLEAN WARNING Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. WARNING The radiator fins on the radiator are very sharp and can cause serious injury. Wear gloves while check- ing the radiator fins. 1. Check radiator fins. Clean exterior of radiator with compressed air or water as needed. WARNING DO NOT remove the radiator cap from the radiator when the engine is hot. When the radiator cap is removed, the pressure is released from the system. If the system is hot, the steam and boiling coolant can cause burns. WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. 2. Drain cooling system. Fill cooling system with clean water. See sections below for more information: • Radiator, Remove for Lift Trucks Mod- els GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875); GLP/GDP20-25LX (GLP/GDP050LX) (A974); GLC40, 45, 55VX, GLC55SVX, (GC/GLC080, 100, 120VX, GC/GLC080, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS) (E818, F818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) • Radiator, Remove for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) • Radiator, Remove for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLP/GDP80VX, GLP/ GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 3. Install radiator cap. Run engine until top radiator hose is hot. Stop engine and let engine cool. 4. Drain water from radiator. If water is dirty, fill sys- tem with water and repeat procedure until water is clean. 2

- 7. 700 YRM 1123 Radiator Replacement CAUTION Follow the manufacturer’s instructions when using a chemical radiator cleaner. 5. If water does not clean system, use a chemical ra- diator cleaner. CAUTION Follow the manufacturer’s instructions when using special equipment to reverse clean the radiator. 6. If radiator or cooling system is very dirty or has a restriction, use reverse cleaning method. This method uses water pressure to force water through radiator in opposite direction of normal flow. CAUTION Additives may damage the cooling system. Before using additives, contact your local Yale dealer. 7. Fill cooling system with ethylene glycol boron-free antifreeze. Purchase a pre-diluted 50/50 solution; or mix 50 percent concentrate with 50% distilled or deionized water. The 50/50 mixture will pro- tect cooling system to 37°C ( 35°F). Add coolant as necessary to keep level between the ADD and FULL marks on the reservoir. Radiator Replacement RADIATOR, REMOVE FOR LIFT TRUCKS MODELS GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875); GLP/GDP20-25LX (GLP/GDP050LX) (A974); GLC40, 45, 55VX, GLC55SVX, (GC/GLC080, 100, 120VX, GC/GLC080, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS) (E818, F818) AND GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. 1. Turn OFF truck. 2. Remove the hood and seat combination. See Frame 100 YRM 1120 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) See Frame 100 YRM 1243 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) See Frame 100 YRM 1423 for lift truck models • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) WARNING Always disconnect the cable at the negative termi- nal first. Install a tag on the battery terminals so that no one connects the cables on the terminals. 3. Disconnect the negative battery cable. 4. Disconnect the positive battery cable. 3

- 8. Radiator Replacement 700 YRM 1123 WARNING DO NOT remove the radiator cap from the radiator when the engine is hot. When the radiator cap is removed, the pressure is released from the system. If the system is hot, the steam and boiling coolant can cause burns. 5. Let coolant cool to ambient temperature. Place a drain pan with a capacity greater than the capacity of the cooling system under radiator. Remove radi- ator cap. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. 6. Open the drain plug or loosen hose clamp and dis- connect the lower hose. 7. Lift trucks equipped with a Cummins QSB 3.3L diesel engine: Loosen clamps and disconnect the charge air cooler hoses from charge air cooler. See Figure 6. 8. Lift trucks equipped with a Kubota 3.8L diesel en- gine: Loosen clamps and disconnect transmission cooler hoses from transmission cooler. See Fig- ure 8. 9. Once coolant is drained from engine, loosen hose clamps and disconnect coolant hoses from radiator. Cap radiator hoses. 10. Loosen hose clamp and disconnect hose from reservoir and remove reservoir. See Figure 1 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809 • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) • GLC050LX (A967) • GLP20-25LX (GLP050LX) (A974) See Figure 2 or Figure 3 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) See Figure 4 or Figure 5 for lift truck models • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813) See Figure 6 for lift truck models below equipped with a Cummins QSB 3.3L diesel engine • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (G813 • GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (D879) See Figure 7 for lift truck models below equipped with Yanmar 2.6L diesel engine • GDP20-25LX (GDP050LX) (A974) See Figure 8 for lift truck models below equipped with a Kubota 3.8L diesel engine • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (H813, J813) 11. Remove battery and battery tray. 12. If equipped, disconnect electrical connector to the coolant level sensor. NOTE: For Mazda LPG engine, the LPG converter bracket needs to be moved for clearance of radiator. 13. Remove screws and washers from the shroud and move shroud out of the way. 14. Place radiator guard shield between radiator and fan so damage to radiator does not occur during fan removal. 15. Remove fan, fan spacer, and pulley. 16. Remove radiator guard shield. 17. Remove capscrews and upper radiator bracket. See Figure 1 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809 • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) 4

- 9. 700 YRM 1123 Radiator Replacement • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) • GLC050LX (A967) • GLP20-25LX (GLP050LX) (A974) See Figure 2 or Figure 3 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) See Figure 4 or Figure 5 for lift truck models • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813) See Figure 6 for lift truck models below equipped with a Cummins QSB 3.3L diesel engine • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (G813 • GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (D879) See Figure 7 for lift truck models below equipped with Yanmar 2.6L diesel engine • GDP20-25LX (GDP050LX) (A974) See Figure 8 for lift truck models below equipped with a Kubota 3.8L diesel engine • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (H813, J813) 18. Remove radiator from truck. 19. If necessary, remove the coolant level sensor. 5

- 10. Radiator Replacement 700 YRM 1123 Figure 1. Cooling System for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) and GLP20-25LX (GLP050LX) (A974) 6

- 11. 700 YRM 1123 Radiator Replacement Legend for Figure 1 A. RADIATOR WITH EXTERNAL COOLER B. RADIATOR WITH INTERNAL COOLER, MODINE SHOWN C. RESERVOIR BEFORE MAY ’06 D. RESERVOIR AFTER MAY ’06 1. RADIATOR 2. CAP 3. UPPER HOSE 4. LOWER HOSE 5. CLAMP 6. SHROUD 7. CLIP 8. WASHER 9. SCREW 10. CLIP 11. UPPER RADIATOR BRACKET 12. CAPSCREW, GC/GLC040-070VX, GC/GLC055SVX [A910] AND GLC050LX (A967) 13. INSERT 14. LOWER BRACKET, GC/GLC040-070VX, GC/GLC055SVX [A910] AND GLC050LX (A967) 15. NUT-CLIP, GC/GLC040-070VX, GC/GLC055SVX [A910] AND GLC050LX (A967) 16. ISOLATOR 17. COOLANT LEVEL SENSOR 18. RESERVOIR 19. TUBE 20. OUTLET ASSEMBLY 21. HOSE 22. RESERVOIR OUTLET 23. CAP 24. BUSHING 25. SCREEN ASSEMBLY (OPTIONAL) 26. HEAT SHIELD 27. RESERVOIR BRACKET 28. HEAT SHIELD, GLP/GDP20-35VX (GP/GLP/GDP040-070VX) [B875] AND GLP20-25LX (GLP050LX) (A974) 7

