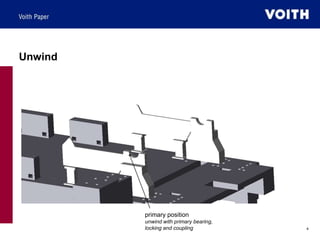

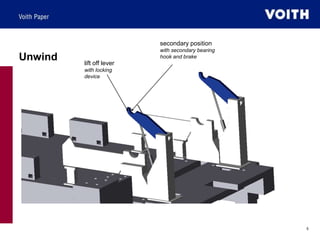

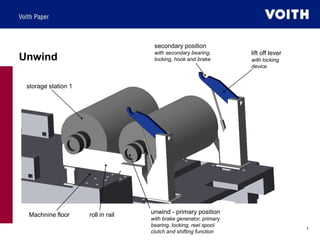

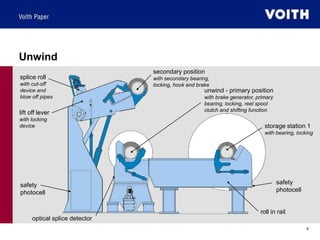

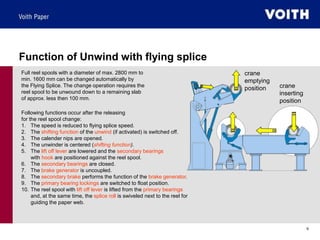

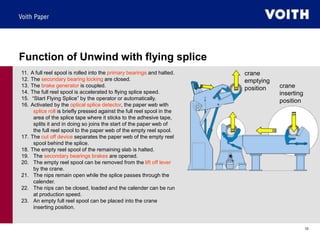

This document provides instructions for operating the unwind component of a Janus MK2 machine. It describes the various positions and functions of the unwind, including primary and secondary positions, storage stations, and the lift off lever. It also provides a detailed explanation of the flying splice function, which allows for automatic changing of full reel spools by joining a new spool to the existing web.