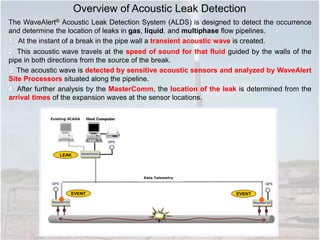

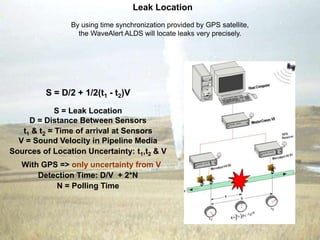

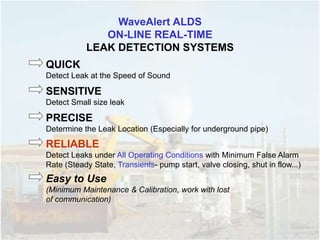

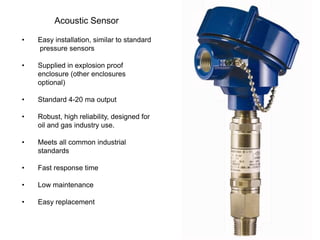

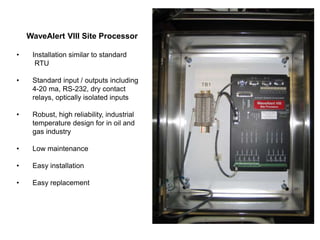

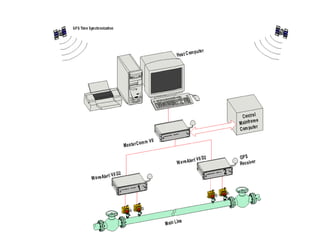

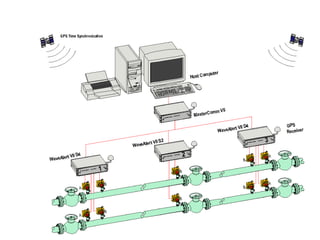

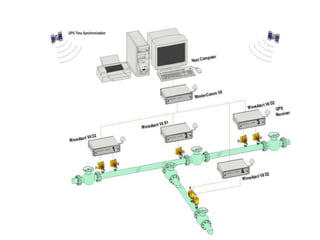

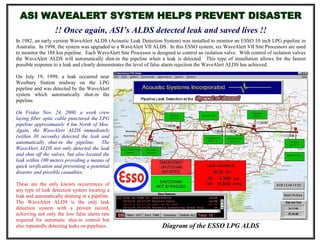

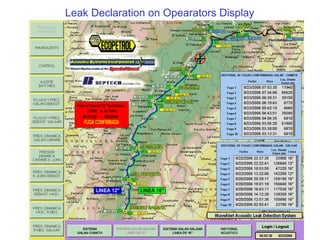

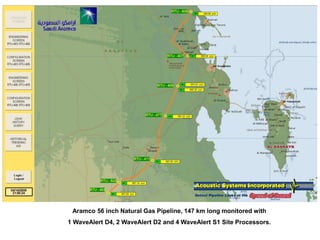

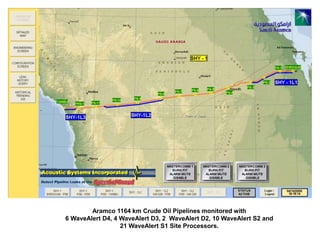

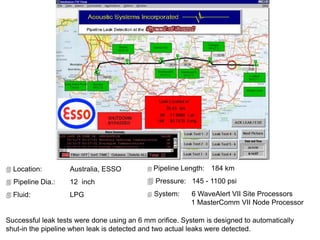

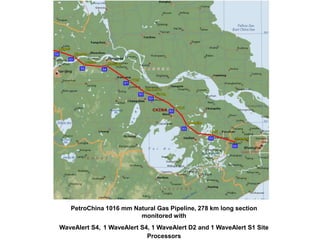

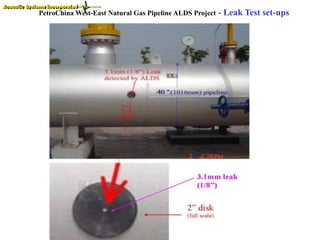

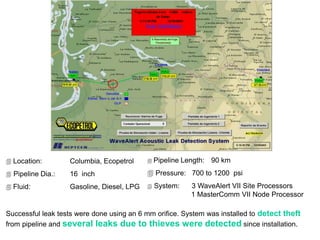

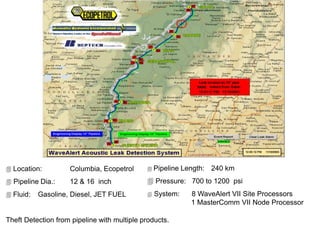

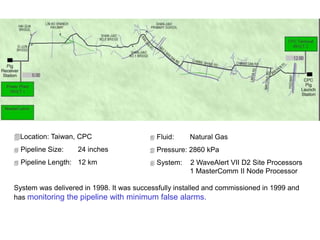

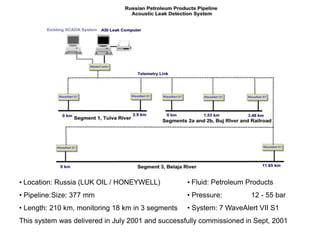

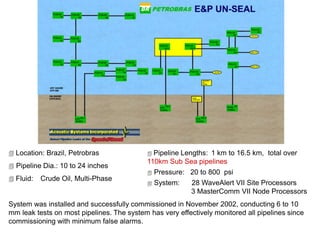

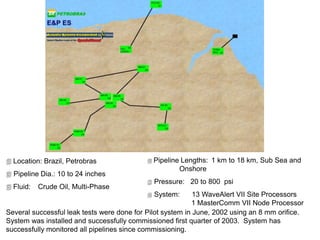

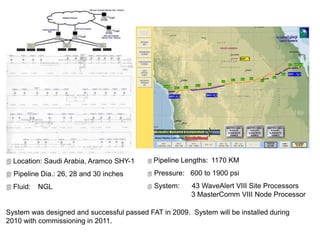

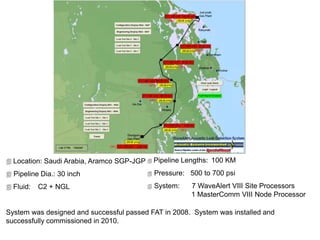

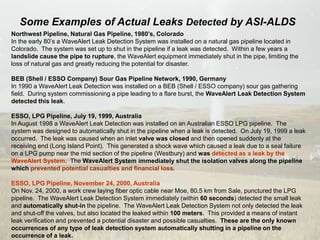

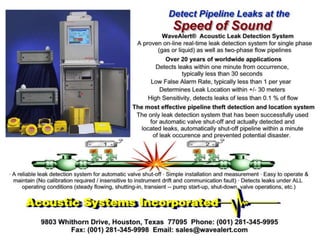

The Wavealert® Acoustic Leak Detection System (ALDS) is designed to detect and locate leaks in various pipeline systems using acoustic sensors to analyze waves created by breaks in the pipes. It offers rapid leak detection within 60 seconds and operates with a low false alarm rate, making it particularly effective for the oil and gas industry. The system has successfully prevented disasters by automatically shutting in pipelines upon leak detection, as demonstrated in multiple real-world cases.