- 12. Radiator Replacement 700 YRM 1123 Figure 2. Cooling System for Lift Truck Models GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818) Before 2011 8

- 13. 700 YRM 1123 Radiator Replacement Legend for Figure 2 A. RADIATOR WITH EXTERNAL COOLER B. RADIATOR WITH INTERNAL COOLER 1. RADIATOR 2. SHROUD 3. WASHER 4. SCREW 5. CLIP NUT 6. CLIP 7. UPPER HOSE 8. LOWER HOSE 9. CLAMP 10. UPPER RADIATOR BRACKET 11. INSERT 12. CAPSCREW 13. ISOLATOR 14. RESERVOIR 15. RESERVOIR BRACKET 16. OUTLET ASSEMBLY 17. OUTLET 18. CAP 19. BUSHING 20. HOSE 21. TUBE 22. STRAP 23. NUT 24. SCREEN 25. BAFFLE (RH AND LH) 26. RADIATOR CAP 27. COOLANT LEVEL SENSOR 9

- 14. Radiator Replacement 700 YRM 1123 Figure 3. Cooling System for Lift Truck Models GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) After 2011 10

- 15. 700 YRM 1123 Radiator Replacement Legend for Figure 3 A. RADIATOR WITH EXTERNAL COOLER B. RADIATOR WITH INTERNAL COOLER 1. RADIATOR 2. SHROUD 3. WASHER 4. SCREW 5. CLIP NUT 6. CLIP 7. UPPER HOSE 8. LOWER HOSE 9. CLAMP 10. UPPER RADIATOR BRACKET 11. INSERT 12. CAPSCREW 13. ISOLATOR 14. RESERVOIR 15. OUTLET ASSEMBLY 16. OUTLET 17. CAP 18. BUSHING 19. HOSE 20. TUBE 21. NUT 22. SCREEN 23. BAFFLE (RH AND LH) 24. RADIATOR CAP 25. COOLANT LEVEL SENSOR 11

- 16. Radiator Replacement 700 YRM 1123 Figure 4. Cooling System for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813) Before 2011 12

- 17. 700 YRM 1123 Radiator Replacement Legend for Figure 4 A. RADIATOR WITH INTERNAL COOLER B. RADIATOR WITH EXTERNAL COOLER 1. CAPSCREW 2. INSERT 3. UPPER RADIATOR BRACKET 4. RADIATOR CAP 5. ISOLATOR 6. CLIP NUT 7. COOLANT LEVEL SENSOR 8. RADIATOR 9. CLIP 10. RADIATOR SHROUD 11. CLAMP 12. LOWER HOSE 13. SCREW 14. WASHER 15. SCREEN 16. STRAP 17. RESERVOIR BRACKET 18. RESERVOIR 19. OUTLET ASSEMBLY 20. OUTLET 21. CAP 22. BUSHING 23. TUBE 24. UPPER HOSE 25. DRAIN PLUG 26. OIL COOLER 13

- 18. Radiator Replacement 700 YRM 1123 Figure 5. Cooling System for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813) After 2011 14

- 19. 700 YRM 1123 Radiator Replacement Legend for Figure 5 A. RADIATOR WITH INTERNAL COOLER B. RADIATOR WITH EXTERNAL COOLER 1. CAPSCREW 2. INSERT 3. UPPER RADIATOR BRACKET 4. RADIATOR CAP 5. ISOLATOR 6. CLIP NUT 7. COOLANT LEVEL SENSOR 8. RADIATOR 9. CLIP 10. RADIATOR SHROUD 11. CLAMP 12. LOWER HOSE 13. SCREW 14. WASHER 15. SCREEN 16. RESERVOIR 17. OUTLET ASSEMBLY 18. OUTLET 19. CAP 20. BUSHING 21. TUBE 22. UPPER HOSE 23. DRAIN PLUG 24. OIL COOLER 15

- 20. Radiator Replacement 700 YRM 1123 1. RADIATOR 2. RADIATOR CAP 3. HARNESS CLIP 4. UPPER RADIATOR BRACKET 5. INSERT 6. ISOLATOR 7. CAPSCREW 8. CLAMP 9. TUBE 10. UPPER HOSE 11. CLAMP 12. CHARGE AIR COOLER HOSE 13. CLAMP 14. CHARGE AIR COOLER HOSE 15. SHROUD 16. CLAMP 17. CHARGE AIR COOLER HOSE 18. SCREW 19. WASHER 20. CLIP 21. LOWER HOSE 22. RESERVOIR 23. BUSHING 24. RESERVOIR CAP 25. RESERVOIR OUTLET 26. HOSE 27. TUBE 28. COOLANT LEVEL SENSOR 29. SEAL Figure 6. Cummins 3.3L Cooling System With Charge Air Cooler for GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (G813) 16

- 21. 700 YRM 1123 Radiator Replacement 1. LOWER HOSE 2. CLAMP 3. UPPER HOSE 4. RESERVOIR 5. OUTLET ASSEMBLY 6. BUSHING 7. CAP 8. RESERVOIR OUTLET 9. HOSE 10. CAPSCREW 11. INSERT 12. RADIATOR CAP 13. ISOLATOR 14. UPPER RADIATOR BRACKET 15. RADIATOR 16. PLUG - COOLANT LEVEL SENSOR 17. HEAT SHIELD 18. CLIP NUT 19. WASHER 20. SCREW 21. DRAIN PLUG 22. SHROUD 23. TUBE Figure 7. Yanmar 2.6L Cooling System for Lift Truck Models GDP20-25LX (GDP050LX) (A974) 17

