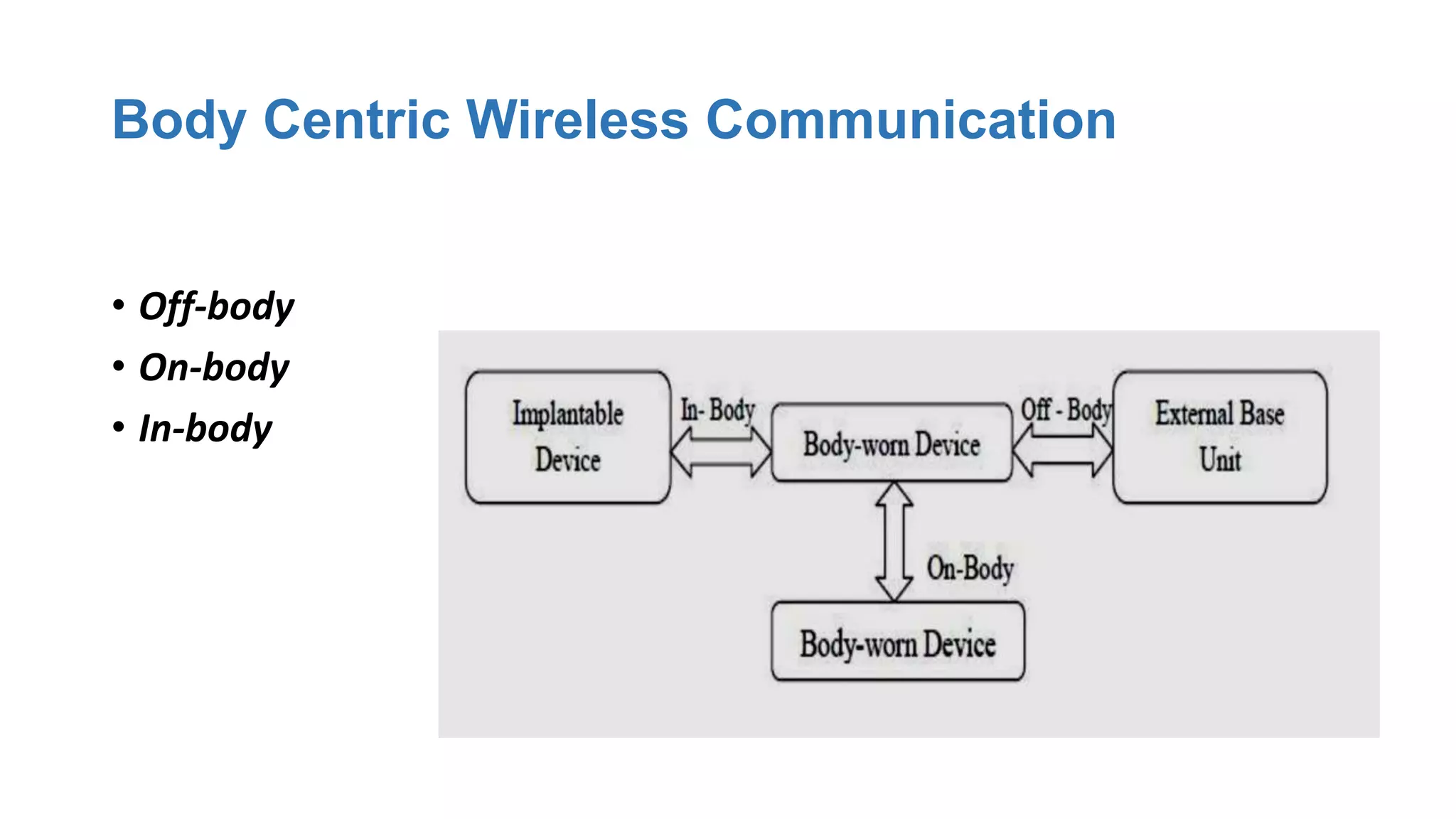

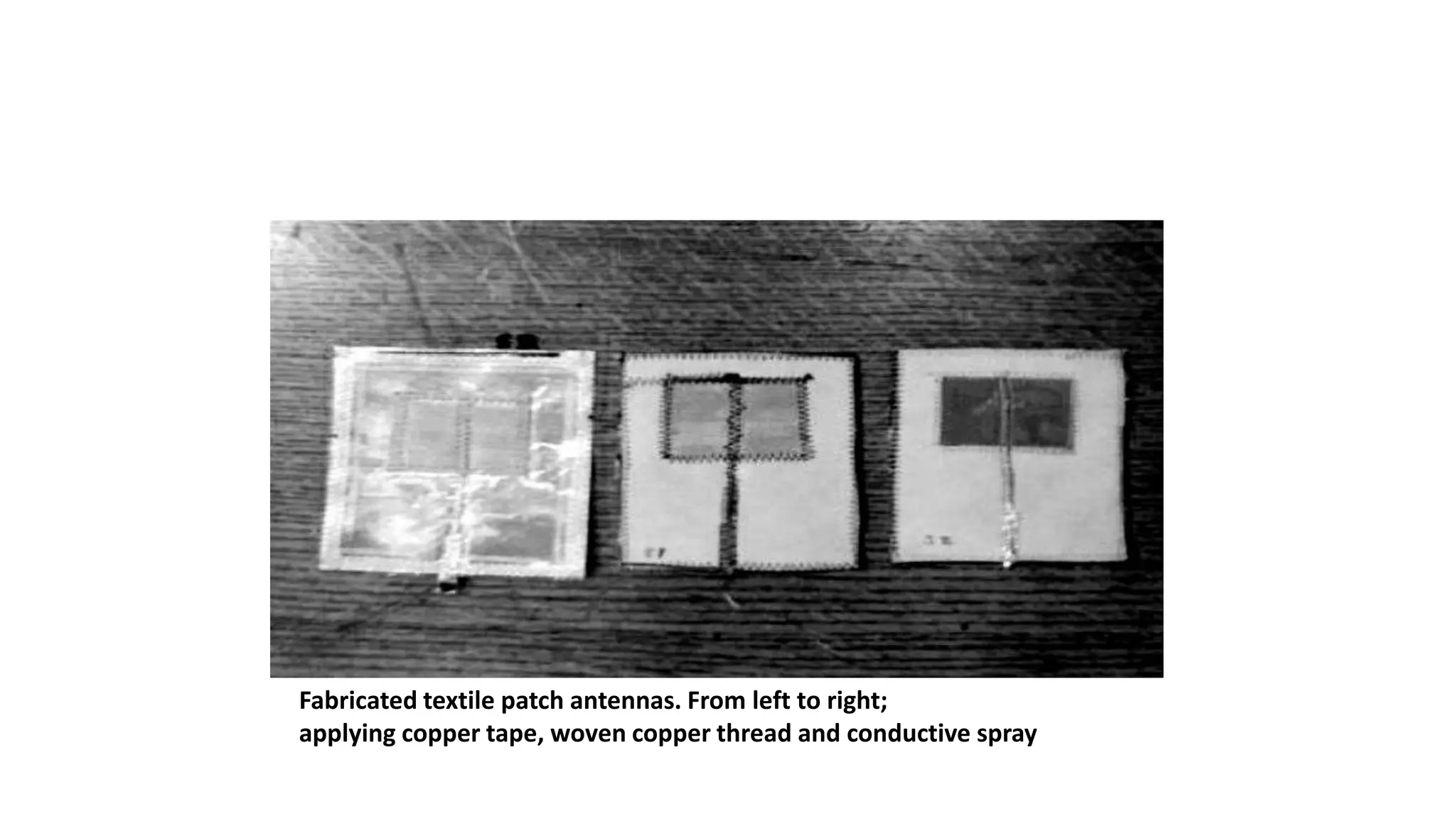

The document discusses the design, challenges, and applications of wearable textile antennas for body-centric wireless communication systems, highlighting their significance in medical, military, and fitness contexts. Key considerations include antenna performance influenced by the human body, material properties, and various fabrication methods for textile antennas. It also emphasizes advancements in technology such as smart fabrics capable of conducting energy and providing seamless integration in everyday applications.

