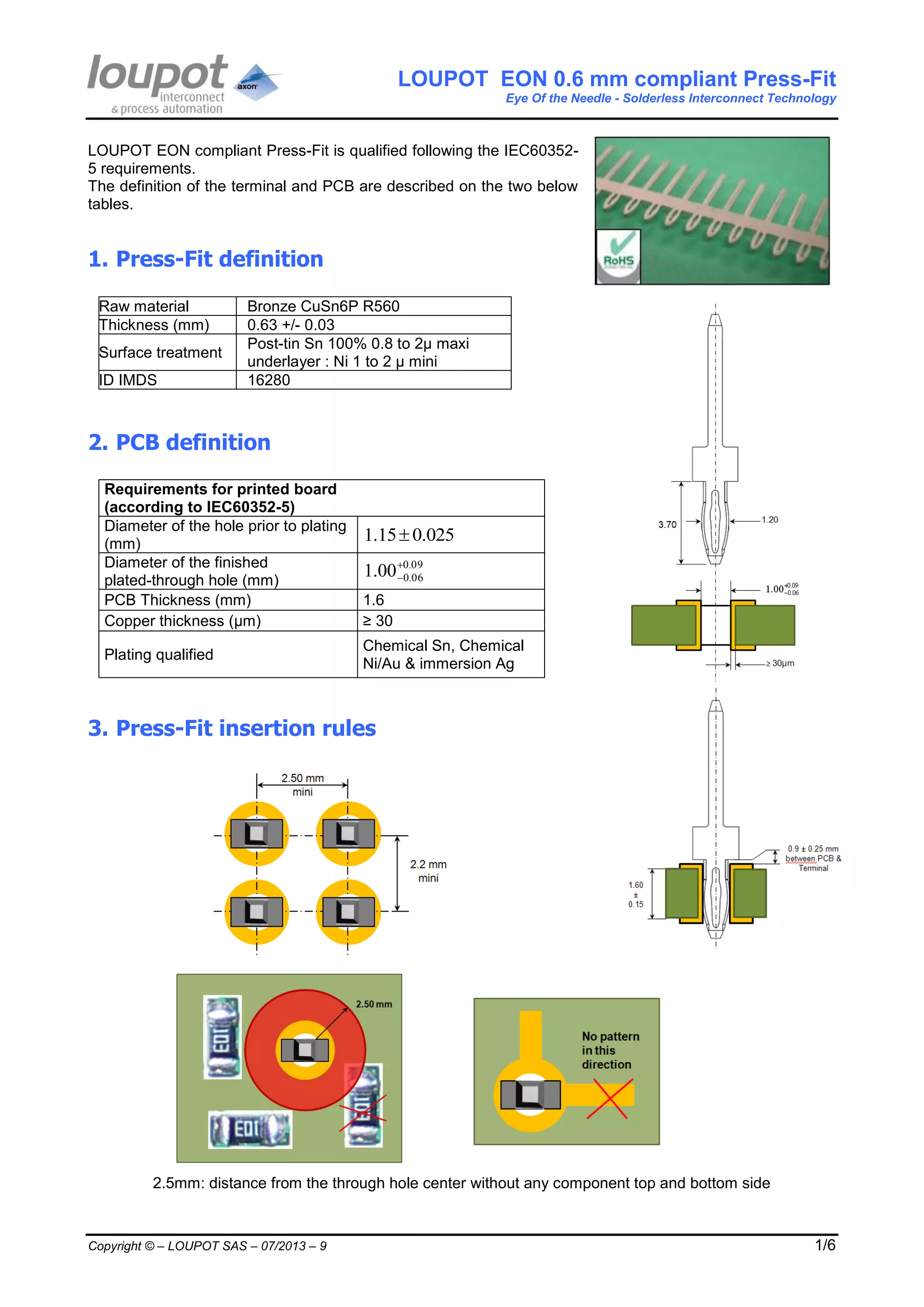

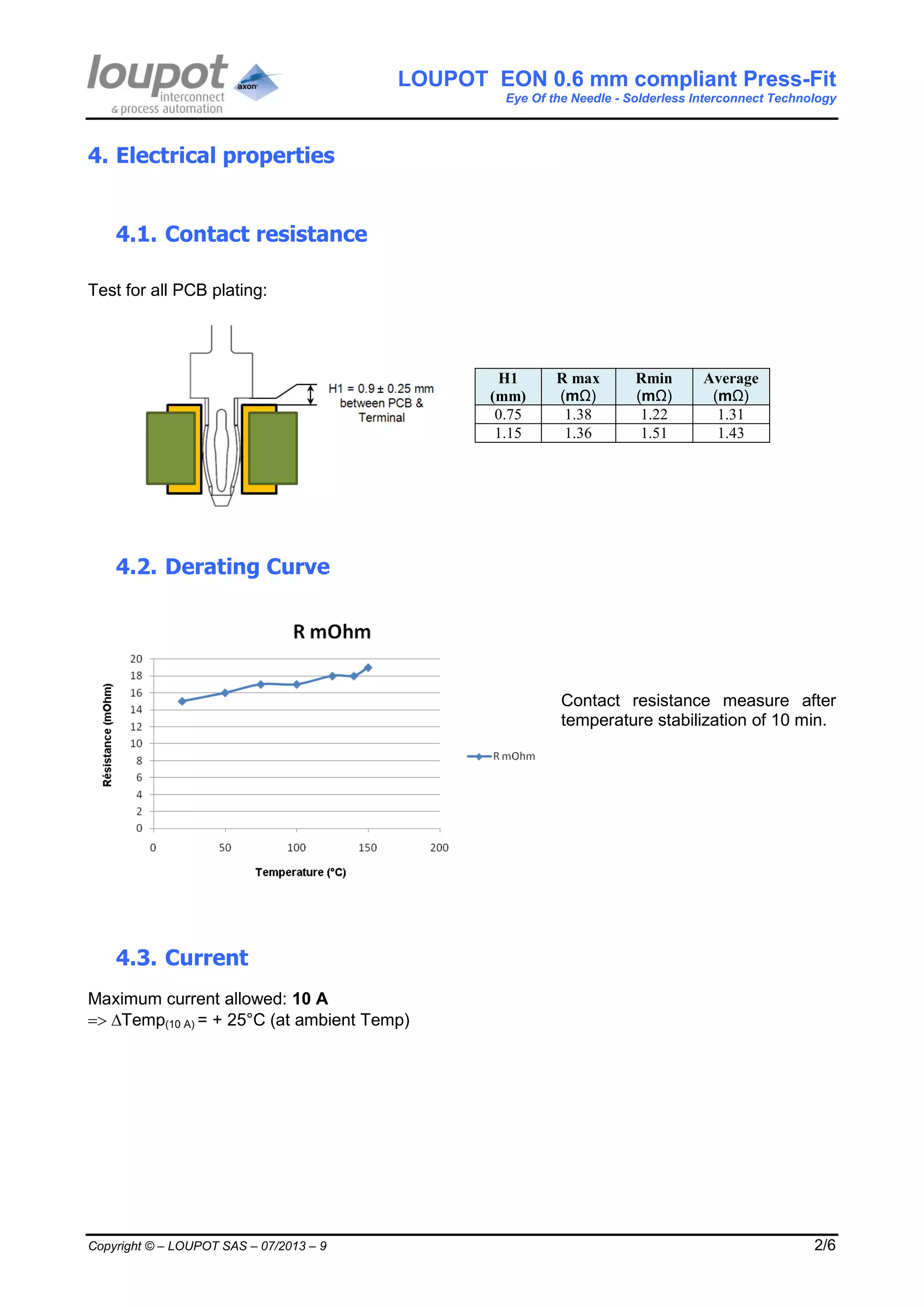

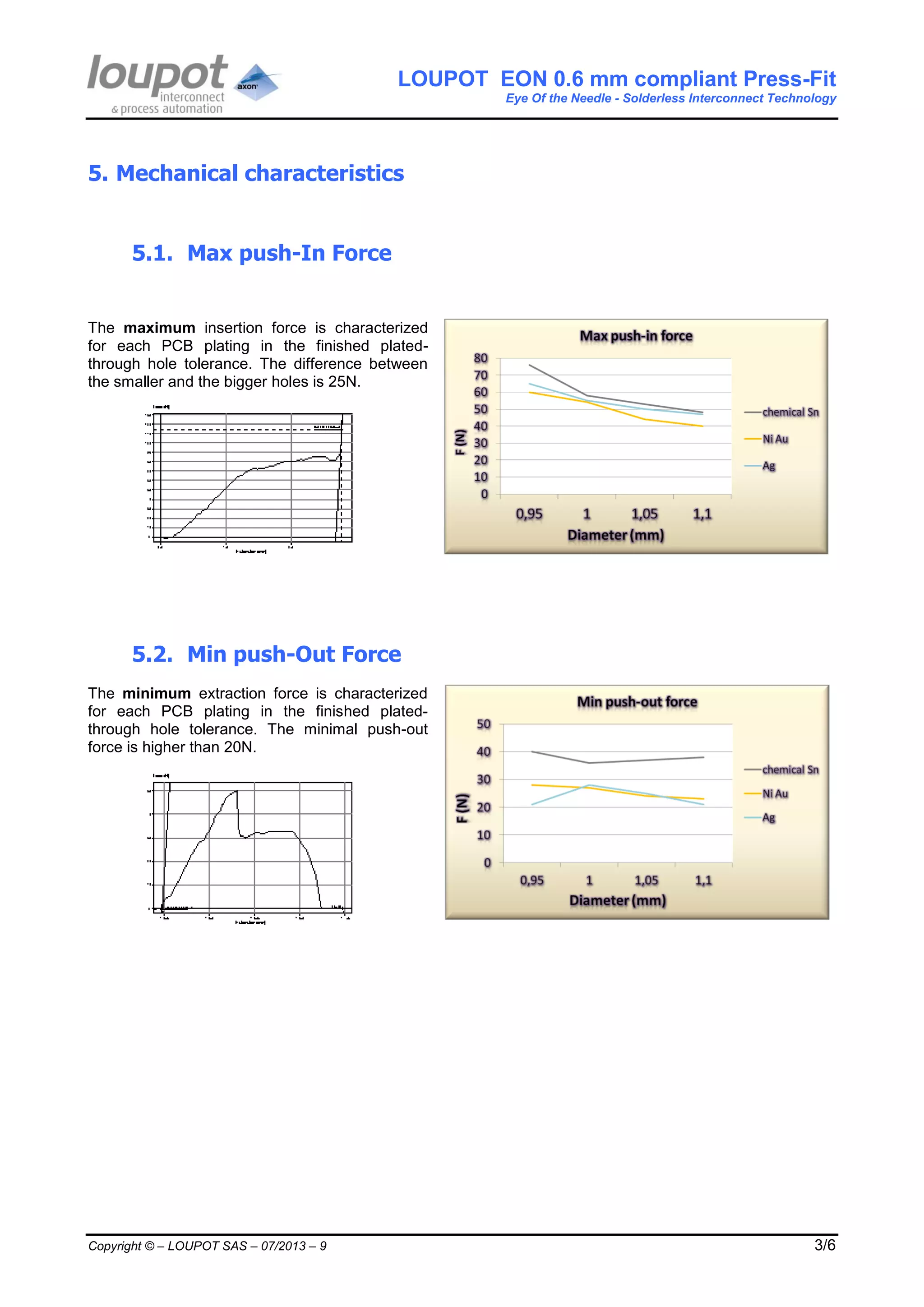

