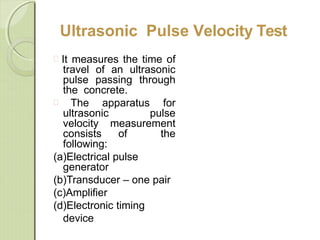

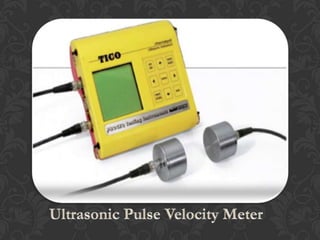

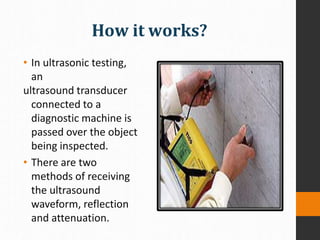

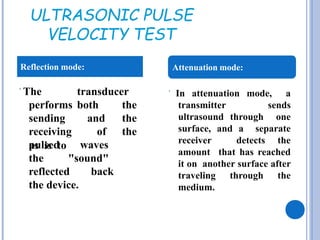

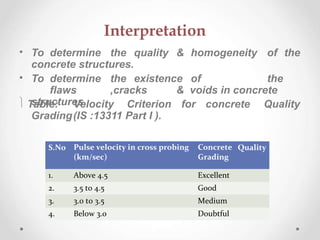

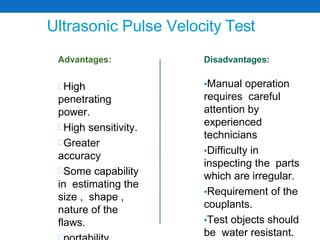

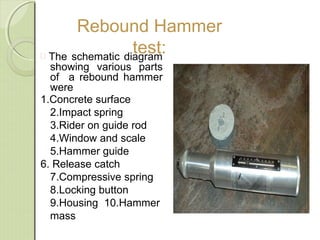

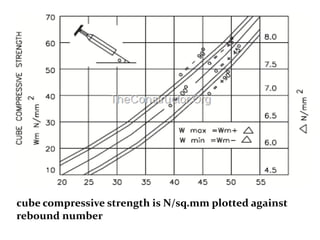

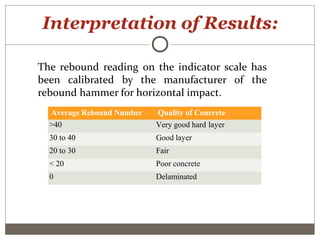

This document discusses non-destructive testing (NDT) methods for evaluating concrete structures. It describes two specific NDT techniques: ultrasonic pulse velocity testing and rebound hammer testing. Ultrasonic pulse velocity testing measures the speed of ultrasonic pulses traveling through concrete to assess quality and detect flaws. The rebound hammer test uses the rebound of an elastic mass to indicate the hardness and estimated compressive strength of concrete surfaces. Both methods can help evaluate concrete without damaging it and provide information on defects, homogeneity, and strength.