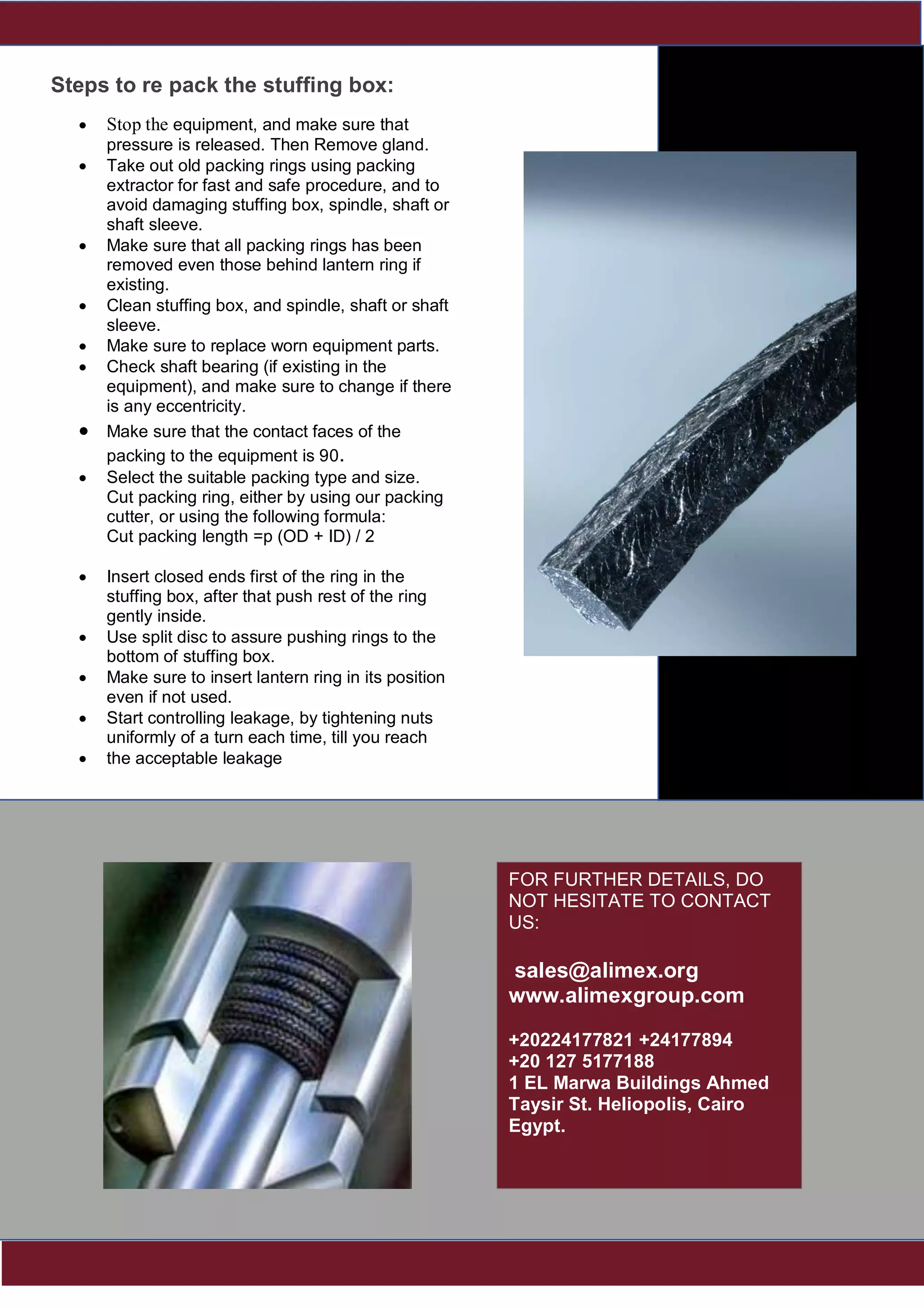

This document provides instructions for replacing gland packing in equipment. It discusses selecting the proper packing material for the application and environment. The steps outlined include removing the old packing, cleaning the stuffing box, inspecting parts for wear, cutting new packing rings to size, inserting the rings with the closed ends first, using a split disc to push the rings into place, installing a lantern ring if needed, and gradually tightening the gland nuts to control leakage. Proper packing replacement can save time and reduce equipment, operation, and power costs through continued effective sealing performance.