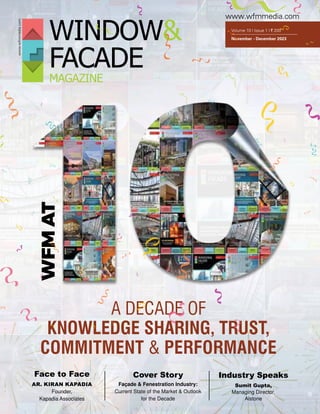

The document is a November-December 2023 issue of Window & Façade Magazine, focusing on the current state and future outlook of the façade and fenestration industry. It features insights from industry leaders, discussions on sustainable design, energy efficiency, and the importance of innovative façade solutions in modern architecture. The issue marks a decade of the magazine's existence, celebrating its role in knowledge sharing and growth within the industry.