- 22. Radiator Replacement 700 YRM 1123 1. RADIATOR 2. RADIATOR CAP 3. UPPER RADIATOR BRACKET 4. ISOLATOR 5. CAPSCREW 6. INSERT 7. CLAMP 8. TUBE 9. UPPER HOSE 10. LOWER HOSE 11. TRANSMISSION COOLER RETURN LINE 12. TRANSMISSION COOLER SUPPLY LINE 13. SCREW 14. WASHER 15. SHROUD 16. RESERVOIR 17. BUSHING 18. RESERVOIR CAP 19. RESERVOIR OUTLET 20. COOLANT LEVEL SENSOR Figure 8. Kubota 3.8L Cooling System for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (H813, J813) 18

- 23. 700 YRM 1123 Radiator Replacement RADIATOR, REMOVE FOR LIFT TRUCKS MODELS GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC050LX (A967) AND GLP/GDP20-25LX (GLP/GDP050LX) (A974) EQUIPPED WITH OIL COOLER WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. 1. Turn OFF truck. 2. Remove the hood and seat combination. See section Frame 100 YRM 1120 for lift truck mod- els • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) See section Frame 100 YRM 1423 for lift truck mod- els • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) WARNING Always disconnect the cable at the negative termi- nal first. Install a tag on the battery terminals so that no one connects the cables on the terminals. 3. Disconnect the negative battery cable. 4. Disconnect the positive battery cable. WARNING DO NOT remove the radiator cap from the radiator when the engine is hot. When the radiator cap is removed, the pressure is released from the system. If the system is hot, the steam and boiling coolant can cause burns. 5. Let coolant cool to ambient temperature. Place a drain pan with a capacity greater than the capacity of the cooling system under radiator. Remove radi- ator cap. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. 6. Open the drain plug or loosen hose clamp and dis- connect the lower hose. 7. Loosen clamps and disconnect oil cooler hoses from oil cooler adapters. See Figure 9. 8. Remove oil cooler adapters and O-rings from radi- ator. Discard O-rings. See Figure 9. 9. Once coolant is drained from engine, loosen hose clamps and disconnect coolant hoses from radiator. Cap radiator hoses. 10. Loosen hose clamp and disconnect hose from reservoir and remove reservoir. See Figure 9. 11. Remove battery and battery tray. 12. If equipped, disconnect electrical connector to the coolant level sensor. NOTE: For Mazda LPG engine, the LPG converter bracket needs to be moved for clearance of radiator. 13. Remove screws and washers from the shroud and move shroud out of the way. 14. Place radiator guard shield between radiator and fan so damage to radiator does not occur during fan removal. 15. Remove fan, fan spacer, and pulley. 16. Remove radiator guard shield. 17. Remove capscrews and upper radiator bracket. See Figure 9. 18. Remove radiator from truck. 19. If necessary, remove the coolant level sensor. 19

- 24. Radiator Replacement 700 YRM 1123 1. RADIATOR 2. CAP 3. UPPER HOSE 4. LOWER HOSE 5. CLAMP 6. SHROUD 7. O-RING 8. OIL COOLER ADAPTER 9. OIL COOLER HOSE 10. UPPER RADIATOR BRACKET 11. CAPSCREW 12. INSERT 13. ISOLATOR 14. RESERVOIR 15. TUBE 16. OUTLET ASSEMBLY 17. HOSE 18. RESERVOIR OUTLET 19. CAP 20. BUSHING Figure 9. Cooling System for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC050LX (A967) and GLP20-25LX (GLP050LX) (A974) 20

- 25. 700 YRM 1123 Radiator Replacement RADIATOR, REMOVE FOR LIFT TRUCK MODELS S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. 1. Turn off truck. WARNING Always disconnect the cable at the negative termi- nal first. Install a tag on the battery terminals so that no one connects the cables on the terminals. 2. Disconnect the negative battery cable. 3. Disconnect the positive battery cable. 4. Remove radiator cover. See Figure 10. 5. Remove debris cover. CAUTION The counterweight cover is extremely heavy 185 kg (408 lb). Make sure that the eyebolts and lifting de- vice have sufficient capacity to lift the weight. 6. Remove two bolts from counterweight cover. 7. Install two eyebolts in the hole on each end of the counterweight cover. Connect a suitable lifting de- vice to the eyebolts and carefully remove the coun- terweight cover from lift truck. 8. Remove four capscrews from upper radiator bracket. Remove bracket. See Figure 23. 9. If necessary, disconnect electrical connector from the coolant level sensor. 10. Remove screws, washers, and clip nuts from the shroud and radiator and move shroud out of the way. 11. Place a radiator guard shield between radiator and fan so damage to radiator does not occur during fan removal. 12. Remove fan. See Fan Removal procedures. 13. Remove radiator guard shield. WARNING DO NOT remove the radiator cap from the radiator when the engine is hot. When the radiator cap is removed, the pressure is released from the system. If the system is hot, the steam and boiling coolant can cause burns. 14. Let coolant cool to ambient temperature. Place a drain pan with a capacity greater than the capacity of the cooling system under the radiator. Remove radiator cap. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. 15. Open drain plug, loosen clamp and disconnect the lower radiator hose from radiator to allow coolant to drain into a suitable container. Install caps on hose. See Figure 10. 16. Once coolant is drained from engine, loosen hose clamp and disconnect upper radiator hose from ra- diator. Install cap on hose. See Figure 10. 17. Lift trucks equipped with a Cummins QSB 3.3L diesel engine: Loosen clamps and disconnect the charge air cooler hoses from charge air cooler. See Figure 11. 18. Loosen clamp and disconnect remote refill hose from radiator. Install cap on hose. NOTE: Tag the transmission lines before disconnecting from oil cooler. 19. Disconnect transmission lines from oil cooler. In- stall caps on transmission lines. Drain transmission oil from oil cooler into a suitable container. Install caps on the oil cooler ports. NOTE: Removing the radiator from lift truck requires two people. 20. Remove radiator from lift truck frame. 21. If necessary, remove the coolant level sensor from radiator. See Figure 23. 21

- 26. Radiator Replacement 700 YRM 1123 Figure 10. Radiator Removal for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) Legend for Figure 10 1. DEBRIS COVER 2. COUNTERWEIGHT COVER 3. RADIATOR COVER 4. UPPER BRACKET 5. CAPSCREWS 6. REMOTE FILL HOSE 7. HOSE CLAMPS 8. OIL COOLER 9. TRANSMISSION OIL COOLER LINES 10. FITTINGS 11. UPPER HOSE 12. LOWER HOSE 13. REMOTE FILL 14. RADIATOR CAP 22

