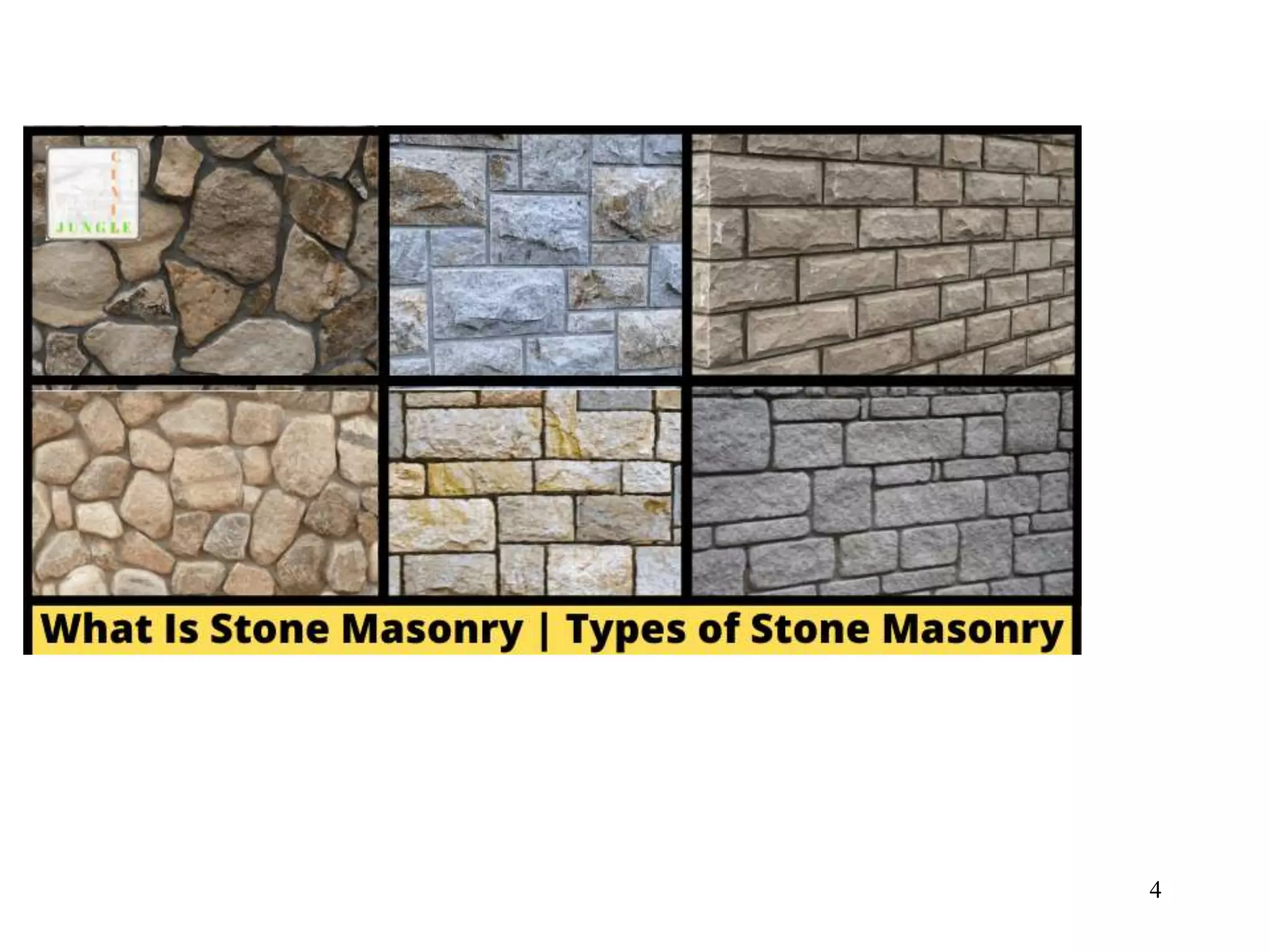

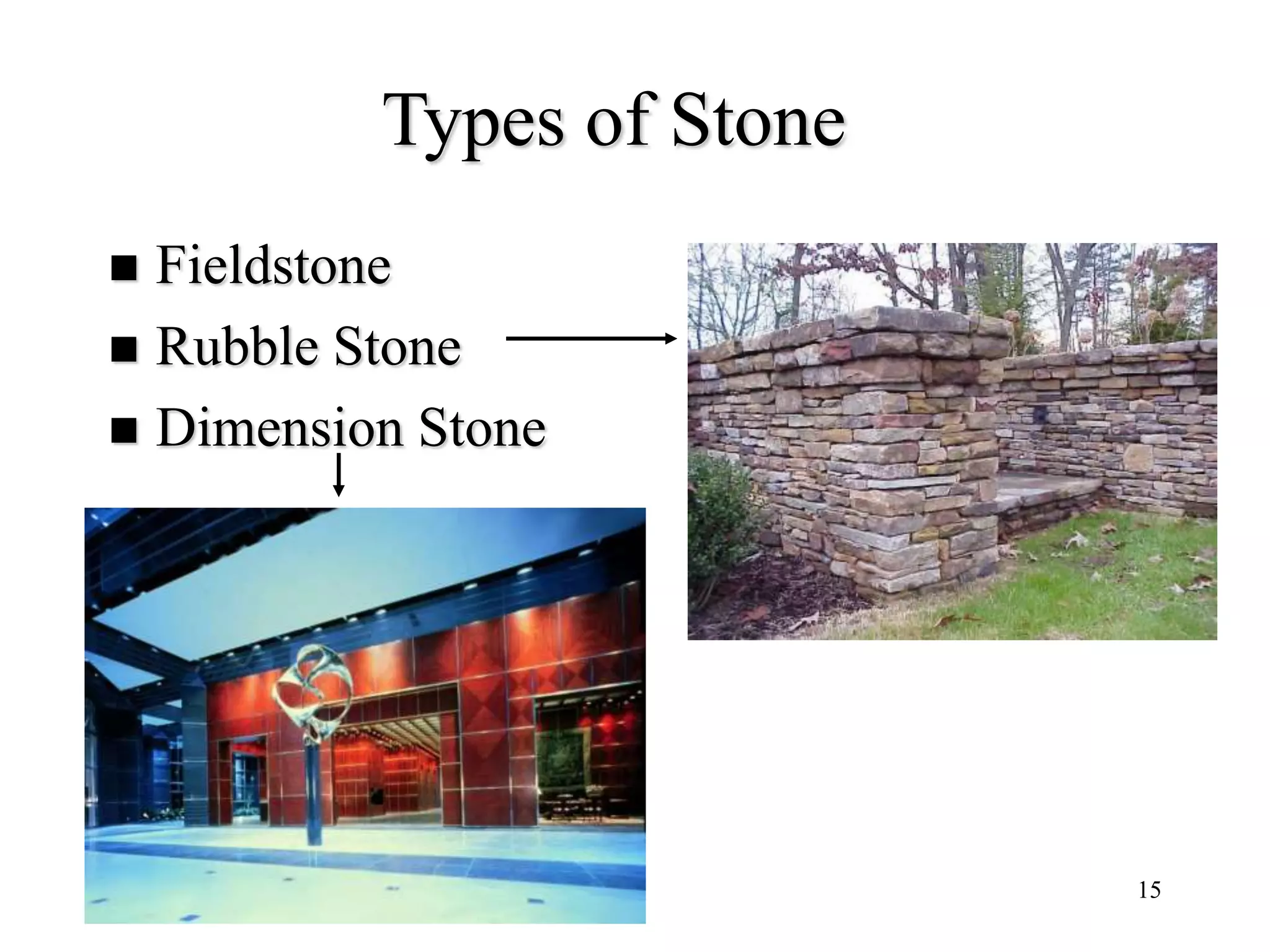

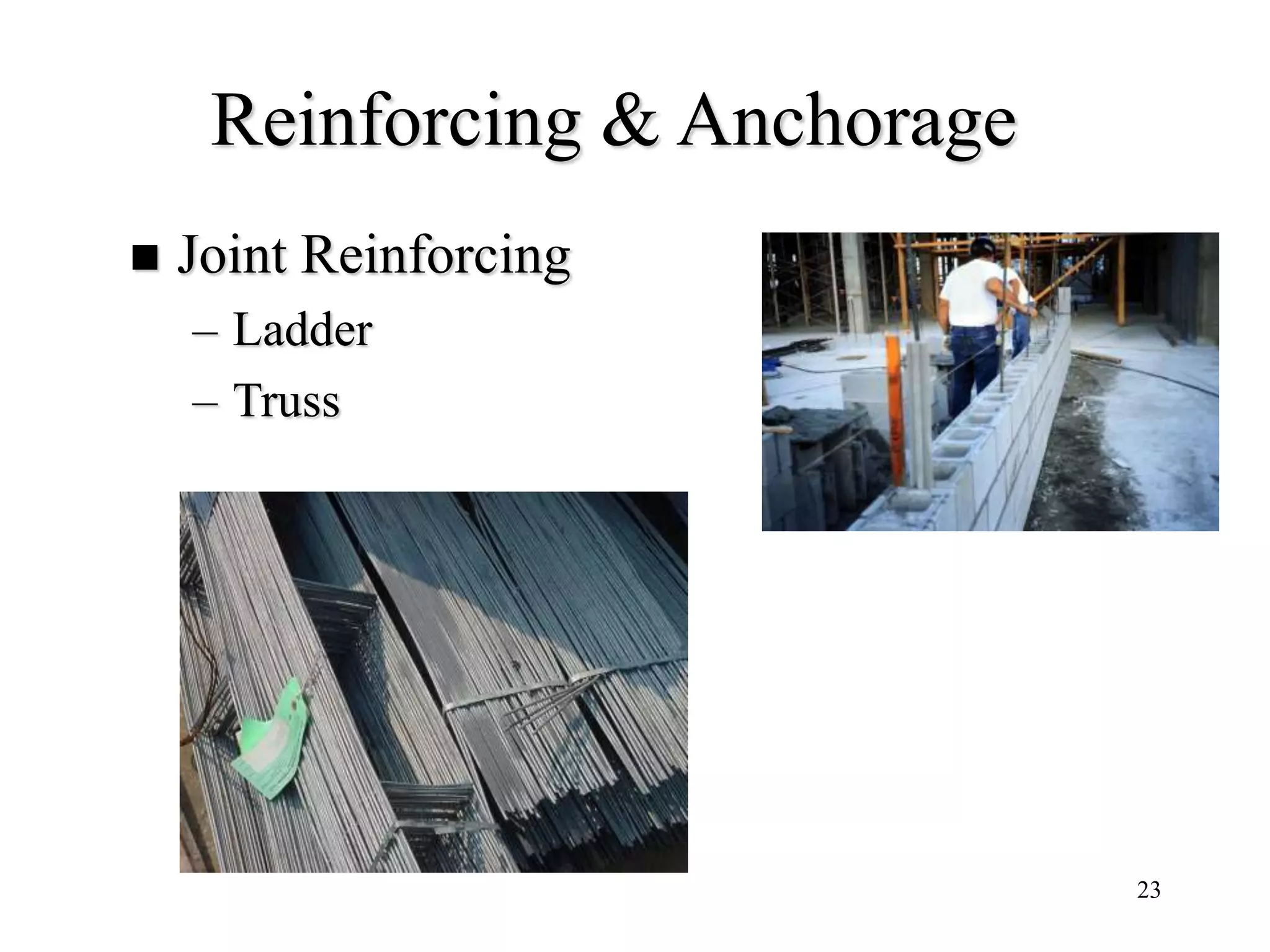

This document discusses different types of stone and reinforced masonry construction. It describes various stones used in masonry like granite, limestone, sandstone and their quarrying. It outlines different types of stone masonry walls like solid, composite and cavity walls. It also discusses precast concrete masonry units, their manufacturing process, sizes and reinforcement techniques like joint reinforcing during construction of masonry walls.