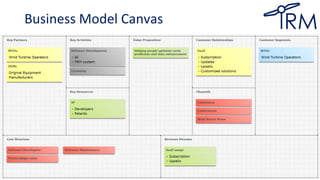

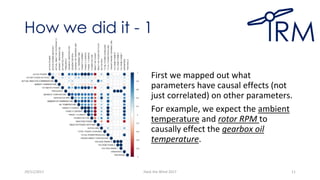

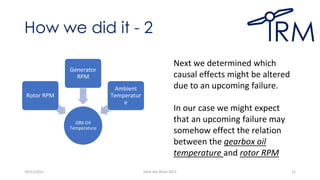

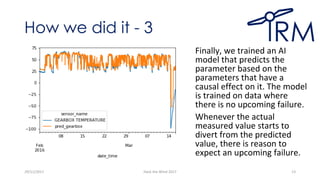

This document describes a project to optimize early failure prediction for wind turbines using data analytics. A team analyzed data from wind turbine control systems to develop an artificial intelligence model that can detect potential failures by noticing deviations between actual and predicted parameter measurements. The goals are to reduce repair and replacement costs from unexpected failures and make relevant data accessible to operators and professionals to improve efficiency. The team mapped causal relationships between operational parameters and trained a model to predict values based on those relationships to flag unexpected divergences that may indicate upcoming issues.