- 27. 700 YRM 1123 Radiator Replacement 1. RADIATOR 2. RADIATOR CAP 3. HARNESS CLIP 4. UPPER RADIATOR BRACKET 5. INSERT 6. ISOLATOR 7. CAPSCREW 8. CLAMP 9. TUBE 10. UPPER HOSE 11. CLAMP 12. CHARGE AIR COOLER HOSE 13. CLAMP 14. CHARGE AIR COOLER HOSE 15. SHROUD 16. CLAMP 17. CHARGE AIR COOLER HOSE 18. SCREW 19. WASHER 20. CLIP 21. LOWER HOSE 22. RESERVOIR 23. BUSHING 24. RESERVOIR CAP 25. RESERVOIR OUTLET 26. HOSE 27. TUBE 28. COOLANT LEVEL SENSOR 29. SEAL Figure 11. Cummins 3.3L Cooling System With Charge Air Cooler for GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (D879) 23

- 28. Radiator Replacement 700 YRM 1123 RADIATOR, REMOVE FOR LIFT TRUCK MODELS GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) AND GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. 1. Turn off truck. WARNING Always disconnect the cable at the negative termi- nal first. Install a tag on the battery terminals so that no one connects the cables on the terminals. 2. Disconnect the negative battery cable. 3. Disconnect the positive battery cable. NOTE: Perform Step 4 for lift truck models GLP/ GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878). 4. Open hood and loosen clamp and disconnect inlet hose that attaches to the hood support. See Fig- ure 25. NOTE: Perform Step 5 for lift truck model GDP80VX, GDP80VX9, GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909). 5. Open hood, loosen clamp, and disconnect dirty air hose attached to hood support. See Figure 26 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) See Figure 27 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP/GLP170VX, GLP/GLP175VX36, GLP/GLP190VX) (A909, B909) See Figure 28 for lift truck models equipped with Kubota 3.8L Diesel engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (B909) 6. Lift trucks equipped with GM 4.3L (Gas/LPG) en- gine, loosen clamp and disconnect inlet hose from air filter and remove inlet hose. See Figure 25. NOTE: Perform Step 7 for lift truck models GLP/ GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878). 7. Lift trucks equipped with the Kubota 3.8L, Cummins 4.5L, or QSB 3.3L diesel engine loosen clamp and disconnect inlet hose from silencer. Remove si- lencer. See Figure 25. NOTE: Before lifting the hood assembly from the lift truck frame, make sure to use a lifting device and lift- ing straps as shown in Figure 12. The hood assembly weighs approximately 45.6 kg (101 lb). 8. Remove hood assembly. For hood assembly re- moval procedures, see Frame 100 YRM 1321 for lift truck models • GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36,GLP/GDP190VX) (A909) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C879, D879) Frame 100 YRM 1581 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (B909) 9. Disconnect and cap auxiliary coolant reservoir hose. See Figure 25. 10. Remove capscrews from the auxiliary coolant reservoir bracket and upper bracket. Remove auxiliary coolant reservoir assembly. 11. Remove the four capscrews from the upper radiator bracket. Remove bracket. 12. If necessary, disconnect electrical connector from the coolant level sensor. 13. Remove screws, washers and clip nuts from the shroud and move shroud out of the way. 24

- 29. 700 YRM 1123 Radiator Replacement 1. PRE-CLEANER 2. STRAP CLAMP Figure 12. Hood Assembly Removal 14. Place a radiator guard shield between radiator and fan so damage to radiator does not occur during fan removal. NOTE: Perform Step 15 for lift truck models GLP/ GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878). 15. Remove capscrews, washers, fan, fan spacer, and shroud. See Figure 25. NOTE: Perform Step 16 for lift truck model GLP GDP80VX, GLPGDP80VX9, GLPGDP90VX (GLP/ GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909). 16. Remove capscrews, washer, fan, fan spacers, and fan shroud. See Figure 13 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 14 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909 B909) See Figure 15 for lift truck models equipped with Kubota 3.8L Diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (B909) 17. Remove radiator guard shield. WARNING DO NOT remove the radiator cap from the radiator when the engine is hot. When the radiator cap is removed, the pressure is released from the system. If the system is hot, the steam and boiling coolant can cause burns. 18. Let coolant cool to ambient temperature. Place a drain pan with a capacity equal to or greater than the capacity of the cooling system under the radia- tor. Remove radiator cap. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. 19. Open drain plug or loosen clamp and disconnect lower radiator hose to allow coolant to drain. See Figure 25 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) See Figure 13 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 14 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) See Figure 15 for lift truck models equipped with Kubota 3.8L Diesel engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (B909) 20. Lift trucks equipped with a Cummins QSB 3.3L or Kubota 3.8L diesel engine, loosen clamps and dis- connect the charge air cooler hoses from radiator. See Figure 13 or Figure 15. 25

- 30. Radiator Replacement 700 YRM 1123 1. RADIATOR 2. RADIATOR CAP 3. HARNESS CLIP 4. UPPER RADIATOR BRACKET 5. INSERT 6. ISOLATOR 7. CAPSCREW 8. CLAMP 9. TUBE 10. UPPER HOSE 11. CLAMP 12. CHARGE AIR COOLER HOSE 13. CLAMP 14. CHARGE AIR COOLER HOSE 15. SHROUD 16. CLAMP 17. CHARGE AIR COOLER HOSE 18. SCREW 19. WASHER 20. CLIP 21. LOWER HOSE 22. RESERVOIR 23. BUSHING 24. RESERVOIR CAP 25. RESERVOIR OUTLET 26. HOSE 27. TUBE 28. COOLANT LEVEL SENSOR 29. SEAL Figure 13. Cummins 3.3L Cooling System With Charge Air Cooler for GDP60VX, GDP70VX (GDP135VX, GDP155VX) (D878), GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) 26

- 31. 700 YRM 1123 Radiator Replacement 21. Once coolant is drained from engine, loosen hose clamps and disconnect radiator hoses from radia- tor. Cap hoses. NOTE: Tag the transmission lines before disconnecting from oil cooler. 22. Disconnect and cap transmission lines from oil cooler and allow transmission oil to drain from oil cooler into a suitable container, then cap the oil cooler ports. 23. For lift trucks equipped with GM 5.7L LPG engine, remove capscrews from baffles and remove baffles from radiator assembly. Remove capscrews secur- ing cooling baffle to radiator assembly. See Fig- ure 14. 1. BAFFLE 2. ISOLATOR 3. UPPER BRACKET 4. CAP 5. RESERVOIR OUTLET 6. BUSHING 7. HOSE 8. RESERVOIR 9. RADIATOR 10. CAPSCREW 11. SHROUD 12. CLAMP 13. UPPER HOSE 14. LOWER HOSE 15. SEAL 16. COOLING BAFFLE 17. DRAIN HOSE 18. PLASTIC TUBE Figure 14. GM 5.7L Cooling System, Lift Truck Models GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) 27

