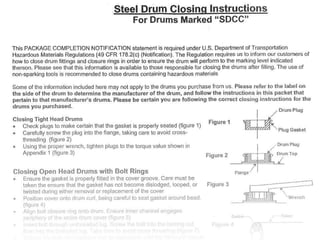

The document outlines requirements for notifying recipients of packaging transfers about compliance with regulations, including information on closures and components needed to pass performance tests. It also requires documenting procedures for assembly, closure instructions, and pressure differential guidance. Test reports must be prepared after qualification and retention tests, maintained where packaging is produced and tested for two years, and made available to users or regulators upon request. Reports must include facility information, packaging details, test descriptions and results.