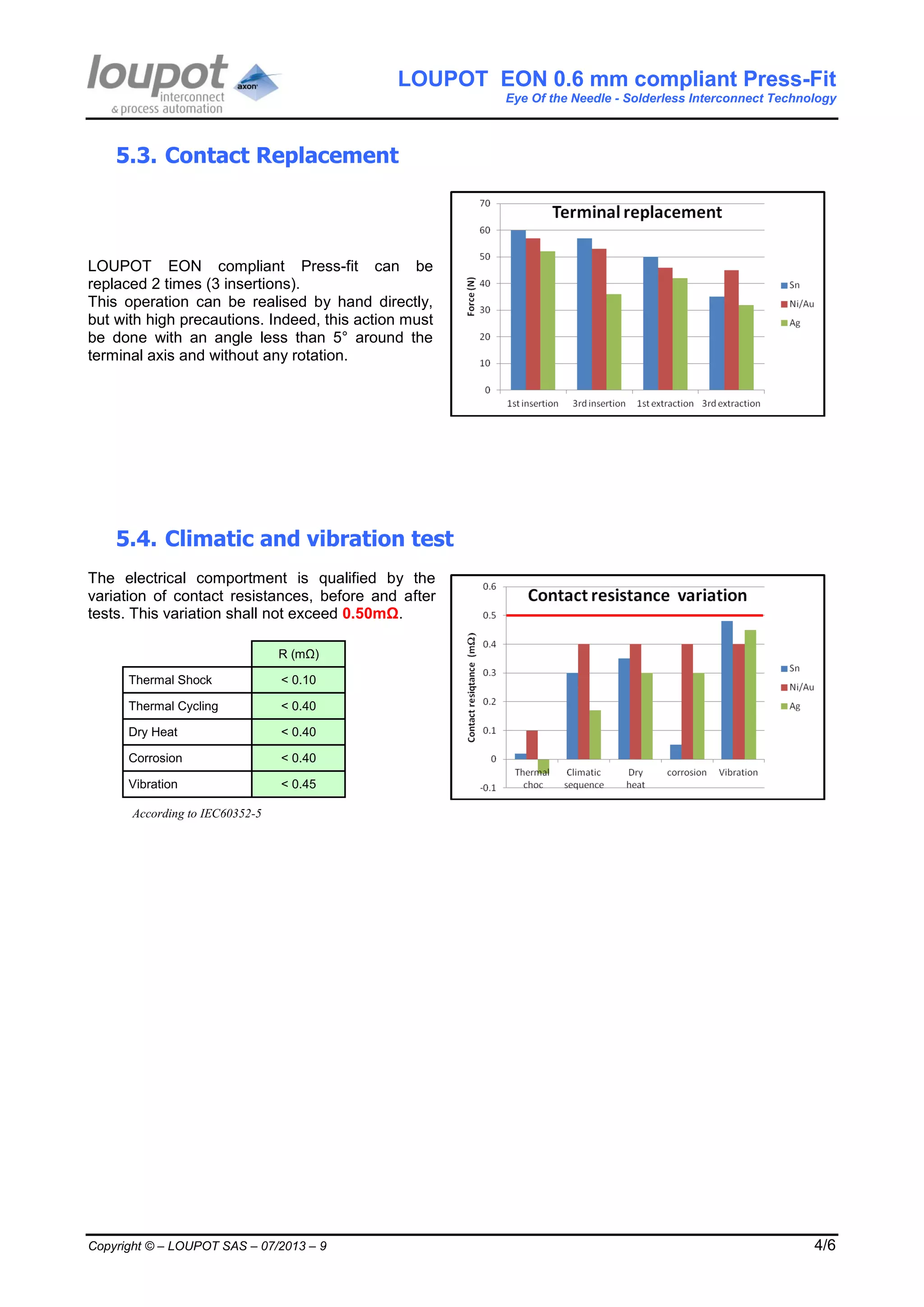

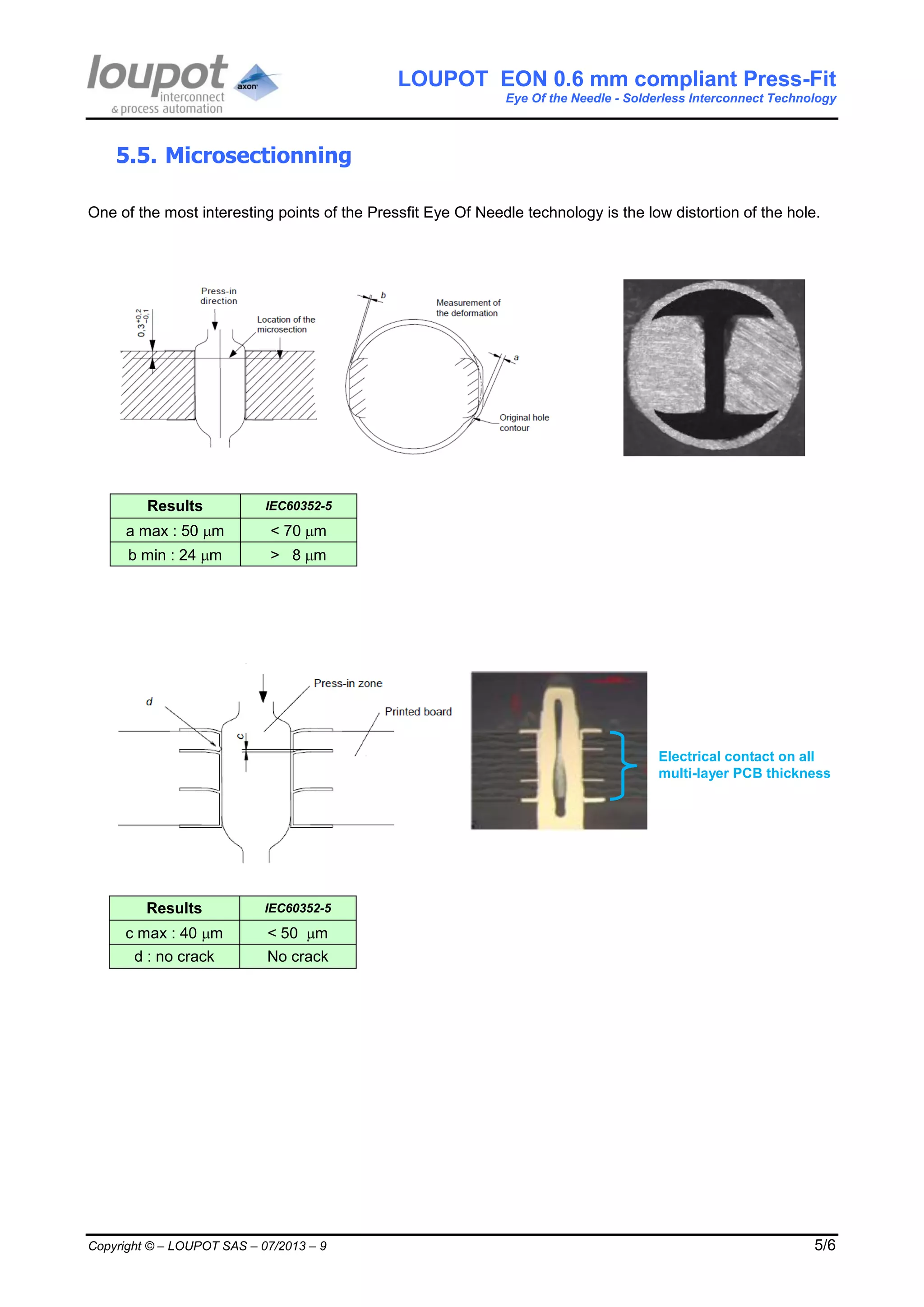