- 32. Radiator Replacement 700 YRM 1123 Figure 15. Kubota 3.8L Cooling System, Lift Truck Model GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (B909) 28

- 33. 700 YRM 1123 Radiator Replacement Legend for Figure 15 1. RADIATOR 2. RADIATOR CAP 3. UPPER RADIATOR BRACKET 4. INSERT 5. ISOLATOR 6. CAPSCREW 7. CLAMP 8. TUBE 9. UPPER HOSE 10. CHARGE AIR COOLER HOSE 11. CHARGE AIR COOLER HOSE 12. CHARGE AIR COOLER HOSE 13. LOWER HOSE 14. SHROUD 15. RESERVOIR 16. BUSHING 17. RESERVOIR CAP 18. RESERVOIR OUTLET 19. HOSE 20. COOLANT LEVEL SENSOR 21. SEAL NOTE: Removing the radiator from lift truck requires two people. 24. Remove radiator from lift truck frame. 25. If necessary, remove the coolant level sensor from radiator. RADIATOR, INSTALL FOR LIFT TRUCK MODELS GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875); GLP/GDP20-25LX (GLP/GDP050LX) (A974); GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) AND GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) 1. If removed, install the coolant level sensor. 2. Install radiator into truck. 3. Install upper radiator bracket, using capscrews taken out during removal. 4. Place a radiator guard shield between radiator and fan, so damage to radiator does not occur during fan installation 5. Place shroud in lift truck. DO NOT install on radia- tor. NOTE: Pull radiator shroud away from radiator while installing fan, fan spacer, and pulley. 6. Install fan, fan spacer, and pulley. 7. Remove radiator guard shield. 8. Install the radiator shroud on radiator using screws and washers taken out during removal.. 9. If equipped, connect the electrical connector to the coolant level sensor. NOTE: For Mazda LPG engine, the LPG converter bracket and screws must be installed to hold the con- verter. 10. Uncap radiator and reservoir ports and install the reservoir. 11. Connect the reservoir hose from reservoir to the radiator. Tighten hose clamp. 12. Lift trucks equipped with Cummins QSB 3.3L en- gine, uncap the charge air cooler hoses and con- nect the hoses to charge air cooler. See Figure 6. 13. Lift trucks equipped with Kubota 3.8L diesel en- gine: Uncap transmission cooler hoses and con- nect hoses to transmission cooler. See Figure 8. 14. Uncap the upper hose and connect the hose to ra- diator. Tighten hose clamp. 15. Close the drain plug or install lower hose. Tighten hose clamp. 29

- 34. Radiator Replacement 700 YRM 1123 WARNING DO NOT use an alcohol or methanol base an- tifreeze. They are flammable and could cause personal injury or damage to the lift truck. CAUTION Additives may damage the cooling system. Before using additives, contact your local Yale dealer. 16. Fill cooling system with ethylene glycol boron-free antifreeze. Purchase a pre-diluted 50/50 solution; or mix 50% concentrate with 50% distilled or deion- ized water. The 50/50 mixture will protect cooling system to 37°C ( 35°F). 17. Use the same coolant mixture and fill the reservoir between the ADD and FULL marks. See Figure 16 or Figure 17, for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875 • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) See Figure 18, for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813) See Figure 19 for lift truck models • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (H813, J813) 1. RESERVOIR 2. ADD MARK 3. FULL MARK Figure 16. Reservoir for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) and GLP/GDP20-25LX (GLP/GDP050LX) (A974) Before May ’06 30

- 35. 700 YRM 1123 Radiator Replacement 1. RESERVOIR 2. ADD MARK 3. FULL MARK Figure 17. Reservoir for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910); GLC050LX (A967); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) and GLP/GDP20-25LX (GLP/GDP050LX) (A974) After May ’06 1. AUXILIARY COOLANT RESERVOIR 2. FULL "HOT" MARK 3. FULL "COLD" MARK 4. ADD "COLD" MARK Figure 18. Reservoir for Lift Truck Models GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50- 55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813) 31

- 36. Radiator Replacement 700 YRM 1123 1. AUXILIARY COOLANT RESERVOIR 2. FULL "HOT" MARK 3. FULL "COLD" MARK 4. ADD "COLD" MARK Figure 19. Reservoir for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/ GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (H813, J813) 18. Install battery and battery tray. 19. Connect the positive battery cable. 20. Connect negative battery cable. 21. Install the hood and seat combination. See section Frame 100 YRM 1120 for lift truck mod- els • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) See section Frame 100 YRM 1243 for lift truck mod- els • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) See section Frame 100 YRM 1423 for lift truck mod- els • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. Contact with these parts can cause serious injury. WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. 22. Start and run engine until thermostat opens. (The upper hose will be warm.) 23. On lift trucks equipped with a GM 2.4L engine, bleed air from the cooling system by opening the bleed screw located on the left side behind the alternator. When the air has been bled from the system close the bleed screw. See Figure 20. CAUTION Additives may damage the cooling system. Before using additives, contact your local Yale dealer. 24. Check coolant level at the reservoir. Add coolant as necessary to keep level between the ADD and FULL marks on the reservoir. 32

