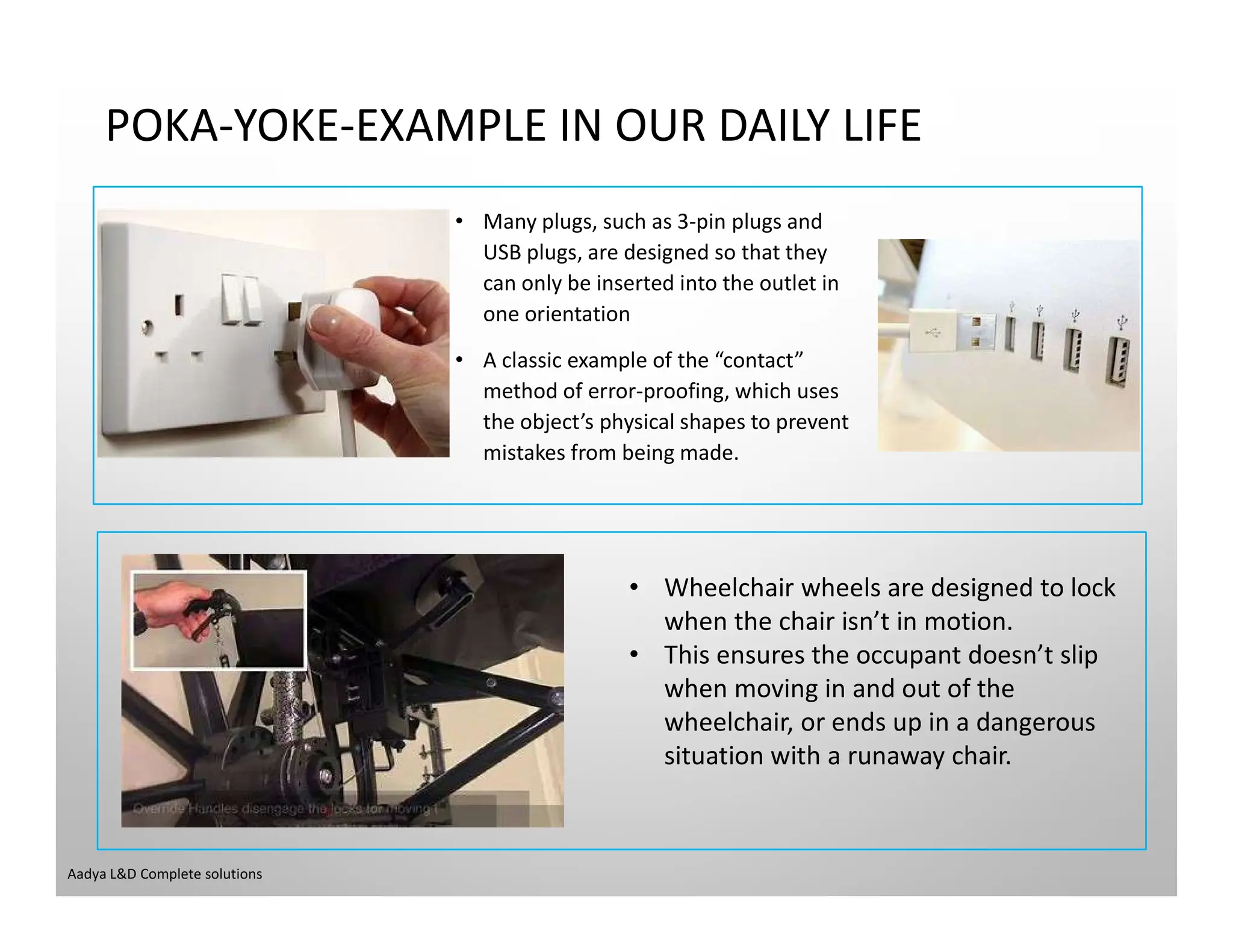

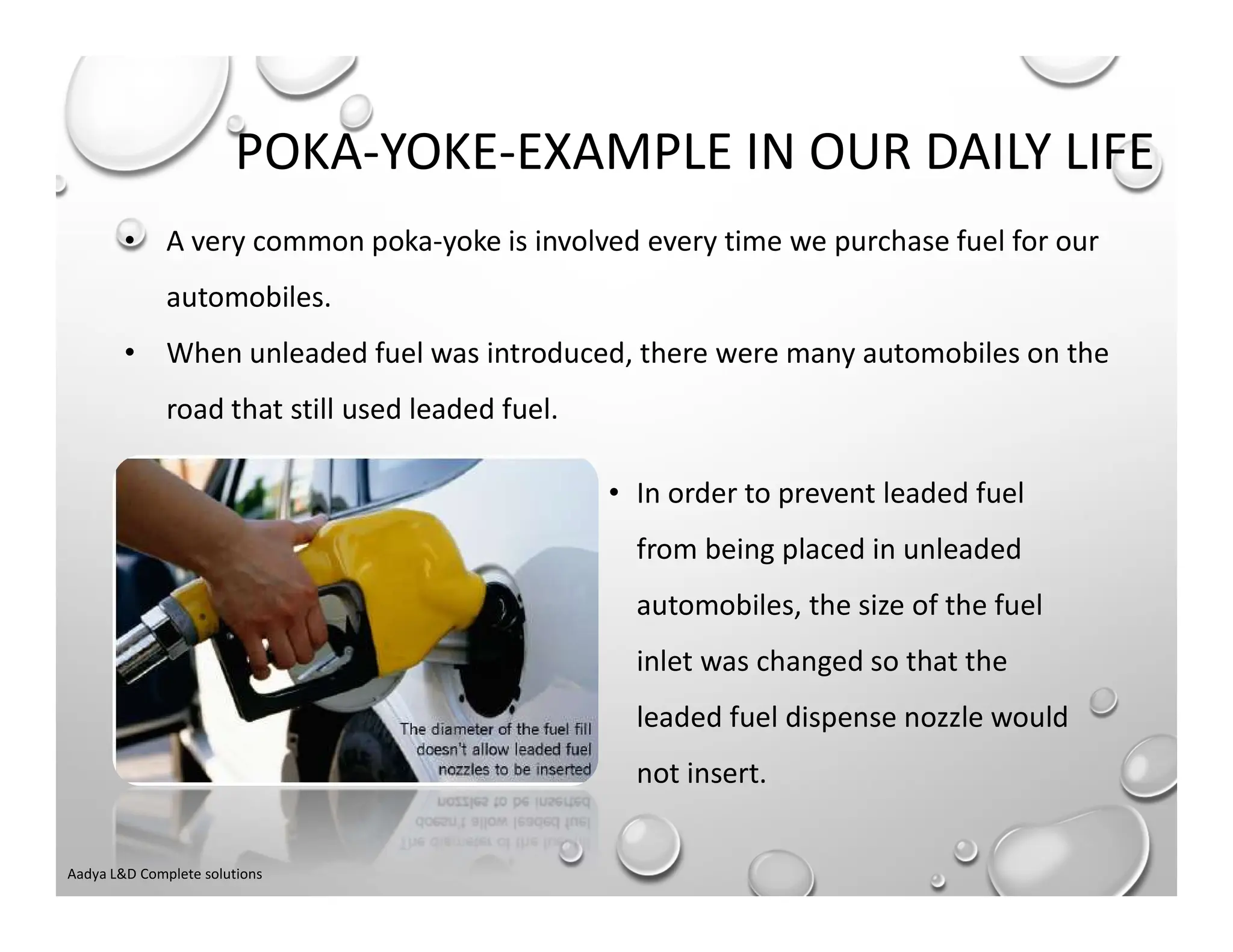

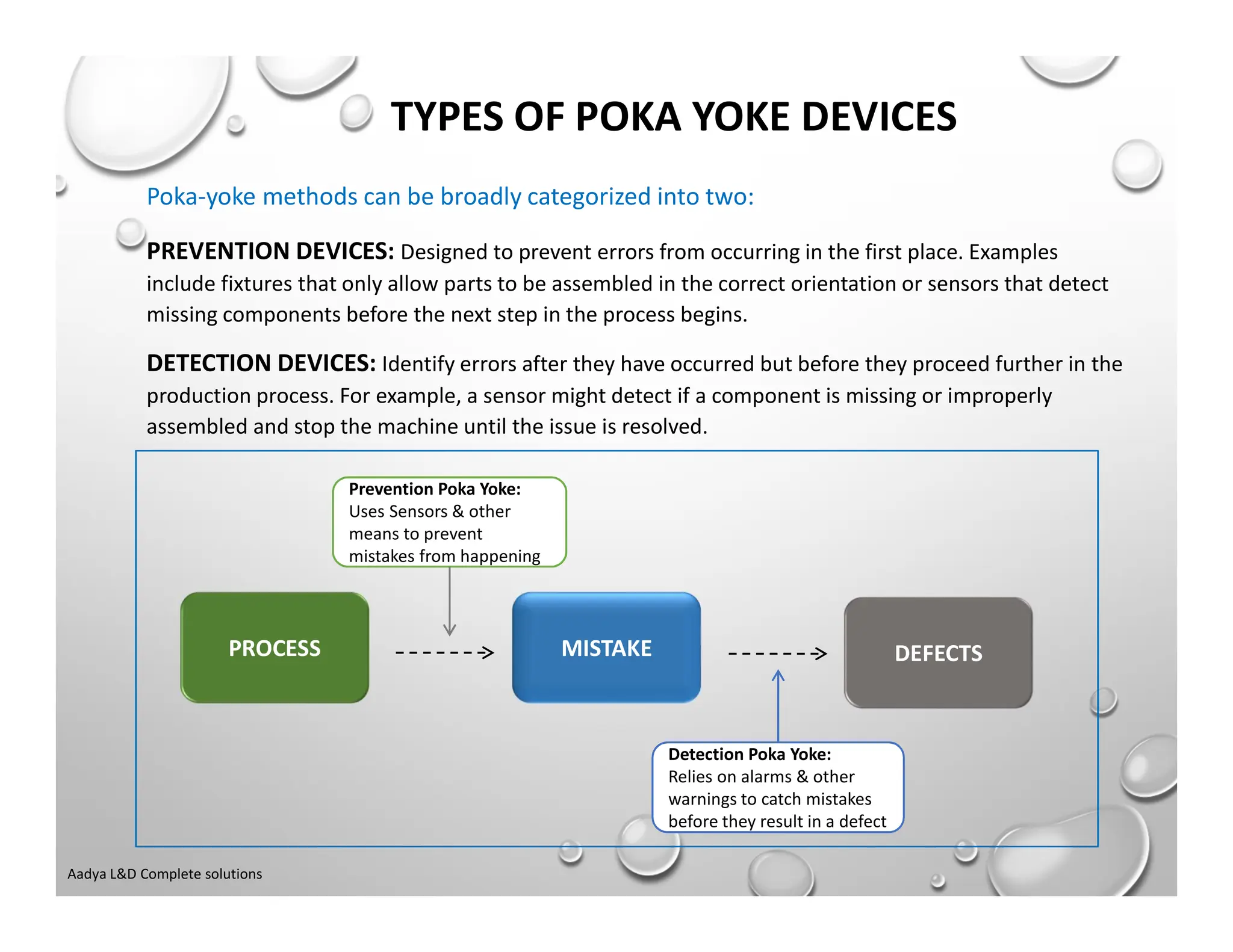

The document provides a comprehensive overview of Poka Yoke, a Japanese technique for mistake-proofing processes to prevent human error and enhance quality control in manufacturing. It includes examples, types of Poka Yoke devices, implementation strategies, and the benefits such as reduced defects, cost savings, improved efficiency, and enhanced customer satisfaction. Additionally, it discusses real-world applications and case studies demonstrating Poka Yoke's effectiveness in various industries.