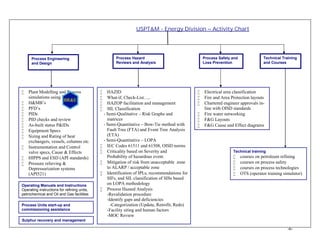

USPTM Activity Chart

- 1. -6- USPT&M - Energy Division – Activity Chart Technical Training and Courses Process Hazard Reviews and Analysis Technical training courses on petroleum refining courses on process safety courses on process technologies OTS (operator training simulator) HAZID What-if, Check-List….. HAZOP facilitation and management SIL Classification - Semi-Qualitative – Risk Graphs and matrices - Semi-Quantitative – Bow-Tie method with Fault Tree (FTA) and Event Tree Analysis (ETA) - Semi-Quantitative – LOPA IEC Codes 61511 and 61508, OISD norms Criticality based on Severity and Probability of hazardous event. Mitigation of risk from unacceptable zone to ALARP / acceptable zone Identification of IPLs, recommendations for SIFs, and SIL classification of SISs based on LOPA methodology Process Hazard Analysis -Revalidation procedure -Identify gaps and deficiencies -Categorization (Update, Retrofit, Redo) -Facility siting and human factors -MOC Review Plant Modelling and Process simulations using ProMax H&MB’s PFD’s PIDs PID checks and review As-built status P&IDs Equipment Specs Sizing and Rating of heat exchangers, vessels, columns etc. Instrumentation and Control valve specs, Cause & Effects HIPPS and ESD (API standards) Pressure relieving & Depressurization systems (API521) Process Engineering and Design Operating Manuals and Instructions Operating instructions for refining units, petrochemical and Oil and Gas facilities Process Units start-up and commissioning assistance Sulphur recovery and management Process Safety and Loss Prevention Electrical area classification Fire and Area Protection layouts Chartered engineer approvals in- line with OISD standards Fire water networking F&G Layouts F&G Cause and Effect diagrams