- 37. 700 YRM 1123 Radiator Replacement 1. MANIFOLD 2. COOLANT HOSES 3. BLEED SCREW 4. RADIATOR HOSE Figure 20. Bleed Screw, GM 2.4L Engine RADIATOR, INSTALL FOR LIFT TRUCK MODELS GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC050LX (A967) AND GLP/GDP20-25LX (GLP/GDP050LX) (A974) EQUIPPED WITH OIL COOLER 1. If removed, install the coolant level sensor. 2. Install radiator into truck. 3. Install upper radiator bracket, using capscrews taken out during removal. 4. Place a radiator guard shield between radiator and fan, so damage to radiator does not occur during fan installation 5. Place shroud in lift truck. DO NOT install on radia- tor. NOTE: Pull radiator shroud away from radiator while installing fan, fan spacer, and pulley. 6. Install fan, fan spacer, and pulley. 7. Remove radiator guard shield. 8. Install the radiator shroud on radiator using screws and washers taken out during removal.. 9. If equipped, connect the electrical connector to the coolant level sensor. NOTE: For Mazda LPG engine, the LPG converter bracket and screws must be installed to hold the con- verter. 10. Uncap radiator and reservoir ports and install the reservoir. 11. Connect the reservoir hose from reservoir to the radiator. Tighten hose clamp. See Figure 9. 12. Install new O-rings on oil cooler connectors. See Figure 9. 13. Install oil cooler adapters to radiator. Torque adapters to 14.7 to 17.6 N•m (130 to 156 lbf in). See Figure 9. 14. Uncap oil cooler hoses and connect hoses to oil cooler adapters. See Figure 9. 15. Uncap the upper hose and connect the hose to ra- diator. Tighten hose clamp. See Figure 9. 16. Close the drain plug or install lower hose. Tighten hose clamp. WARNING DO NOT use an alcohol or methanol base an- tifreeze. They are flammable and could cause personal injury or damage to the lift truck. CAUTION Additives may damage the cooling system. Before using additives, contact your local Yale dealer. 17. Fill cooling system with ethylene glycol boron-free antifreeze. Purchase a pre-diluted 50/50 solution; or mix 50% concentrate with 50% distilled or deion- ized water. The 50/50 mixture will protect cooling system to 37°C ( 35°F). 18. Use the same coolant mixture and fill the reservoir between the ADD and FULL marks. See Figure 21. 33

- 38. Radiator Replacement 700 YRM 1123 1. RESERVOIR 2. ADD MARK 3. FULL MARK Figure 21. Reservoir for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810); GLC050LX (A967) and GLP/GDP20-25LX (GLP/GDP050LX) (A974) 19. Install battery and battery tray. 20. Connect the positive battery cable. 21. Connect negative battery cable. 22. Install the hood and seat combination. See section Frame 100 YRM 1120 for lift truck mod- els • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) See section Frame 100 YRM 1423 for lift truck mod- els • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. Contact with these parts can cause serious injury. WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. 23. Start and run engine until thermostat opens. (The upper hose will be warm.) CAUTION Additives may damage the cooling system. Before using additives, contact your local Yale dealer. 24. Check coolant level at the reservoir. Add coolant as necessary to keep level between the ADD and FULL marks on the reservoir. RADIATOR, INSTALL FOR LIFT TRUCK MODELS S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) 1. If necessary, install coolant level sensor. NOTE: Installing the radiator into lift truck frame re- quires two people. 2. Install radiator into lift truck frame. 3. Remove caps from the oil cooler and transmission lines and connect lines into oil cooler. See Fig- ure 10. 4. Uncap and connect remote refill hose onto radiator and tighten hose clamp. See Figure 10. 5. Close drain plug and uncap the upper and lower radiator hoses and connect hoses onto radiator and tighten hose clamps. See Figure 10. 6. Uncap the charge air cooler hoses and connect the hoses to charge air cooler. See Figure 11. 7. Install fan. See Fan Installation procedures. 8. Align shroud to radiator and install two capscrews, washers and clip nuts. See Figure 23. 34

- 39. 700 YRM 1123 Radiator Replacement 9. If necessary, connect electrical connector onto the coolant level sensor. 10. Install upper radiator bracket and four capscrews. CAUTION The counterweight cover is extremely heavy 185 kg (408 lb). Make sure that the eyebolts and lifting de- vice have sufficient capacity to lift the weight. 11. If removed, install two eyebolts in the hole on each end of the counterweight cover. Connect a suitable lifting device to the eyebolts and carefully install the counterweight cover into the lift truck frame. See Figure 10. 12. Install two bolts to counterweights cover. Tighten to 38 N•m (28 lbf ft). 13. Install debris cover. 14. Install radiator cover. 15. Connect positive battery cable. 16. Connect negative battery cable. WARNING DO NOT use an alcohol or methanol base an- tifreeze. They are flammable and could cause personal injury or damage to the lift truck. CAUTION Additives may damage the cooling system. Before using additives, contact you local Yale dealer. 17. Fill cooling system with ethylene glycol boron-free antifreeze. Purchase a pre-diluted 50/50 solution; or mix 50% concentrate with 50% distilled or deion- ized water. The 50/50 mixture will protect cooling system to 37°C ( 35°F). 18. Install radiator cap. 19. Use the same coolant mixture and fill the reservoir between the ADD and FULL marks. See Figure 22. WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. contact with these parts can cause serious injury. WARNING The radiator or other parts of the cooling system may be hot or under pressure and cause serious injury. 20. Start and run the engine until thermostat opens (The upper radiator hose will be warm). CAUTION Additives may damage the cooling system. Before using additives, contact you local Yale dealer. 21. Check coolant level at the auxiliary coolant reser- voir. Add coolant as necessary to keep level be- tween the ADD and FULL marks on the reservoir. 22. Shut down the engine for one minute or longer prior to checking the transmission oil level. If the trans- mission oil is low, add transmission oil to the trans- mission at the dipstick tube to the correct level in- dicated on the dipstick. Oil is specified in Periodic Maintenance section for your lift truck. 1. AUXILIARY COOLANT RESERVOIR 2. FULL "HOT" MARK 3. FULL "COLD" MARK 4. ADD "COLD" MARK Figure 22. Reservoir for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) 35

- 40. Radiator Replacement 700 YRM 1123 Figure 23. Cooling System for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) 36

- 41. 700 YRM 1123 Radiator Replacement Legend for Figure 23 A. LOWER HOSE (CUMMINS 4.5L/KUBOTA 3.8L DIESEL) B. LOWER HOSE (GAS AND LPG) C. UPPER HOSE (GAS AND LPG) D. UPPER HOSE (CUMMINS 4.5L/KUBOTA 3.8L DIESEL) 1. RADIATOR (WITH EXTERNAL OIL COOLER) 2. SHROUD 3. WASHER 4. SCREW 5. CLIP NUT 6. CLIP SPRING 7. CLAMP 8. UPPER RADIATOR BRACKET 9. CAPSCREW 10. INSERT 11. ISOLATOR 12. RESERVOIR 13. BRACKET (COOLANT FILL) 14. OUTLET ASSEMBLY 15. OUTLET 16. CAP 17. BUSHING 18. HOSE 19. HOSE 20. REMOTE FILL HOSE 21. REMOTE FILL 22. RADIATOR CAP 23. SCREEN 24. COOLANT LEVEL SENSOR 25. DRAIN PLUG RADIATOR, INSTALL FOR LIFT TRUCK MODELS GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) AND GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 1. If necessary, install coolant level sensor. NOTE: Installing the radiator into lift truck frame re- quires two people. 2. Install radiator into lift truck frame. 3. For lift trucks equipped with GM 5.7L LPG engine, use capscrews and install baffles to radiator assem- bly. See Figure 14. Use capscrews and attach ra- diator assembly to cooling baffle. 4. Install upper radiator bracket and four capscrews. See Figure 25 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) See Figure 13 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 14 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) See Figure 15 for lift truck models equipped with Kubota 3.8L Diesel engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (B909) 5. Install coolant reservoir bracket and coolant reser- voir assembly onto upper bracket and tighten cap- screws. See Figure 25 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) See Figure 13 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 14 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) See Figure 15 for lift truck models equipped with Kubota 3.8L Diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (B909) 6. Uncap and connect auxiliary coolant reservoir hose and tighten clamp. 7. Remove caps from the oil cooler and transmission lines and connect lines into oil cooler. 8. Close drain plug and uncap the lower radiator hose and connect hose onto radiator and tighten clamp. 37

