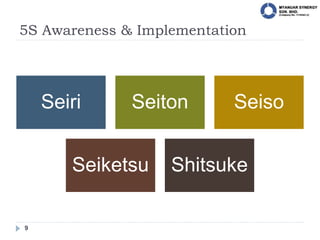

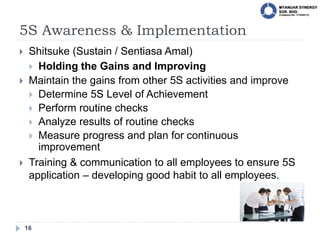

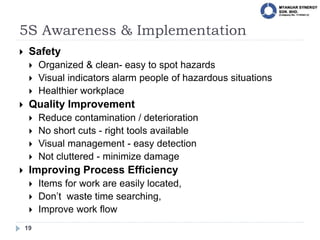

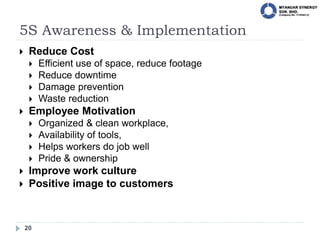

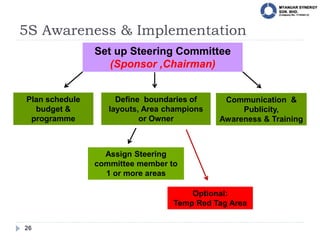

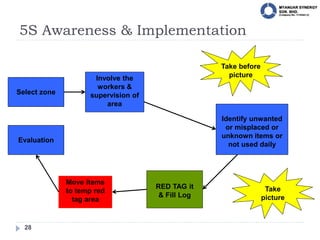

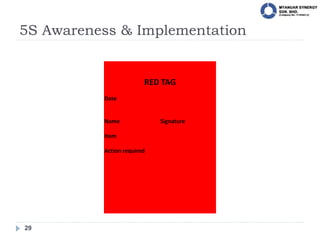

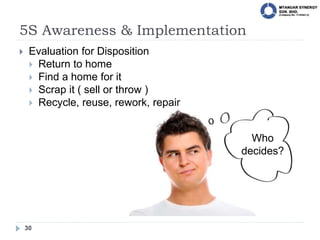

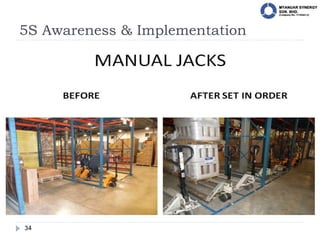

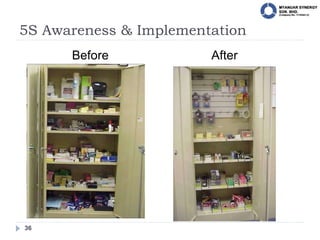

The document outlines the principles, history, and implementation of the 5S methodology for workplace organization, which includes sorting, systemizing, sanitizing, standardizing, and sustaining. It emphasizes the benefits of 5S in improving efficiency, safety, and workplace culture while providing a structured approach for effective implementation. Participants will learn to understand and apply 5S principles to enhance productivity in their organizations.