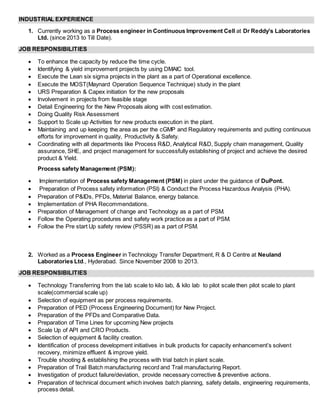

D.Koteswara Rao is seeking a challenging career in a progressive organization where he can enhance his knowledge and skills. He has a B.Tech in Chemical Engineering and 10+ years of experience in process engineering roles. Currently he works as a Process Engineer at Dr. Reddy's Laboratories where he leads continuous improvement and Lean Six Sigma projects. Previously he worked as a Process Engineer scaling up API and CRO products from lab to commercial scale at Neuland Laboratories.