- 42. Radiator Replacement 700 YRM 1123 9. Uncap and connect upper radiator hose and tighten clamp. 10. Lift trucks equipped with Cummins QSB 3.3L or Kubota 3.8L diesel engine, uncap the charge air cooler hoses and connect the hoses to the charge air cooler. See Figure 13 or Figure 15. 11. Install fan. See Fan Installation procedures. 12. Align shroud to radiator and install capscrews, washers and clip nuts. See Figure 25 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) See Figure 13 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 14 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) See Figure 15 for lift truck models equipped with Kubota 3.8L Diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (B909) 13. If necessary, connect electrical connector onto the coolant level sensor. 14. Lift truck equipped GM 4.3L (Gas/LPG) engine, in- stall air intake hose to air filter and tighten clamp. 15. Lift trucks equipped with Cummins 4.5L or QSB 3.3L diesel engine, install silencer and connect hose from air filter side and tighten clamp. See Figure 25. 16. Lift trucks equipped with Cummins QSB 3.3L, Kub- ota 3.8L diesel engine or GM 5.7L LPG engine, con- nect dirty air hose to hood support and install and tighten clamp. See Figure 26 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 27 for lift truck models below equipped with GM 5.7L LPG engine • GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) See Figure 28 for lift truck models equipped with Kubota 3.8L Diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (B909) 17. Install hood assembly. For hood install procedures, see section Frame 100 YRM 1321 for lift truck models • GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36,GLP/GDP190VX) (A909) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C879, D879) Frame 100 YRM 1581 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (B909) 18. Lift truck equipped GM 4.3L (Gas/LPG) engine, open hood assembly and connect intake hose to hood support and tighten clamp. See Figure 25. 19. Lift trucks equipped with Kubota 3.8L, Cummins 4.5L, or QSB 3.3L diesel engine, open hood assem- bly and connect hose to hood support and tighten clamp. See Figure 25 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) See Figure 26 for lift truck models below equipped with Cummins QSB 3.3L diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 28 for lift truck models equipped with Kubota 3.8L Diesel engine • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (B909) 20. Connect positive battery cable. 21. Connect negative battery cable. 38

- 43. 700 YRM 1123 Radiator Replacement WARNING DO NOT use an alcohol or methanol base an- tifreeze. They are flammable and could cause personal injury or damage to the lift truck. CAUTION Additives may damage the cooling system. Before using additives, contact you local Yale dealer. 22. Fill cooling system with ethylene glycol boron-free antifreeze. Purchase a pre-diluted 50/50 solution; or mix 50% concentrate with 50% distilled or deion- ized water. The 50/50 mixture will protect cooling system to 37°C ( 35°F). 23. Install radiator cap. 24. Use the same coolant mixture and fill the auxil- iary coolant reservoir between the ADD and FULL marks. See Figure 24. WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. contact with these parts can cause serious injury. WARNING The radiator or other parts of the cooling system may be hot or under pressure and cause serious injury. 25. Start and run the engine until thermostat opens (The upper radiator hose will be warm). CAUTION Additives may damage the cooling system. Before using additives, contact you local Yale dealer. 26. Check coolant level at the auxiliary coolant reser- voir. Add coolant as necessary to keep level be- tween the ADD and FULL marks on the reservoir. 27. Shut down the engine for one minute or longer prior to checking the transmission oil level. If the trans- mission oil is low, add transmission oil at the dipstick tube at the correct level indicated on the dipstick. Oil is specified in Periodic Maintenance section for your lift truck. 1. AUXILIARY COOLANT RESERVOIR 2. FULL "HOT" MARK 3. FULL "COLD" MARK 4. ADD "COLD" MARK Figure 24. Reservoir for Lift Truck Models GLP/ GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 39

- 44. Radiator Replacement 700 YRM 1123 Figure 25. Cooling System for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) (Sheet 1 of 3) 40

- 45. 700 YRM 1123 Radiator Replacement Figure 25. Cooling System for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) (Sheet 2 of 3) 41

- 46. Radiator Replacement 700 YRM 1123 Figure 25. Cooling System for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) (Sheet 3 of 3) 42

- 47. 700 YRM 1123 Radiator Replacement Legend for Figure 25 A. GM 4.3L (GAS/LPG) B. CUMMINS 4.5L (DIESEL) C. KUBOTA (DIESEL) 1. AIR INTAKE (WITHOUT PRE-CLEANER) 2. PRE-CLEANER 3. HOOD ASSEMBLY 4. CLAMP 5. INLET HOSE 6. SILENCER (DIESEL) 7. AIR FILTER 8. UPPER RADIATOR BRACKET 9. ISOLATOR 10. INSERT 11. CAPSCREW 12. RADIATOR (WITH EXTERNAL OIL COOLER) 13. UPPER HOSE 14. LOWER HOSE 15. CLIP NUT 16. WASHER 17. SCREW 18. SHROUD 19. FAN 20. FAN SPACER 21. TRANSMISSION LINES 22. AUXILIARY COOLANT RESERVOIR AND BRACKET ASSEMBLY 23. OUTLET 24. CAP 25. BUSHING 26. HOSE 27. AUXILIARY COOLANT RESERVOIR HOSE 28. DRAIN PLUG 29. RADIATOR CAP 30. HOOD SUPPORT 43