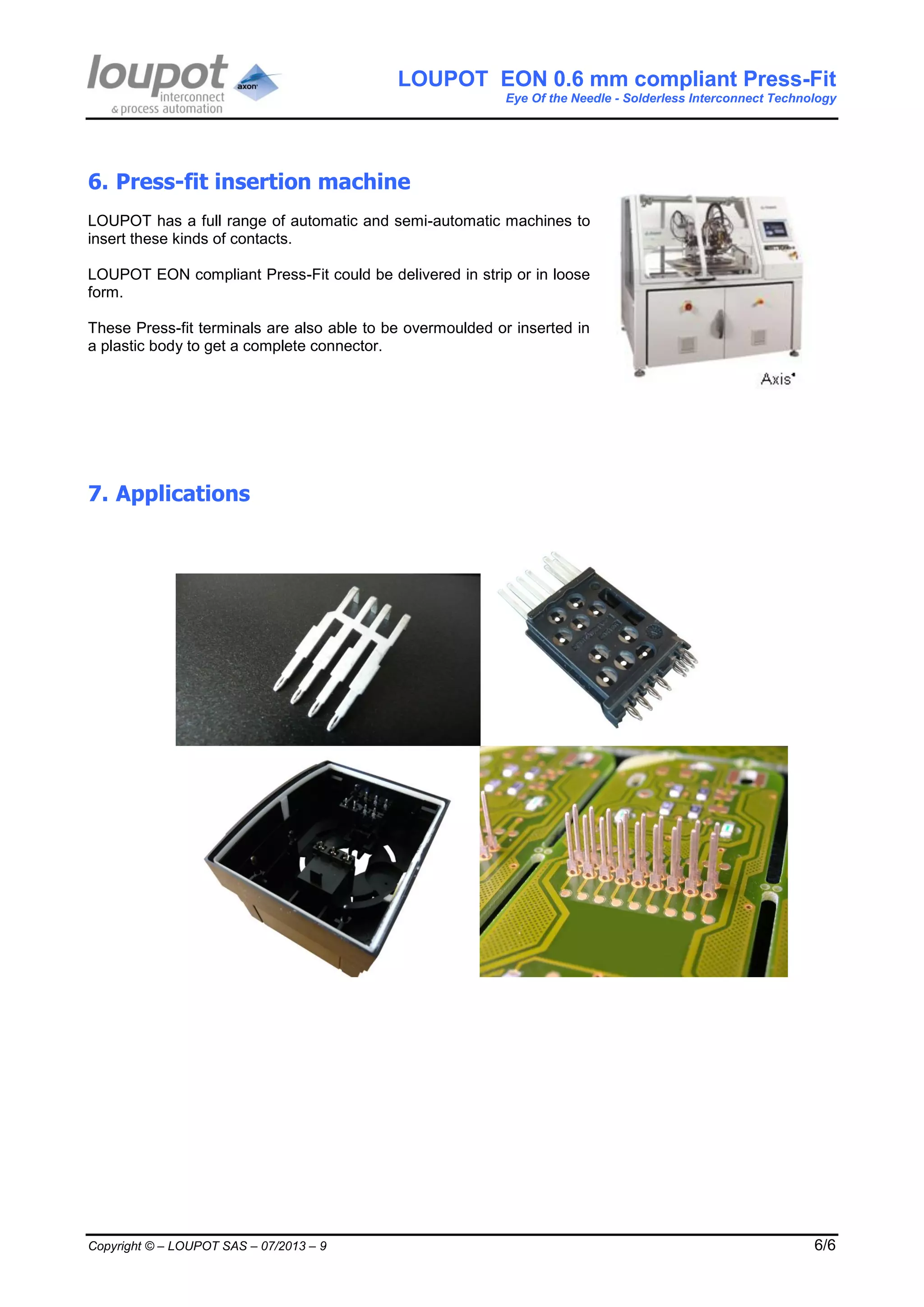

The document describes LOUPOT EON 0.6 mm compliant press-fit technology for solderless interconnects. It defines the press-fit terminal dimensions and insertion rules, and specifies the printed circuit board requirements. It also summarizes the technology's electrical and mechanical characteristics such as low contact resistance, push-in/out forces, replacement capability, and passes climatic/vibration tests.