![References

• [1] Hall, P. S., and Hao, Y., “Antennas and Propagation for Body Centric Communications”,

European Conference on Antennas and Propagation (EuCAP), November 2006.

• [2] T. Rashid, S. Noghanian, R. Fazel-Rezai and P. de Leon, “Wearable antenna design for

spacesuit,” IEEE International Symposium on Antennas and Propagation & USNC/URSI

National Radio Science Meeting, pp. 1216-1217, 2015.

• [3] J.G. Santas, A. Alomainy, H. Yang, “Textile Antennas for On-Body Communications:

Techniques and Properties”. The Antennas andPropagation, 2007. EuCAP 2007.

• [4] P. Salonen, Y. Rahmat-Samii, and M. Kivikoski, “Wearable Antennas in the Vicinity of

Human Body”

• [5] M. Tanaka, J. H. Jang, “Wearable Microstrip Antenna”, 2003 IEEE AP-S Int. Symp. Dig.,

volume 2, pp. 704-707, (2003).

• [6] Y. Rahmat-Samii, “Wearable and Implantable Antennas in Body-Centric

Communications”. the Antennas and Propagation, 2007. EuCAP 2007.

• [7] Jaime G. Santas, Akram Alomainy and Yang Hao,” Textile Antennas for On-Body

Communications: Techniques and Properties”

• [8] P. O. Salonen, Y. Rahmat-Samii, H. Hurme, and M. Kivikoski, “Dualband wearable

textile antenna,” in Proc. IEEE Antennas Propag. Int. Symp., 2004, vol. 1, pp. 463–467.

• [9] Seema Dhupkariya*, Vinod Kumar Singh, Arun Shukla ” A Review of Textile Materials

for Wearable Antenna” Journal of Microwave Engineering & Technologies ISSN: 2349-

9001 (online) Volume 1, Issue 3](https://image.slidesharecdn.com/wearabletextileantenna-190509170050/75/Wearable-textile-antenna-51-2048.jpg)

![References

• [10] Tessa Haagenson, Sima Noghanian, Pablo de León, and Yi-hsiang Chang “Wearable

• Textile Antennas Examining the effect of bending on their performance.” IEEE antennas &

Propagation Magazine j u n e 2017

• [11] Tessa Haagenson, Sima Noghanian, Pablo de León, and Yi-hsiang Chang “Textile Antennas for

Spacesuit Applications Design, simulation, manufacturing, and testing of textile patch antennas

for spacesuit applications.” IEEE antennas & Propagation Magazine j u n e 2017

• [12] Rita Salvado, Caroline Loss, Ricardo Gonçalves, and Pedro Pinho “Textile Materials for the

Design of Wearable Antennas: A Survey” Sensors (Basel). 2012; 12(11): 15841–15857 Wearable

Textile Antenna

• [13] Syed Muzahir Abbas*, Karu P. Esselle*, Ladislau Matekovits*‡, Muhammad Rizwan†, Leena

Ukkonen “”On-body Antennas: Design Consideration and Challenges(Invited Paper)2016 URSI

International Symposium on Electromagnetic Theory (EMTS)

• [14] Changrong LiuYong-Xin Guo and Shaoqiu Xiao “A Review of Implantable Antennas for

Wireless Biomedical Devices” Forum for Electromagnetic Research Methods and Application

Technologies (FERMAT)

• [15] Asimina Kiourti “Textile-Based Flexible Electronics for Wearable Applications: from Antennas

to Batteries” 2nd URSI AT-RASC, Gran Canaria, 28 May – 1 June 2018

• [16] Ashok Yadav*, Vinod Kumar Singh, Manu Chaudhary, Himanshu Mohan

• “A Review on Wearable Textile Antenna” Journal of Telecommunication, Switching Systems and

Networks ISSN: 2454-6372

• [17] Amin Khan, Shahid Bashir, Faiz Ullah “Electromagnetic Bandgap Wearable Dipole

antennawith low Specific Absorption Rate” 2018 International Conference on Computing,

Mathematics and Engineering Technologies – iCoMET 2018](https://image.slidesharecdn.com/wearabletextileantenna-190509170050/75/Wearable-textile-antenna-52-2048.jpg)