- 48. Radiator Replacement 700 YRM 1123 1. PRE-CLEANER 2. CLAMP 3. HOOD SUPPORT 4. HOOD ASSEMBLY 5. DIRTY AIR HOSE 6. CLEAN AIR HOSE 7. AIR FILTER 8. AIR CLEANER BRACKET 9. CAPSCREW 10. NUT 11. AUXILIARY COOLANT RESERVOIR HOSE 12. RESERVOIR OUTLET 13. CAP 14. BUSHING 15. COOLANT RECOVERY RESERVOIR 16. TUBE 17. COOLANT LEVEL SENSOR 18. UPPER BRACKET 19. RADIATOR ISOLATOR 20. RADIATOR 21. CAC HOSE 22. CAC TUBE 23. INSULATED CLAMP 24. LOWER RADIATOR HOSE 25. UPPER RADIATOR HOSE 26. SHROUD AND BAFFLE 27. WASHER 28. FAN 29. SPACER 30. AUXILIARY COOLANT RESERVOIR ASSEMBLY 31. CLIP NUT Figure 26. Cooling System Cummins QSB 3.3L Diesel Engine for Lift Truck Model GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) 44

- 49. 700 YRM 1123 Radiator Replacement 1. PRE-CLEANER 2. CLAMP 3. HOOD SUPPORT 4. HOOD 5. DIRTY AIR HOSE 6. CLEAN AIR HOSE 7. AIR FILTER 8. AIR CLEANER BRACKET 9. CAPSCREW 10. NUT 11. RADIATOR ISOLATOR 12. UPPER BRACKET 13. RADIATOR 14. BAFFLE 15. COOLANT RECOVERY RESERVOIR 16. LOWER RADIATOR HOSE 17. UPPER RADIATOR HOSE 18. SEAL 19. BAFFLE 20. FAN SHROUD 21. FAN 22. SPACER 23. FAN MOUNTING SCREWS Figure 27. Cooling System GM 5.7L LPG Engine for Lift Truck Model GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909) 45

- 50. Radiator Replacement 700 YRM 1123 Figure 28. Cooling System Kubota 3.8L Diesel Engine for Lift Truck Model GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (B909) 46

- 51. 700 YRM 1123 Fan Assembly Replacement Legend for Figure 28 1. PRE-CLEANER 2. CLAMP 3. HOOD SUPPORT 4. HOOD ASSEMBLY 5. DIRTY AIR HOSE 6. CLEAN AIR HOSE 7. AIR FILTER 8. AIR CLEANER BRACKET 9. CAPSCREW 10. NUT 11. AUXILIARY COOLANT RESERVOIR HOSE 12. RESERVOIR OUTLET 13. CAP 14. BUSHING 15. COOLANT RECOVERY RESERVOIR 16. TUBE 17. COOLANT LEVEL SENSOR 18. UPPER BRACKET 19. RADIATOR ISOLATOR 20. RADIATOR 21. CAC HOSE 22. CAC TUBE 23. AIR FLOW SENSOR 24. LOWER RADIATOR HOSE 25. UPPER RADIATOR HOSE 26. SHROUD AND BAFFLE 27. WASHER 28. FAN 29. SPACER Fan Assembly Replacement FAN REMOVAL WARNING During engine operation, be careful not to touch the fan, pulleys, or drive belts. Contact with these parts can cause serious injury. WARNING The radiator or other parts of the cooling system may be hot or under pressure and can cause seri- ous injury. Wait 30 minutes for the radiator to cool. Do a touch test by touching the radiator with your hand. If the radiator is still hot to the touch, wait an- other 30 minutes before attempting to check or fix any part of the cooling system. WARNING The radiator fins on the radiator are very sharp and can cause serious injury. Wear gloves while remov- ing fan assembly. NOTE: The fan that is used is a pusher-type fan. Do not replace with a puller-type fan. 1. Turn OFF lift truck. 2. If equipped, turn the LPG tank valve to the OFF position. 3. If equipped, release the LPG tank bracket and swing tank away from the lift truck. NOTE: Perform Step 4 through Step 6 for lift truck mod- els • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/ GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) • S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) 4. Release the steering tilt latch and move the steering wheel forward. 5. Release the seat latch and move the seat forward. 6. Release hood latch and raise hood to open posi- tion. 47

- 52. Fan Assembly Replacement 700 YRM 1123 NOTE: Perform Step 7 for lift truck models • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/ GDP190VX) (A909, B909) 7. Release hood cover latch on hood cover and swing hood cover up. WARNING To prevent a short circuit during fan belt removal, disconnect the battery negative cable at the battery negative terminal. Install a lock or tag on the con- nector to prevent connection. A tool could cause a short circuit, the high current flow from the battery can cause an injury or parts damage. 8. Disconnect the negative battery cable from the neg- ative battery terminal. 9. Remove screws and washers from the radiator shroud. Lean radiator shroud toward the fan. See Figure 29 for lift truck models below equipped with GM 2.4L, Yanmar 2.6L, Yanmar 3.0L or Yanmar 3.3L engine • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) • GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) See Figure 30 for lift truck models below equipped with Yanmar 2.6L engine. • GDP20-25LX (GDP050LX) (A974) See Figure 31 for lift truck models below equipped with Mazda FE and F2 engines • GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910) • GLC050LX (A967) • GLP20-25LX (GLP050LX) (A974) • GLP20-35VX (GP/GLP040-070VX) (B875) • GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) • GLP16VX, GLP18VX, GLP20SVX (GP/ GLP030VX, GP/GLP035VX, GP/GLP040SVX) (C810) See Figure 32 for lift truck models below equipped with GM 4.3L engine • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) See Figure 33 for lift truck models below equipped with Cummins 4.5L engine • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813) See Figure 34 for lift truck models below equipped with GM 4.3L, Cummins 4.5L, or Kubota 3.8L en- gines • S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024, F024, G024)GLC/GDC60VX, GLC/GDC60VX, (GC/GLC/GDC135VX, GC/GLC/GDC135VX) (C879, D879, E879, F879) See Figure 35 for lift truck models below equipped with GM 4.3L, Cummins 4.5L, or Kubota engines • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, E878) See Figure 36 for lift truck models below equipped with Cummins QSB 3.3L diesel engines • GDC60VX, GDC70VX (GDC135VX, GDC155VX) (D879) • GDP60VX, GDP70VX (GDP135VX, GDP155VX) (D878) • GDP40VX5/VX6; GDP45SVX5, GDP45VX6, GDP50-55VX (GDP080, 090, 100, 110, 120VX) (G813) See Figure 37 for lift truck models below equipped with Cummins QSB 3.3L diesel engines • GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909, B909) See Figure 38 for lift truck models below equipped with GM 5.7L LPG engine • GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 48